Fp1969 firestop w room above, Fp1970 firestop no room – Monessen Hearth LEXINGTON LX32DV User Manual

Page 22

22

51D0528

LX Series Direct Vent Gas Fireplace

VeNtING INStALLAtIoN

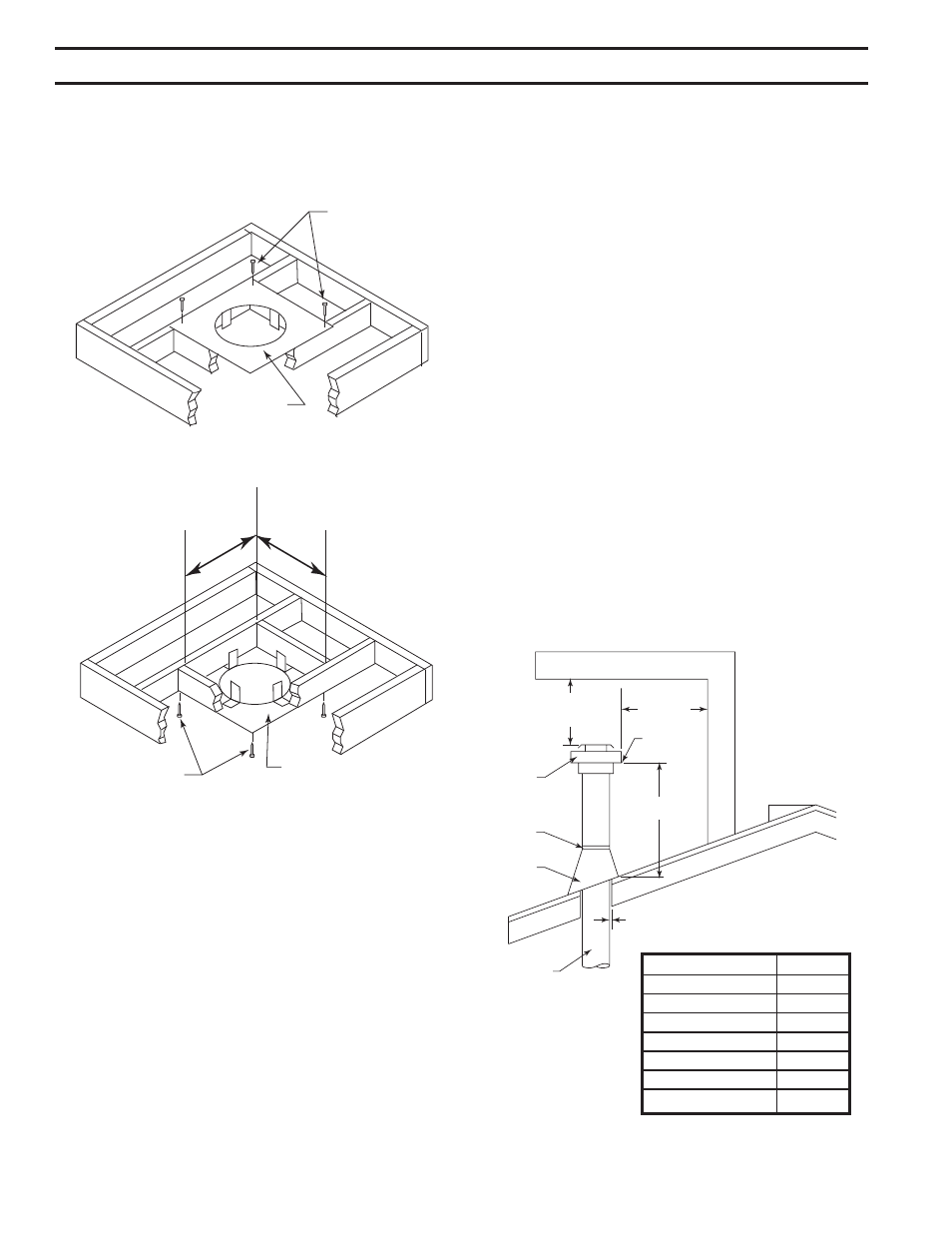

side. This prevents loose insulation from falling into the

required clearance space. Figure 30. Otherwise, install

firestop below the framed hole. The firestop should be

installed with no less than three nails per side. Figure

35.

FP1969

firestop w room above

Figure 30 -

If area above is a room, install firestop above framed

hole as shown

Firestop

Nails

FP1969

9

1

/

2

"

9

1

/

2

"

FP1970

firestop no room

Figure 31 -

If area above is not a room, install firestop below

framed hole as shown

Nails

Firestop

FP1970

2. Assemble the desired lengths of pipe and elbows nec-

essary to reach from the burner system flue up through

the firestop. Be sure pipe and elbow connections are

fully twist-locked. Page 17, Figure 16

3. Cut a hole in the roof using the locating hole as a center

point. (Cover any exposed open vent pipes before cut-

ting hole in roof). The 9Z\x" x 9Z\x" (241 x 241 mm) hole

must be measured on the horizontal. Actual length may

be larger depending on the pitch of the roof. There must

be a 1" minimum clearance from the vent pipe to com-

bustible materials. (Insulation should be considered a

combustible material) Frame the opening as shown on

Page 17, Figure 15.

4. Connect a section of pipe and extend up through the

hole.

Note: If an offset is needed to avoid obstructions, you

must support the vent pipe every three (3) feet. Use wall

straps for this purpose. Refer to Figures 27 & 29. Whenever

possible, use 45° elbows instead of 90° elbows. The 45°

elbow offers less restriction to the flow of the flue gases

and intake air.

5. Place the flashing over the pipe section(s) extending

through the roof. Secure the base of the flashing to

the roof and framing with roofing nails. Be sure roofing

material overlaps the top edge of the flashing. There

must be a 1" clearance from the vent pipe to combustible

materials.

6. Continue to add pipe sections until the height of the vent

cap meets the minimum requirements below.

Note: You must increase vent height for steep roof

pitches. Nearby trees, adjoining roof lines, steep pitched

roofs, and other similar factors may cause poor draft or

down-drafting in high winds. Increasing the vent height

may solve this problem.

Note: If the vent pipe passes through any occupied areas

above the first floor, including storage spaces and closets,

you must enclose pipe. You may frame and sheetrock the

enclosure with standard construction material. Make sure

to meet the minimum allowable clearances to combustibles.

Do not fill any of the required clearance spaces with

insulation.

2 ft.

Min.

2 ft. Min.

X

12

H*

FP1971

Min chimney clearance

Termination

Vent

Storm

Collar

Flashing

Lowest

Discharge

Opening

Concentric

Vent Pipe

1” Minimum Clearance to

Combustibles

FP1971

Horizontal Overhang

Figure 32 -

Minimum Chimney

Clearance

Roof pitch

h (feet)

Flat to 6/12

1.0

Over 6/12 to 7/12

1.25

Over 7/12 to 8/12

1.5

Over 8/12 to 9/12

2.0

Over 9/12 to 10/12

2.5

Over 10/12 to 11/12

3.25

Over 11/12 to 12/12

4.0

*H - Minimum height from roof to

lowest discharge opening of vent