Installation and user manual – MGE UPS Systems EX 7RT User Manual

Page 37

Installation and User Manual

2.8

Connecting the Input and Output Power Cables to the Input/Output Box

WARNING

This type of connection must be carried out by qualified electrical personnel.

Before carrying out any connections, check that battery circuit breaker

is OFF

and that the upstream protection devices (Normal and Bypass AC

sources) are open (OFF).

EX 5/7/11 RT UPS always comes from factory with Normal and Bypass AC inputs

already connected together, using a shunt.

2.8.1

Flexible Cordage and Conduit Installations

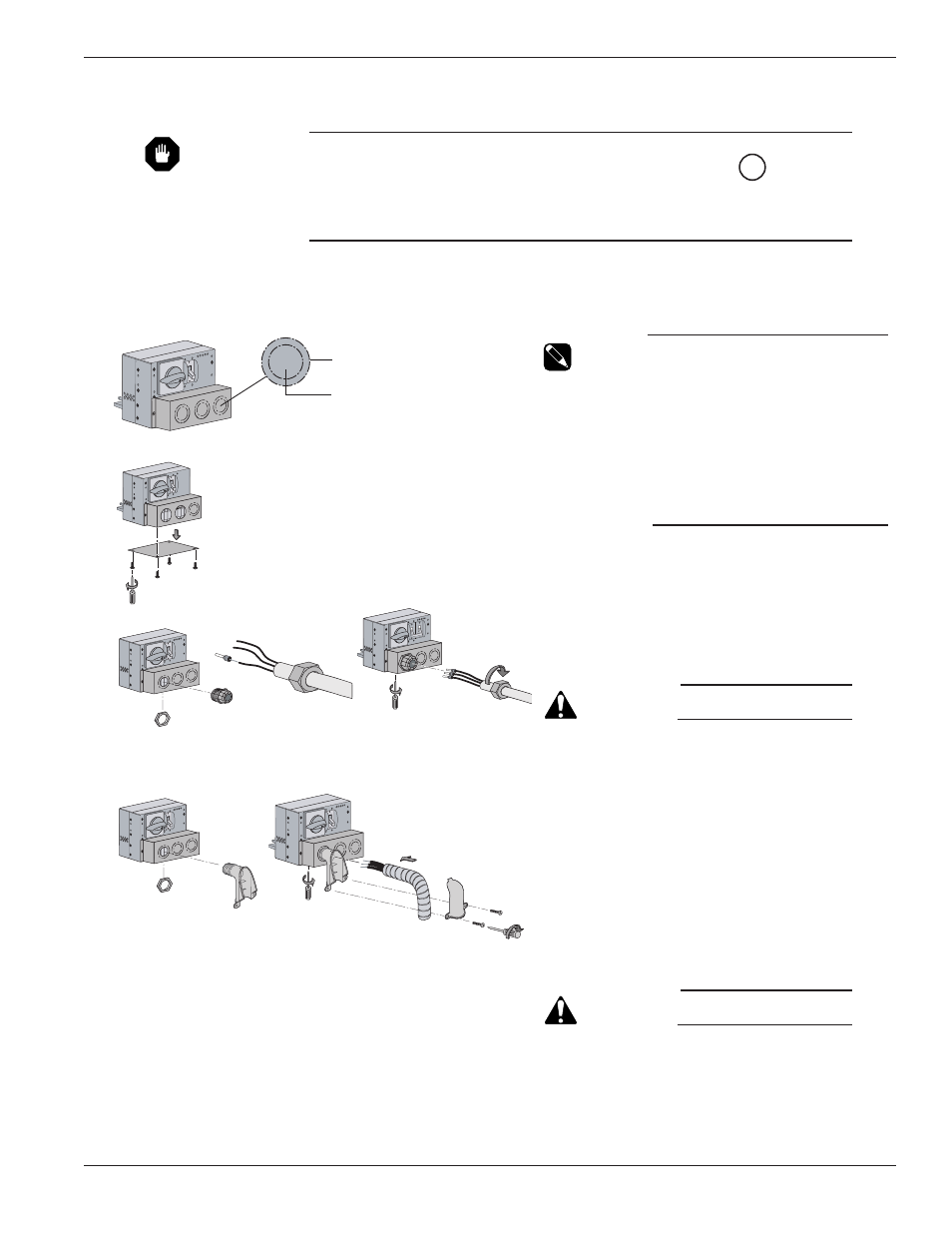

Figure 2-12a: Step 1 & 2; Typical plastic and metal coupling installations.

14

Installation

2 — 13

86-86000-00 A01

OFF

0

OFF

0

3. Typical Flexible Cordage Installation

Inner circle is for

Metal strain relief

Outer circle is for

Plastic strain relief

(a)

(b)

4.

Typical 90

°

Metal Conduit Installation

(a)

Terminal Block Cover

(c)

(d)

I/O BOX

NOTE: Place lug ring inside

the terminal block cover.

Screw coupling into lug ring.

NOTE: Place lug ring inside

the terminal block cover.

Screw coupling into lug ring.

(b)

(c)

(d)

OFF

O

OFF

O

OFF

O

OFF

O

2

OFF

O

1

1.

Knockout die stamp circles.

NOTE

Terminal cable capacity:

Max. 4 AWG (11kVA), 6 AWG

(5/7kVA).

Knockout die stamp

circles (on terminal block

cover) have two sizes that fit

either plastic or metal

coupling. Plastic coupling is for

flexible cordage

and metal coupling is for solid

wires. Knock out appropriate

circle for your application.

2.

Remove bottom cover plate as shown.

3.

Typical plastic strain relief installation:

a)

Secure strain relief body onto the

knockout plate.

b)

Strip the jacket back to expose the

three wires. Strip the insulation of

each wire back 1/2”. Insert the

ferrules as shown to each wire.

CAUTION:

Always connect the

earth ground wire first.

c)

Slide the cordage into the strain relief

and secure the wires into the

terminal blocks using the guide

printed on bottom of I/O box.

d)

Secure the cordage retainer nut.

4.

Typical 90° metal conduit installation.

a)

Secure strain relief body to knockout

plate as shown.

b)

Insert three wires through flexible

conduit and bend 90°.

c)

Strip the insulation back 1/2” to

expose solid wire and secure three

wires into the terminal block using

guide printed on bottom of I/O box.

CAUTION:

Always connect the

earth ground wire first.

d)

Install strain relief cover using two

screws.