Sierra Monitor Corporation 5100-06-IT User Manual

Page 48

Model 5100-XX-IT Toxic Gas Sensor Module

Page: 44

8.7

APPENDIX G1: 5100-25-IT GAS SENSOR MODULE

1. Calibration of 5100-25-IT (Supplement to Instructions in Section 6)

2. Equipment Required

The following tools and equipment will be required for calibration:

-

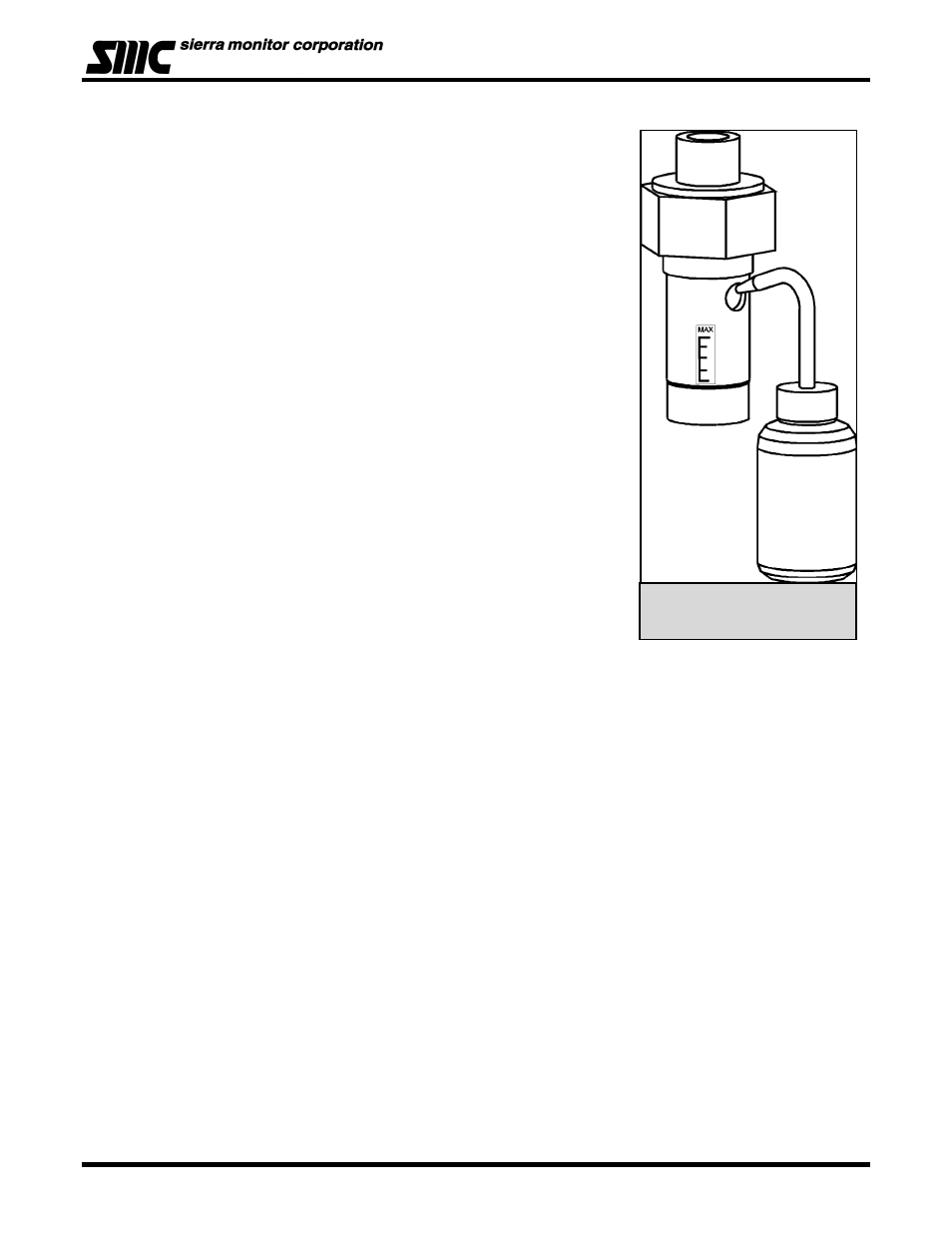

Permeation Device Calibrator (Model 9210-00), with

Ammonia Permeation Tube (Model 9211-09).

-

Calibration Adapter (Model 5358-01)

3. Permeation Device Calibrator Operation

The calibrator is a portable device with a pump that operates from a

1.5 V alkaline size D battery. A fresh battery should allow 8 hours of

continuous operation. The permeation device will probably be

shipped separately, usually in a pipe with screw cap ends, one of

which will be marked for opening. The permeation device should

come fitted with a scrubber, but, as a precaution, open the pipe and

remove the permeation device in a well ventilated area.

1. Remove the scrubber from the permeation device and attach the

device to the stainless steel “Tee” assembly inside the calibrator

box. Tighten the connection with a wrench, with the device

resting inside one of the openings in the rack.

2. Close the door of the calibrator and turn on the pump switch.

3. Set the flow rate for the desired ppm of ammonia. The desired

flow rate for calibration of the Model 5100-25-IT is 300-500

cc/min. and the concentration range should be set between the

high alarm point and 100 ppm full scale.

The carrier gas flow rate can be calculated from the formula:

P = (CxF)/K

Where P = the permeation rate in nanograms/min., and C = ppm of span gas, F = carrier gas flow rate in

ml./min. and K = 1.437 for ammonia. The permeation rate for the temperature read on the front of the

calibrator can be obtained from permeation rate vs. temperature chart.

4. Run the gas calibrator for 30 min. before attaching the output hose to the ammonia sensor.

5. When the use of the calibrator is completed, do not turn off the pump unit until the permeation device

has been removed from the “Tee” and the gas scrubber reattached. Failure to remove the permeation

device when the pump has been turned off will contaminate the system with high amounts of the

permeating gas and result in erroneous concentrations. The device, with scrubber, can be stored in the

storage rack overnight, but should not stay in the gas calibrator for longer storage periods.

4. Sensor Assy. Rebuild Procedure

Follow procedures outlined in Electrolyte/Membrane Replacement (See Fig. 8-5)

The electrolyte needs to be replaced at least every six months, or if there is evidence of low sensor

output. The membrane and O-Ring should be replaced at the same time that the electrolyte is

replaced.

5. Equipment Required

- Electrolyte Recharge Kit (SPX27057 for Model 5100-25-IT and SPX27061 for Model 5100-26-

IT) consisting of the electrolyte, package of 5 membranes, 5 0-Rings and alcohol wipes to clean

the electrode.

- Tweezers to aid in removing and replacing the membrane

Figure 8 - 4: Module

Components