Installation, 9 combined feed and vent, 10 sealed water systems – Glow-worm Ultracom hxi User Manual

Page 16: 11 safety valve, 12 expansion vessel, 13 pressure gauge, 14 water makeup, 15 filling a sealed water system

0020107233_00 - 06/11 - Glow-worm

INSTALLATION

- 16 -

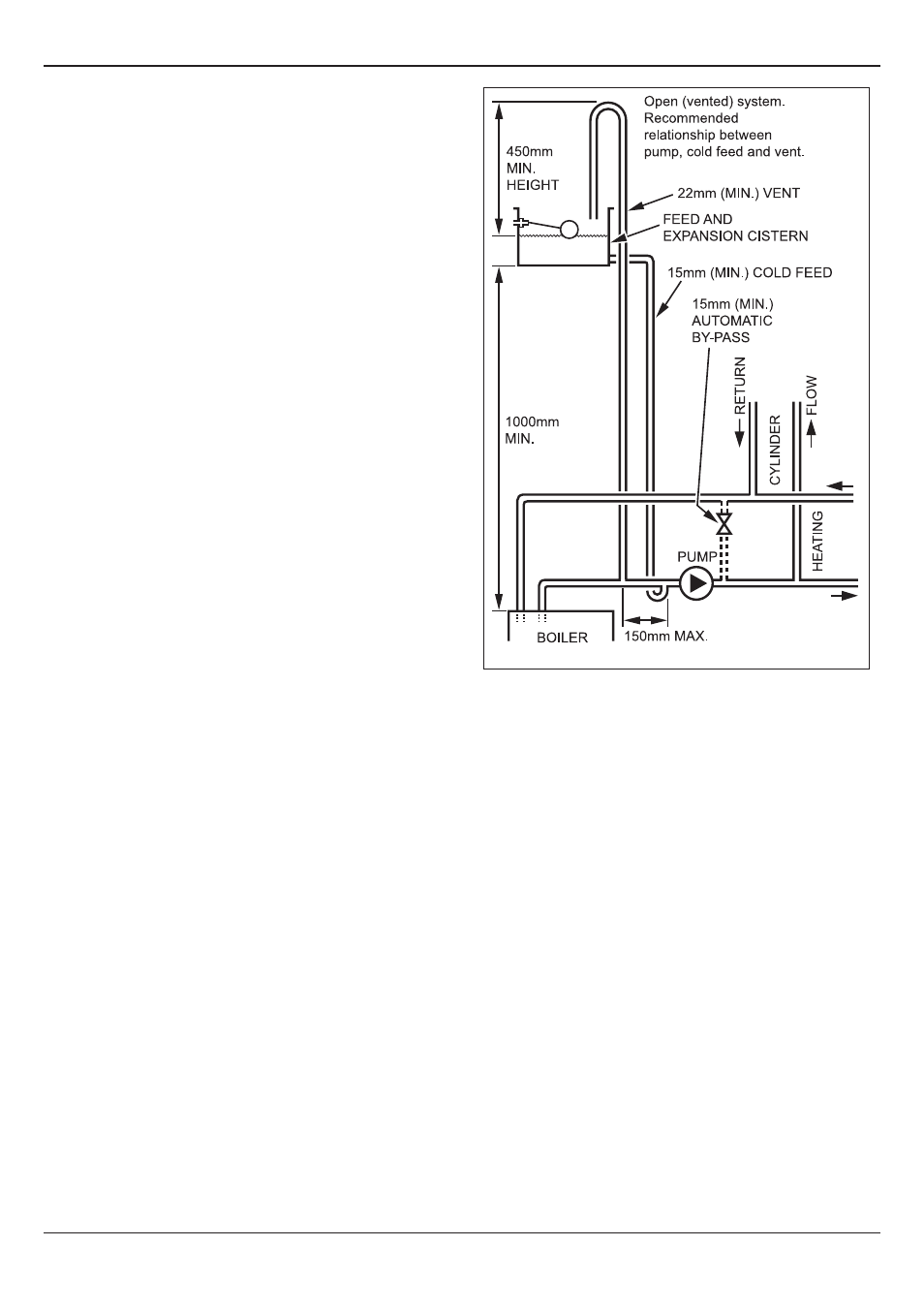

Water System - open (Vented) Central

Heating System

The boiler must be supplied from an unrestricted water

supply taken from a feed and expansion cistern situated at a

maximum height of 27 metres (90ft) above the boiler.

The cold feed must be 15mm minimum size.

The vent must rise continuously and be unrestricted.

It is important that the relative positions of the pump, cold feed

and open vent are as shown in diagram 5.2.

5.9 Combined feed and Vent

For combined feed and vent, a 22mm pipe must be fitted in

accordance with BS 5449.

5.10 Sealed water Systems

The installation must comply with the appropriate

requirements of the current issue of BS4814, BS5449,

BS6759, BS6798 and BS7074 Part 1 and 2.

See diagram 5.3 for a suggested layout.

5.11 Safety Valve

A safety valve must be fitted to a sealed system. It shall

be preset, non-adjustable with a lift pressure of 3 bar,

incorporating seating of a resilient material, a test device and

a connection for drain.

The drain from the safety valve must be routed outside the

building, must not discharge above an entrance or window

or any type of public access area, be clear of any electrical

fittings and positioned so that any discharge can be seen.

5.12 expansion Vessel

A diaphragm type expansion vessel, conforming to the current

issue of BS4814 (see also BS7074 Part 1 and 2) must be

connected at a point close to the inlet side of the circulating

pump, see the diagrammatic layout, diagram 5.3 unless laid

down differently by the manufacturer.

The expansion vessel volume depends on the total water

system volume and the initial system design pressure. For

any system an accurate calculation of vessel size is given in

the current issue of BS5449 and BS7074 Part 1.

Example: For an initial design pressure of 0.7 bar, the

minimum total vessel volume required is 0.063 x Total System

Volume.

noTe: A higher initial design pressure requires a larger

volume expansion vessel.

In GB, guidance on vessel sizing is also given in the current

issue of BS5449 and BS7074 Part 1.

In IE refer to the current edition of I.S.813 “Domestic Gas

Installations”.

The charge pressure must not be less than the static head

of the system, that is, the height of the highest point of the

system above the expansion vessel.

5.13 Pressure Gauge

A pressure gauge with a set pointer and covering at least 0 to

4 bar (0 to 60 lb/in2) shall be fitted permanently to the system

in a position where it can be seen when filling the system.

Diagram 5.2

13147

5.14 Water Makeup

Provision should be made for replacing water loss from the

system using a make up bottle mounted in a position higher

than the top point of the system, connected through a non-

return valve to the return side of either the heating circuit or

the hot water cylinder. Alternatively, provision for make up can

be made using a filling loop.

5.15 filling a Sealed Water System

Provision for filling the system at low level must be made, see

diagram 5.4. There must be no permanent connection to the

mains water supply, even through a non-return valve.