Warning – Monessen Hearth LEXINGTON LX32DV User Manual

Page 17

51D0528

17

LX Series Direct Vent Gas Fireplace

VeNtING INStALLAtIoN

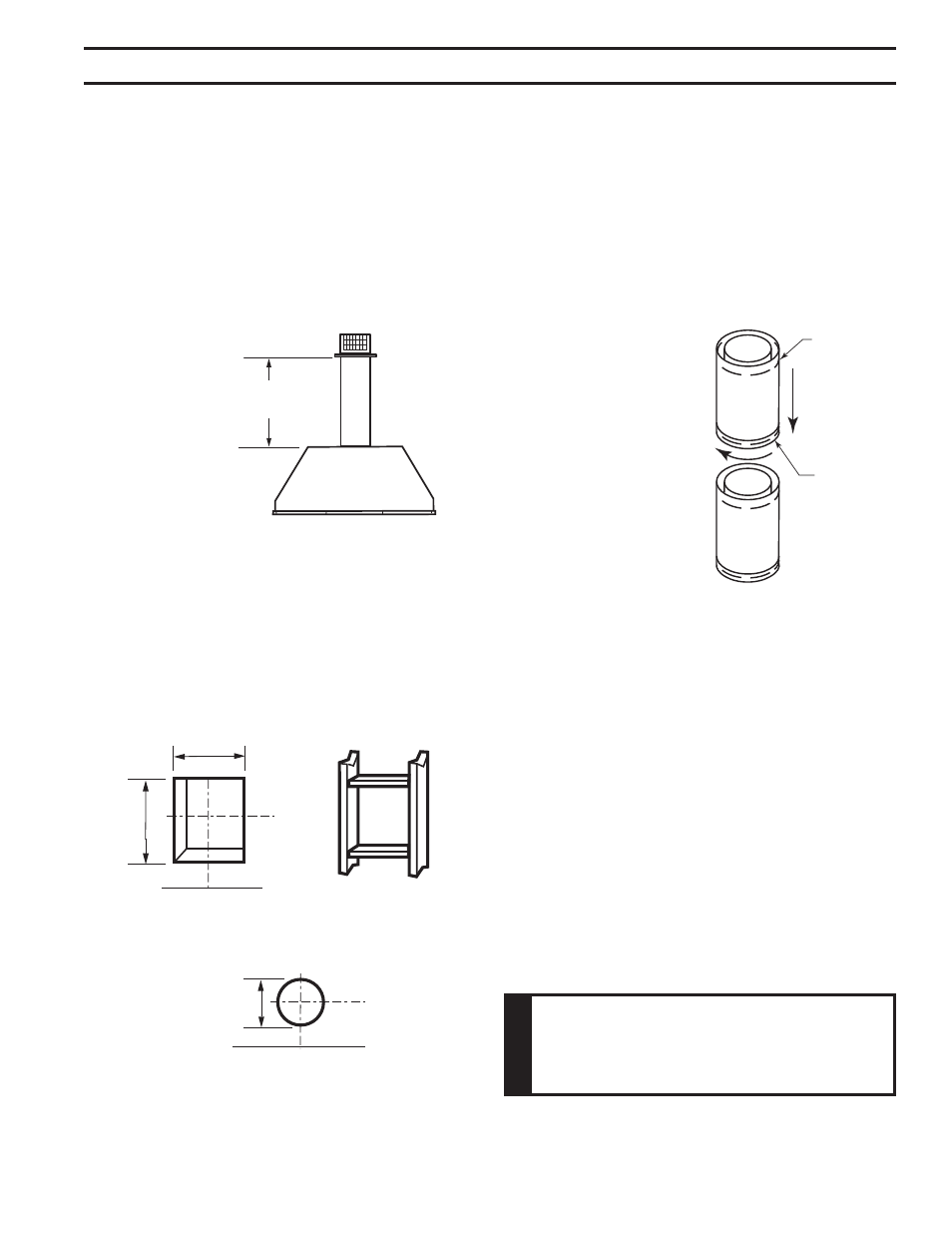

ReAR WALL VeNt INStALLAtIoN

When installed as a rear vent unit this appliance may be

vented directly to a termination located on the rear outside

termination behind the appliance

•

45° elbows may only be attached to rear when used to

direct the flue skyward (to achieve additional rise). Do

not attach 45° elbows to rear of appliance in which the

flue turns either left or right and terminates horizontal.

•

The maximum horizontal distance between the rear

of the appliance and the outside face of the outside

termination is 20" (508 m). Figure 15

DVR584-600

Rear vent no elbows

2/99 djt

Figure 14 -

Rear Vent Application,

Maximum Horizontal Distance

20"(508 mm)

Maximum

DVR584

1. Locate and cut the vent opening in the wall. For com-

bustible walls first frame in opening. Figure 15

combustible Walls: Cut a 11Z\x"H x 9Z\x" W (292 x 24

mm) hole through the exterior wall and frame as shown.

Figure 15

Noncombustible Walls: Hole opening should be 7Z\x"

(190 mm) in diameter.

VO584-100

Vent Opening

2/99 djt

9Z\x"

(241 mm)

11Z\x"

(292 mm)

Vent opening for combustible Walls

Fireplace Hearth

Framing Detail

Vent opening for Noncombustible Wall

7Z\x"

(190 mm)

Fireplace Hearth

VO584-100

Figure 15 -

Locate Vent Opening on Wall

FP1953

rigid pipe

Figure 16 -

Rigid Vent Pipe Connections

Note: horizontal runs of

vent must be supported

every 3' (914 mm). use wall

straps for this purpose.

Female

Locking Lugs

Male Slots

FP1953

2. Rigid vent pipes and fittings have special twist-lock

connections. Assemble the desired combination of pipe

and elbows to the appliance adaptor with pipe seams

oriented towards the wall or floor.

Twist-lock Procedure: The female ends of the pipes

and fittings have three locking lugs (indentations).

These lugs will slide straight into matching slots on

the male end of adjacent pipes and fittings. Push the

pipe sections together and twist one section clockwise

approximately one-quarter turn until the sections are

fully locked. Figure 16

3. Attach vent pipe assembly to the fireplace. Set fireplace

in front of its permanent location to insure minimum

clearances. Mark the wall for a 11Z\x"H x 9Z\x"W (292 x 24

mm) rectangle hole (for noncombustible material such

as masonry block or concrete, a 7Z\x" [190 mm] diameter

hole is acceptable). Figure 15. The center of the hole

should line up with the center line of the horizontal rigid

vent pipe end. Be sure to allow for minimum rise. Cut

a 11Z\x" x 9Z\x" (292 X 241 mm) rectangle hole through

combustible exterior wall (7Z\x" [190 mm] diameter hole

if noncombustible). Frame as necessary. Allow 1/4"

minimum rise per foot. Figure 15

4. Apply a bead of non-hardening mastic around the

outside edge of vent cap. Position the vent cap in the

center of hole on the exterior wall with the word “UP”

on the vent cap facing up. Insure proper clearance of

1" to combustibles is maintained. Attach the vent cap

with four wood screws supplied. Figure 17

Note: Replace the wood screws with appropriate fasteners

for stucco, brick, concrete, or other types of siding.

W

ARNING

Do not recess vent termination into any

wall. this will cause a fire hazard.