Installation, 4 electrical cartridge securing, 5 electrical connections - testing – Glow-worm Ultracom hxi User Manual

Page 23: Commissioning, 1 preliminaries - all systems, 2 filling the heating circuit, 3 gas supply

0020107233_00 - 06/11 - Glow-worm

INSTALLATION

- 23 -

9.4 electrical Cartridge Securing

Close the cartridge and secure with the previously removed

screw.

Push the electrical cartridge into the interface housing on

completion of the wiring, see diagram 9.3.

Secure with the two cartridge retaining screws provided in the

cartridge body.

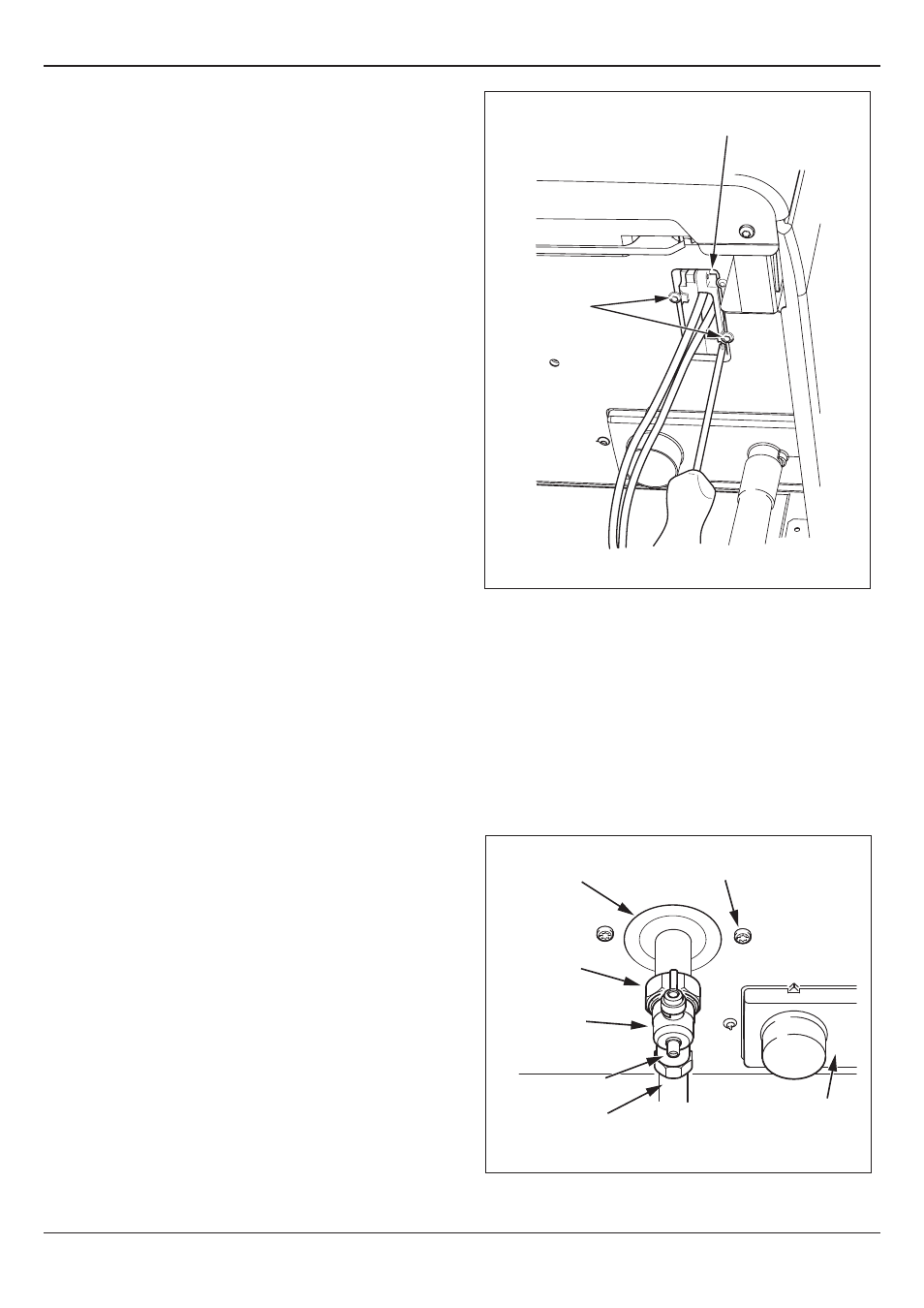

9.5 electrical Connections - Testing

Carry out preliminary electrical system checks as below:

1. Test insulation resistance to earth of mains cables.

2. Test the earth continuity and short circuit of cables.

3. Test the polarity of the mains.

noTe: If you require to test the appliance refer to section 12.

13301

Diagram 9.3

ELECTRICAL

CARTRIDGE

FIXING

SCREWS

Commissioning

IMPoRTanT: At the time of commissioning, complete all

relevant sections of the Benchmark Checklist located in the

inside back pages of this document.

10.1 Preliminaries - all Systems

The commissioning should be carried out by a

competent

person approved at the time by the Health and Safety

Executive and in accordance with the current issue of

BS6798.

Do noT operate the boiler without water.

Make sure that the system has been thoroughly flushed

out with cold water and that all cleanser, if used, has been

removed.

Isolate the boiler from the mains electrical supply.

Test for gas tightness and purge air from the gas supply.

IMPoRTanT: Before starting the boiler check that all flue

connections are secure and sealed correctly.

10.2 filling the Heating Circuit

With the gas isolation valve closed and with no demand from

any external controls.

1. Fill the heating system.

Sealed system only - fill the system to a pressure of 1.0bar.

2. Vent all air from the system - repeat as necessary until the

system is full and all the air has been vented.

10.3 Gas Supply

The gas valve is factory set for natural gas (G20) and should

need no adjustment. Turn on the gas supply at the isolation

valve, see diagram 10.1. Check the supply pressure at the

pressure test point is 20mbar.

15704

Diagram 10.1

GAS

SUPPLY PIPE IN

GAS PIPE BRACKET

SECURING SCREW

GAS

SERVICE

ISOLATION

VALVE

UNION

NUT

SEALING

GROMMET

CONDENSE TRAP

& SIPHONIC DRAIN

PRESSURE TEST

POINT