1 checking the engine oil level, 2 changing the engine oil and/or oil filter, 3 attention required after submersion – Guardian Technologies QUIETPACT 40LP 004701-0 User Manual

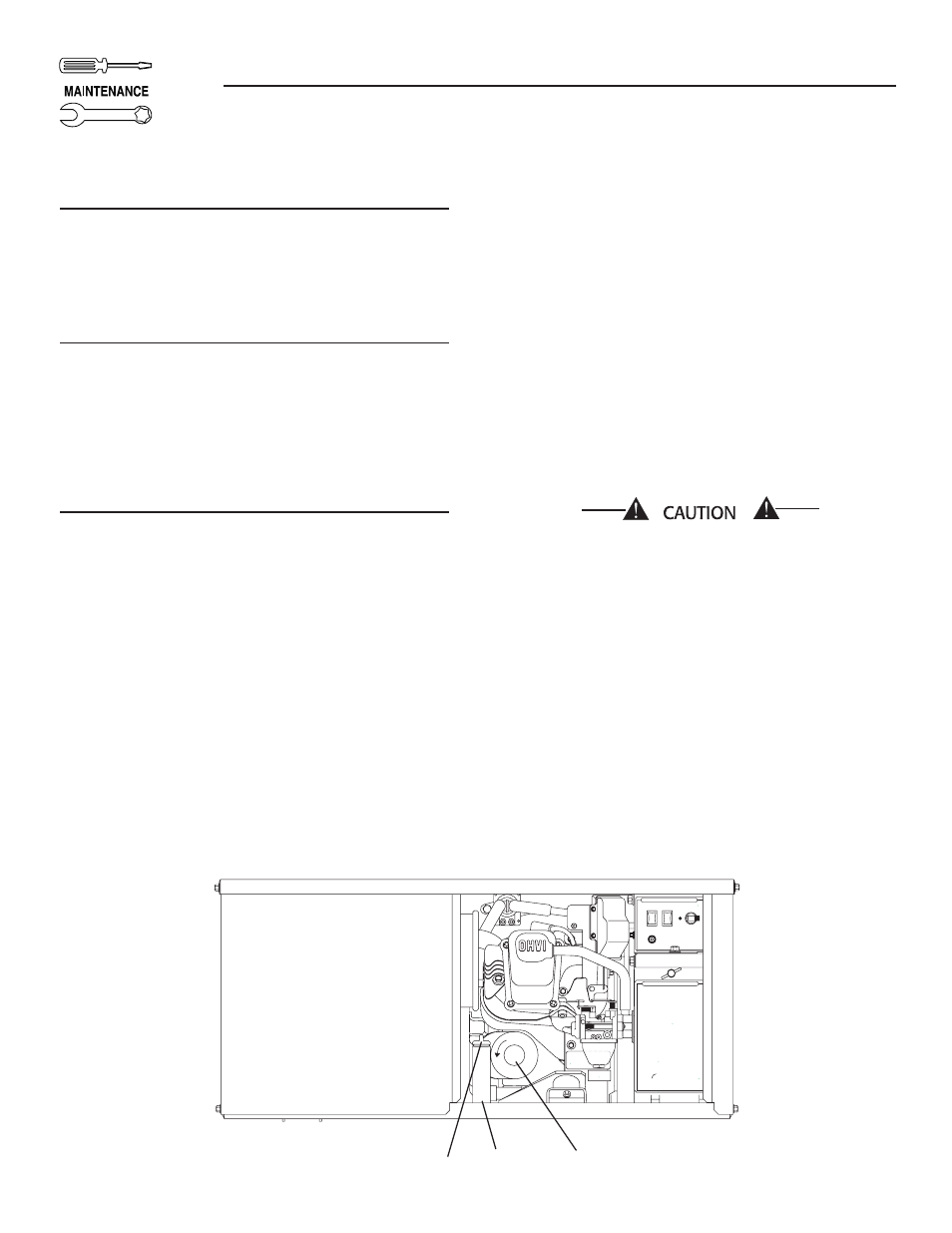

Page 12: 4 operation in high grass orbrush, 5 effects of moisture and dirt, Figure 3.1 – oil maintenance features, Quietpact 0g

0

section 3 – Maintenance

recreational vehicle generator

0

2.9.3 attentIon requIred aFter

subMersIon

If the recreational vehicle generator has been sub-

merged in water, it

MuST NOT be started and oper-

ated. Following any submersion in water, have an

Authorized Service Dealer thoroughly clean and dry

the generator.

2.9.4 operatIon In hIgh grass orbrush

Never operate the generator while the vehicle is

parked over high grass, weeds, brush, leaves or any

other combustible substance. Such materials can

ignite and burn from the heat of the exhaust system.

The generator exhaust system becomes extremely

hot during operation and remains hot for a long time

after it has shut down.

2.9.5 eFFects oF MoIsture and dIrt

Keep the generator set as clean and dry as possible.

Protect the unit against excessive dust, dirt, cor-

rosive vapors, road splash, etc. Permitting dirt and

moisture to accumulate on generator windings will

have an adverse effect on the insulation resistance of

those windings.

When moisture is allowed to remain in contact with

windings, some of the moisture will be retained in

voids and cracks in the insulation. This causes a

reduced insulation resistance and will eventually

cause problems. Dirt will make the problem worse,

since dirt tends to hold moisture in contact with

windings. Salt (as from sea air) also will worsen the

problem since it tends to absorb moisture from the

air. Salt and moisture, when combined, form a good

electrical conductor.

3.1 checkIng the engIne oIl

level

For oil capacities and requirements, see “Engine

Oil Requirements,” Section 1.5.4. Check the engine

crankcase oil level at least every eight hours of opera-

tion, or before using it. To check the engine oil level,

proceed as follows (see Figure 3.1):

1. Be sure the generator is as level as possible.

2. Remove the dipstick and wipe it dry with a clean,

lint-free cloth.

3. Install and tighten the dipstick cap; then, remove

it again. The oil level should be at the dipstick

“Full” mark.

4. If necessary, remove the oil fill cap on the rocker

cover and slowly add oil until it reaches the dip-

stick “Full” mark. DO NOT FILL ABOVE THE

“FULL” MARK.

Never operate the engine with the oil level

below the “Add” mark on the dipstick. Doing

this could damage the engine.

5. Install and tighten the oil fill cap and the dipstick

before operating the engine.

3.2 changIng the engIne oIl

and/or oIl FIlter

• Change the

engine oil after the first 25 hours

of operation (after the 25-hour break-in peri-

od, see Section 2.10.1). Thereafter, change the

oil every 100 operating hours. Change the oil more

frequently if operating consistently under heavy

load or at high ambient temperatures.

GENERAC OHVI INDUSTRIAL ENGINE

I

t

r

e ,

e

h it

w a

n c .-

s

m

, I

e

W

POWERED

W

y s

S

r

o

P

w e

A C

N

R

E

G E

OHVI

t

GENERAC

TM

RV SERVICE LOCATOR:

.00..

QUIETPACT 0G

*

S E R V IC E A C C E S S

P A N E L

OIL LEVEL:

CHECK DAILY

AIR FILTER:

CLEAN PREFILTER

EVERY 100 HOURS.

REPLACE ELEMENT

EVERY 250 HOURS.

OIL & OIL FILTER:

CHANGE EVERY 100

(IF NECESSARY)

EVERY 500 HOURS.

HOURS. REPLACE PLUGS

PLUGS EVERY 100

INSPECT & CLEAN

SPARK PLUGS:

REPLACEMENT INFORMATION

*

PERFORM MORE OFTEN IN DUSTY CONDITIONS

AIR FILTER LOCATED BEHIND PANEL.

MAINTENANCE SCHEDULE

AIR FILTER P/N:

0D3262

070185

OIL FILTER P/N:

SPARK PLUG P/N:

072347

OIL CAPACITY WITH FILTER:

0.8L/0.84QT

TEMPERATURE

SAE VISCOSITY

32˚F AND HIGHER

10˚F TO 100˚F

0˚F TO 80˚F

-20˚F TO 50˚F

5W-30

10W-30

15W-40

30

WHEN SERVICE OR PARTS ARE NEEDED IN

THE USA OR CANADA, CONTACT THE GENERAC

SERVICE LOCATOR AT 1-800-333-1322.

HOURS. (OR ANNUALLY)

PREFILTER P/N:

0D4511

FUEL FILTER P/N:

0D7515

FUEL FILTER:

CHANGE EVERY 400

HOURS. (OR ANNUALLY)

*

*

P R I M E

F U E L

S T O P

S T A R T

3 0 A

C . B .

A

F U S E

CONTROL CENTER

7.5

To Rem

ov

e

Oil Dipstick/Oil Fill

Oil Drain

Oil Filter

Figure 3.1 – Oil Maintenance Features