5 checking the engine spark plug, 6 clean spark arrestor, 7 cleaning the generator – Guardian Technologies QUIETPACT 40LP 004701-0 User Manual

Page 14

section 3 – Maintenance

recreational vehicle generator

Figure 3.3 – Cleaning Air Intake

USTC

3.5 checkIng the engIne spark

plug

Clean the spark plug and reset the spark plug gap

every 100 hours of operation.

1. Clean the area around the base of the spark plug

to keep dirt and debris out of the engine. Remove

the spark plug and check the condition. Replace

the spark plug if worn or if reuse is question-

able.

2. Clean spark plug by scraping or washing using a

wire brush and commercial solvent. Do not blast

the spark plug to clean.

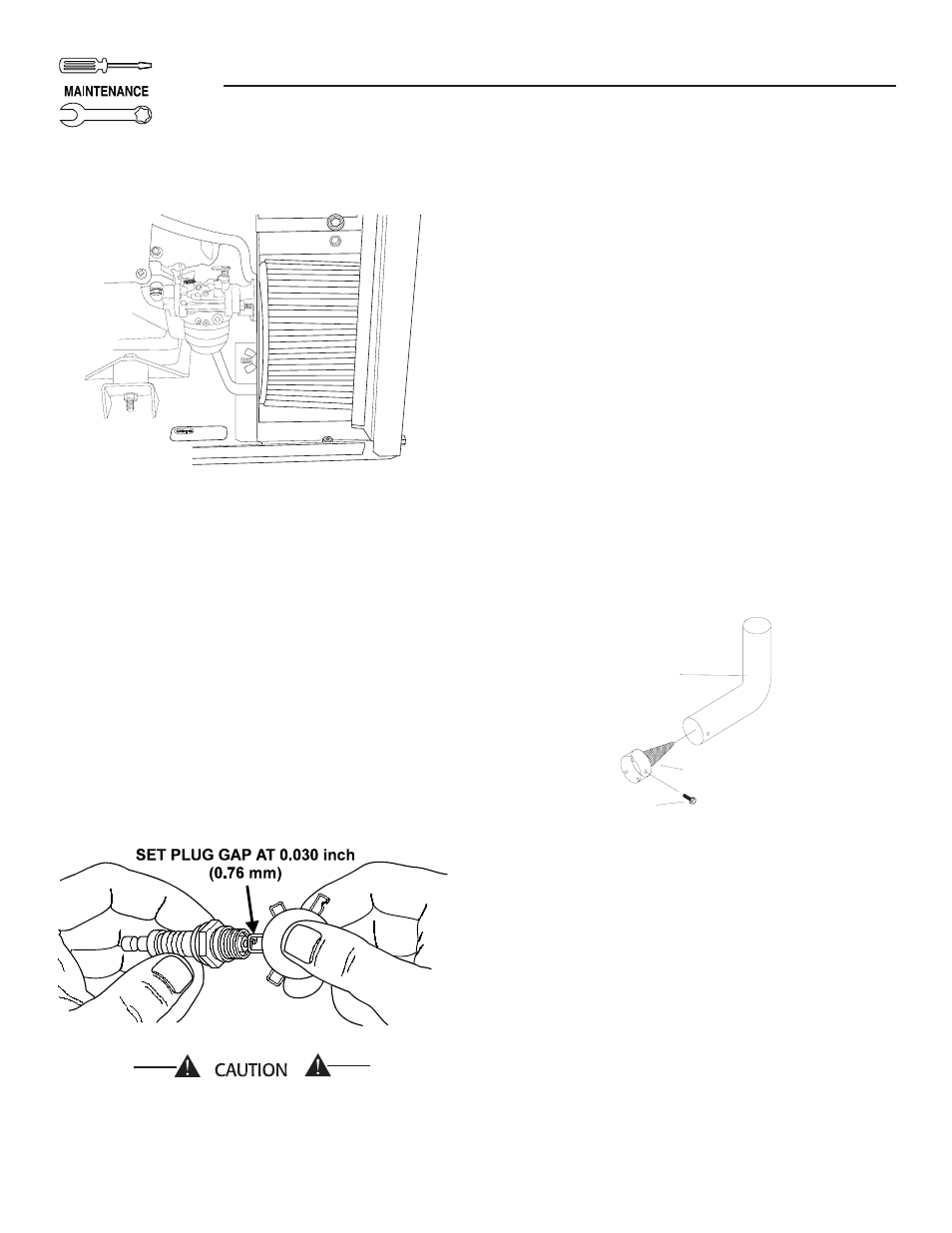

3. Check the spark plug gap using a wire feeler

gauge. Adjust the gap to 0.030 inch (0.76 mm)

by carefully bending the ground electrode

(Figure 3.4).

Figure 3.4 – Setting the Spark Plug Gap

Sparking can occur if the wire terminal does

not fit firmly on the spark plug terminal end. If

necessary, re-form the wire terminal to obtain

a tight fit.

3.6 clean spark arrestor

The engine exhaust muffler has a spark arrestor

screen. Inspect and clean the screen every 50 hours

of operation or once each year, whichever comes first

(Figure 3.5).

NOTE:

If using the generator on any forest-covered,

brush-covered or grass-covered unimproved land,

it must equipped with a spark arrestor. The spark

arrestor must be maintained in good condition by

the owner/operator.

Clean and inspect the spark arrestor as follows:

• Remove the screen retaining bracket by removing

the screw.

• Slide the spark arrestor screen out from the tail

pipe.

• Inspect screen and replace if torn, perforated or

otherwise damaged. DO NOT USE a defective

screen. If screen is not damaged, clean it with com-

mercial solvent.

• Replace the screen and the retaining bracket.

Figure 3.5 - Spark Arrestor

RETAINING

SCREW P/N 056892

SPARK ARRRESTOR

SCREEN P/N 089680

TAILPIPE

P/N 0E0683

3.7 cleanIng the generator

Keep the generator set as clean and dry as possible.

Protect the unit against excessive dust, dirt, corrosive

vapors, road splash, etc. Permitting dirt and mois-

ture to accumulate on generator windings will have

an adverse effect on the insulation resistance of those

windings.

When moisture is allowed to remain in contact with

windings, some of the moisture will be retained in

voids and cracks in the insulation. This causes a

reduced insulation resistance and will eventually

cause problems. Dirt will make the problem worse,

since dirt tends to hold moisture in contact with

windings. Salt (as from sea air) also will worsen the

problem since it tends to absorb moisture from the

air. Salt and moisture, when combined, form a good

electrical conductor which can be damaging to the

generator windings.