Assembly of the touch pad – Matsushita CF-Y5LWVYZ 1 2 User Manual

Page 50

50

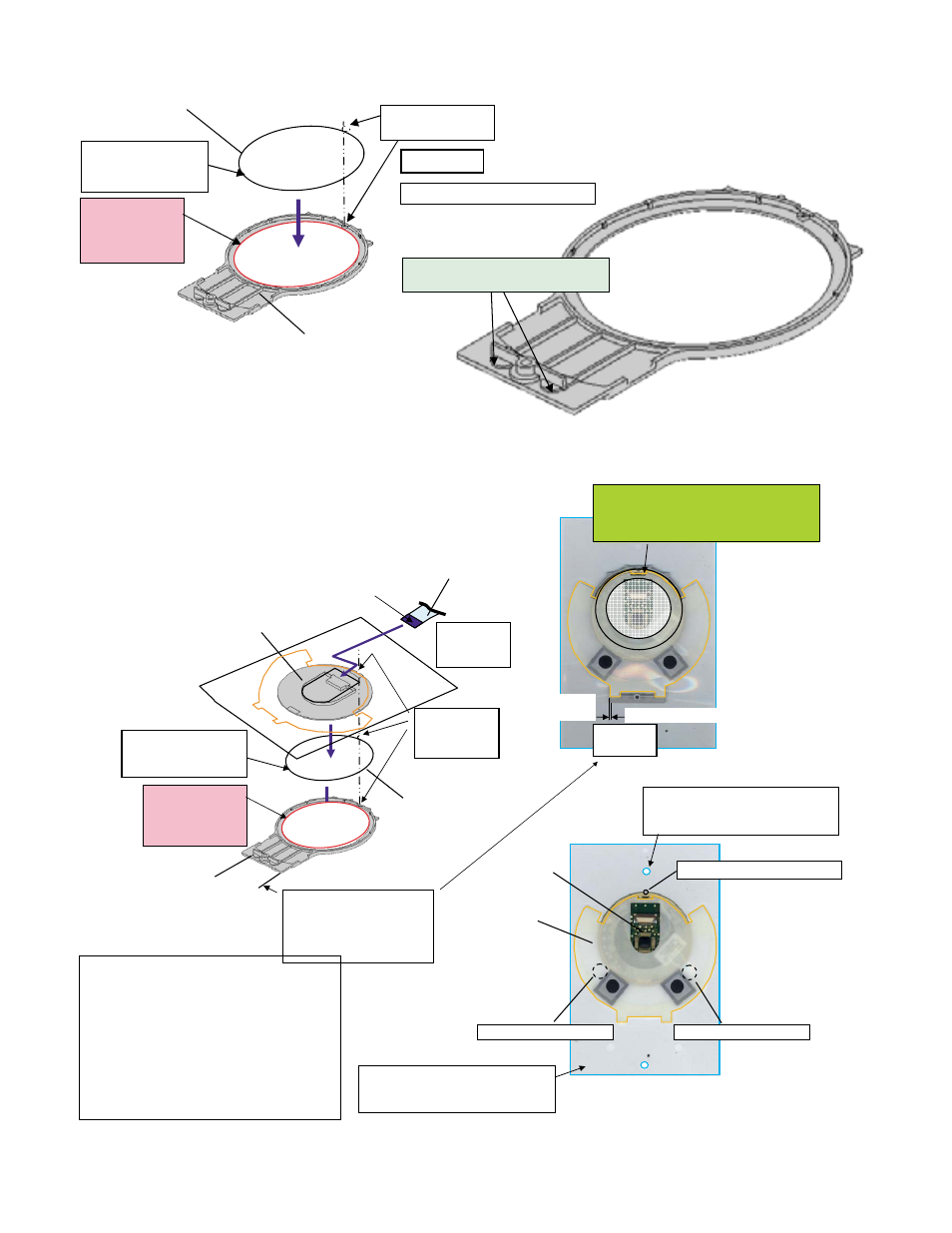

Insertion

after PAD is

pressurized

"NITTO No5000"

Release coated paper

Print side

Touch Pad

Pad WP Sheet

Pad Cover

PAD that has been

prepared is stuck.

Reinforcement board side

Pad FFC is inserted

Thing that doesn’t

begin to be seen

from window of

Pad Cover

Affixes

Pad Cover Tape

It sticks it

according to

U convex part

Sticking

part externals

Pad Cover Externals

The gap is

0.2 or less

After of two PAD preparation completion

It installs in the pressurizing treatment

device and it pressurizes it.

(Range of shaded portion)

The hole of a transparent mount of

PAD WP SHEET is inserted in the

pin of the treatment device.

PAD position-determining pin

PAD positioning spacer

PAD positioning spacer

The hole of a transparent mount of

PAD WP SHEET is inserted in the

pin of the treatment device.

Sticking part externals

and externals match of

Pad Case of sticking PAD

that has been prepared.

1. PAD is installed on the treatment device

and it installs it between positioning

the installation three places.

2.The yellowish brown flaking off paper side

of Pad WS Sheet is peeled off and

the positioning hole of a transparent

mount is inserted in the pin of the

treatment device.

3. The sticking part of PAD and WP Sheet is

pressurized.

9.3.4.5. Assembly of the Touch Pad

Affixes Pad Cover Tape

Pad Cover

Thing that doesn’t

begin to be seen

from window of

Pad Cover

Safety work

Division attention of Pad Cover

"NITTO No5000"

Release coated paper

Print side

It sticks it according

to U convex part.

ZA-0 = It is about the hemicycle.

YA-0 = There is no hemicycle.