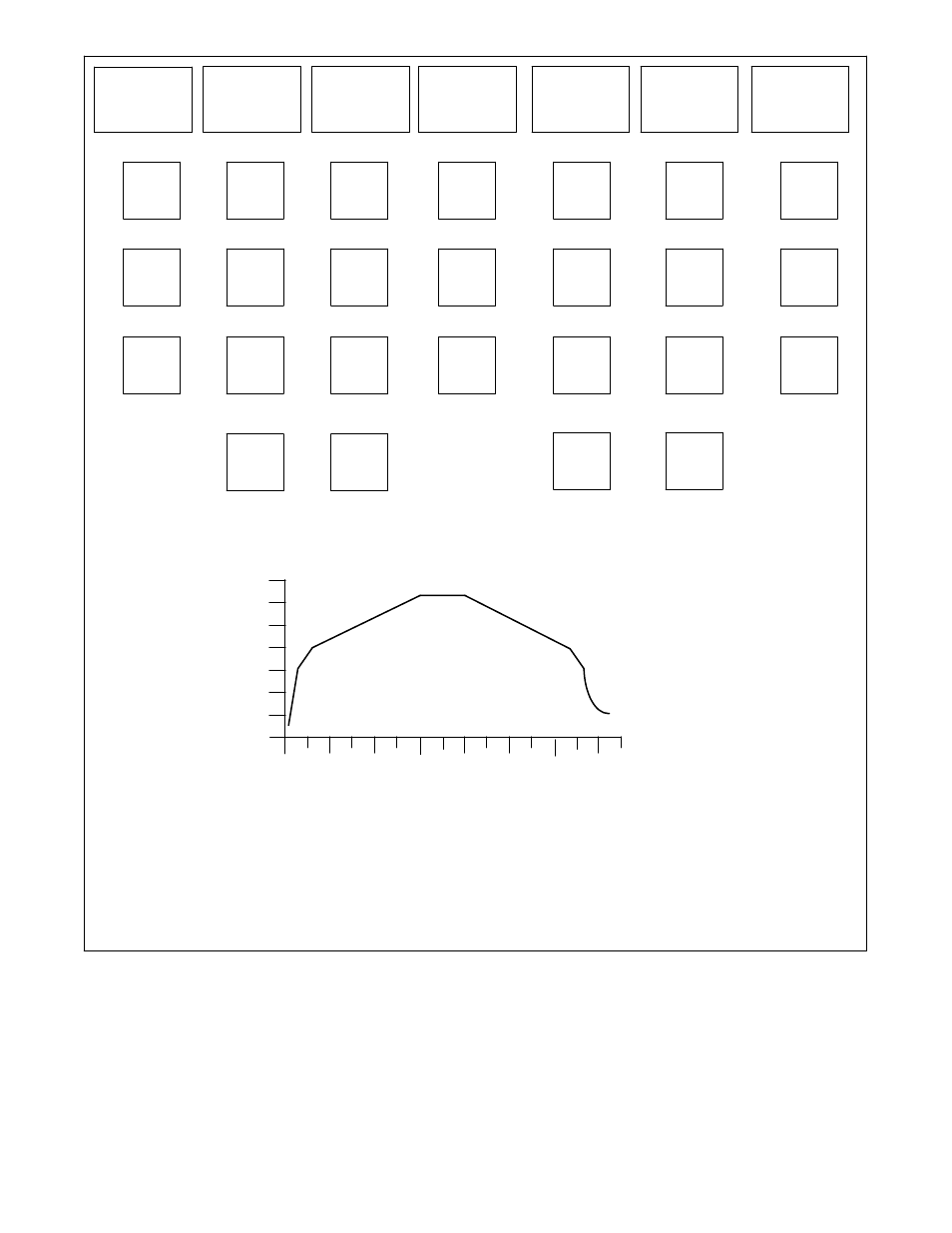

Seg.n 1 type step tgt 600, Seg.n 2 type rmp.r tgt 800, Seg.n 4 type dwel dur 1.0 – Miller Electric IH User Manual

Page 28: Seg.n 5 type rmp.r tgt 800, Rate 400, Rate 200, Seg.n 6 type rmp.r tgt 600, Seg.n 7 type end end.t s op

OM-203 185 Page 24

Step to

600

°

F as

fast as

possible

Ramp to 800

°

F

@ 400

°

/hr

SEG.n

1

tYPE

StEP

tGt

600

(step)

(deg)

SEG.n

2

tYPE

rmP.r

tGt

800

(ramp rate)

SEG.n

4

tYPE

dwEl

dur

1.0

(soak)

(in hrs)

0

200

400

600

800

1000

1200

1400

0.0

1.0

2.0

3.0

4.0

5.0

6.0

Time (hours)

Degrees F

Example Multi−Step Stress Relief Profile

SEG.n

5

tYPE

rmP.r

tGt

800

(ramp rate)

rAtE

400

(deg)

(deg/ hr)

rAtE

200

(deg)

(deg/hr)

Dwell @ 1250

°

F

for 1 hour

Ramp to 1250

°

F

@ 200

°

/hr

7.0

SEG.n

6

tYPE

rmP.r

tGt

600

(ramp rate)

Free fall to

ambient

SEG.n

7

tYPE

End

End.t

S OP

(end)

(sets output to 0)

rAtE

400

(deg)

(deg/hr)

Ramp to 600

°

F

@ 400

°

/hr

Ramp to 800

°

F

@ 200

°

/hr

SEG.n

3

tYPE

rmP.r

tGt

1250

(ramp rate)

rAtE

200

(deg)

(deg/ hr)

.

*On small diameter pipe, it may be necessary to reduce the

output of the power source to achieve a “reasonable rate”

in Segment 1; thereafter, the program controls the rate of

temperature rise and the output power may be increased

to full if desired. To reduce output power, turn power source

output knob to desired setting.

Figure 6-3. Setting A Complex Stress Relief Profile With Multiple Temperature Rise/Cool Rates

Using Example Parameters