3. operation – Miller Electric IH User Manual

Page 23

OM-203 185 Page 19

6-3. Operation

1. Energize IH/TS and power source. A coolant flow error should appear on the IH/TS display. Energize the

cooler and the error will clear from the display.

2. Set up Temperature Profile − per code requirements (see Section 6-3-2 Programming The 2408 Controller).

3. Set up and start Digital Recorder

Digital Recorder (see Section 6-3-3. Batch Recording On The 5100 Digital Recorder)

4. Run the heat process (see Section 6-3-4. Running A Heat Treat and the following tables).

5. Recover from an interruption, if applicable (see Section 6-3-5. Recovering From An Interruption).

6. Retrieve data

Digital Recorder (see Section 6-3-3-4. Batch Recording On The 5100 Digital Recorder)

View and print data (see Section 6-3-6 Review Software).

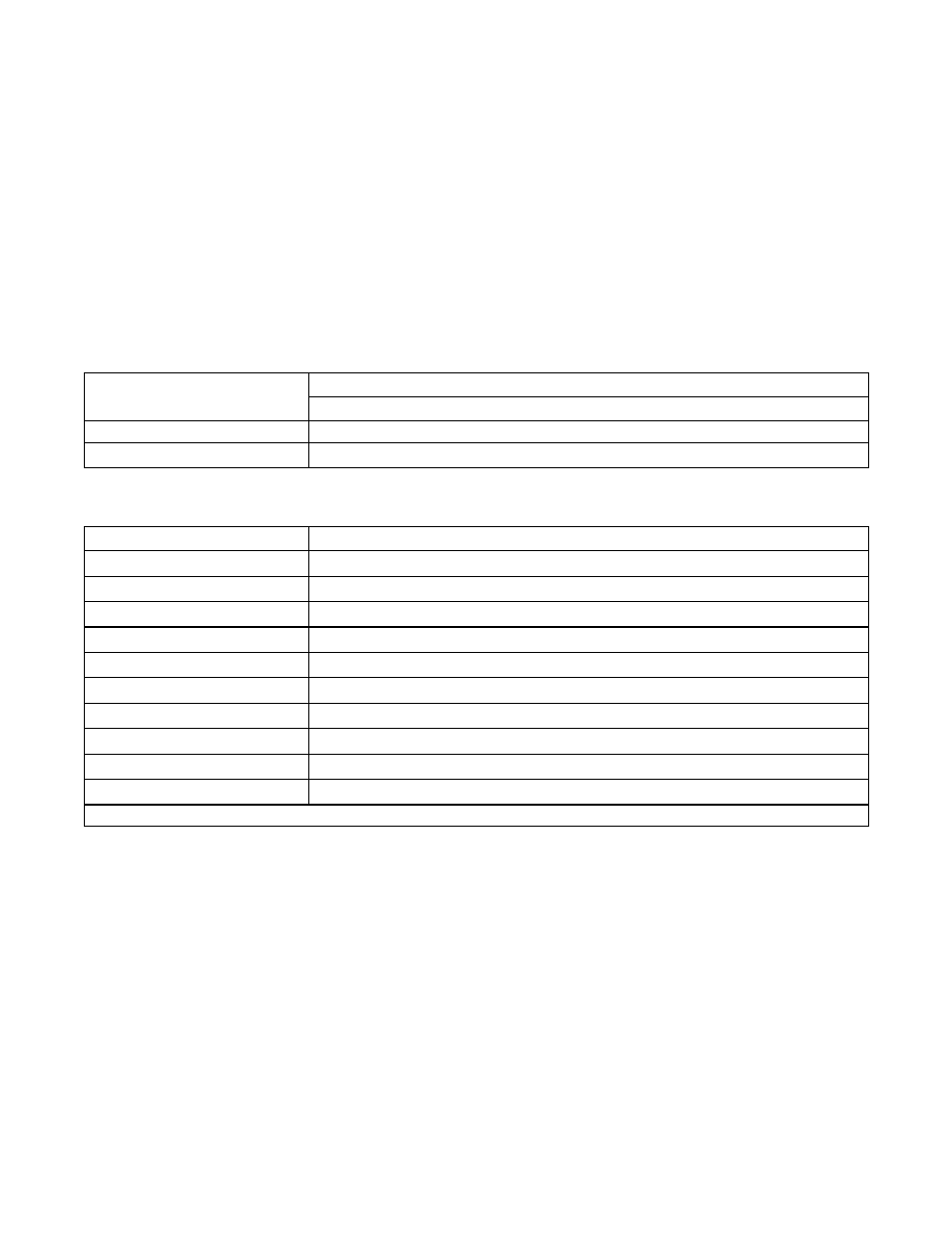

Table 6-1. Controller Display Definitions

Name

Description

Home List (extra parameters may be present.)

Home

Measured value and Setpoint

OP

% Output level

Table 6-2. Run List Sub-Menu Definitions

run

program run List

StAt

Program status (

OFF

,

run

,

hoLd

,

HbAc

,

End

)

PSP

Programmer setpoint

SEG

Active segment number

StyP

Active segment type

SEG.t

Segment time remaining in the segment units

tGt

Target setpoint

rAtE

Ramp rate (if a rate segment)

PrG.t

Program time remaining in hours

SEG.d

*Flash active segment type in the lower readout of the home display (no/YES)

FASt

Runs through program 10 times faster than normal

*This parameter can only be changed when the program is in reset.