Chapter 3 functional description, 1 introduction, 2 mechanical description – AERCO SWDW68 U-Tube Double-Wall Heaters w/ECS User Manual

Page 21: 1 overview, 2 mechanical description 3.2.1 overview

Rev B Mar 2013

3-1

CHAPTER 3 FUNCTIONAL DESCRIPTION

3.1 INTRODUCTION

The AERCO DW-series steam-to-water heat exchangers incorporate double–wall heat tubes, in which

steam circulating in a bundle of immersed double-wall primary tubes heats the service water in the heat

exchanger’s shell. The following Mechanical Description (3.2) briefly discusses how double-wall heat

tubes work and describes each of the principal steam-to-water heat exchanger components. The

Mechanical Description is followed by a discussion of the Electronic Control System (3.3), which regulates

the heat exchanger water temperature and activates alarms and shutdown processes in the event safety

limits are exceeded.

3.2 MECHANICAL DESCRIPTION

3.2.1 Overview

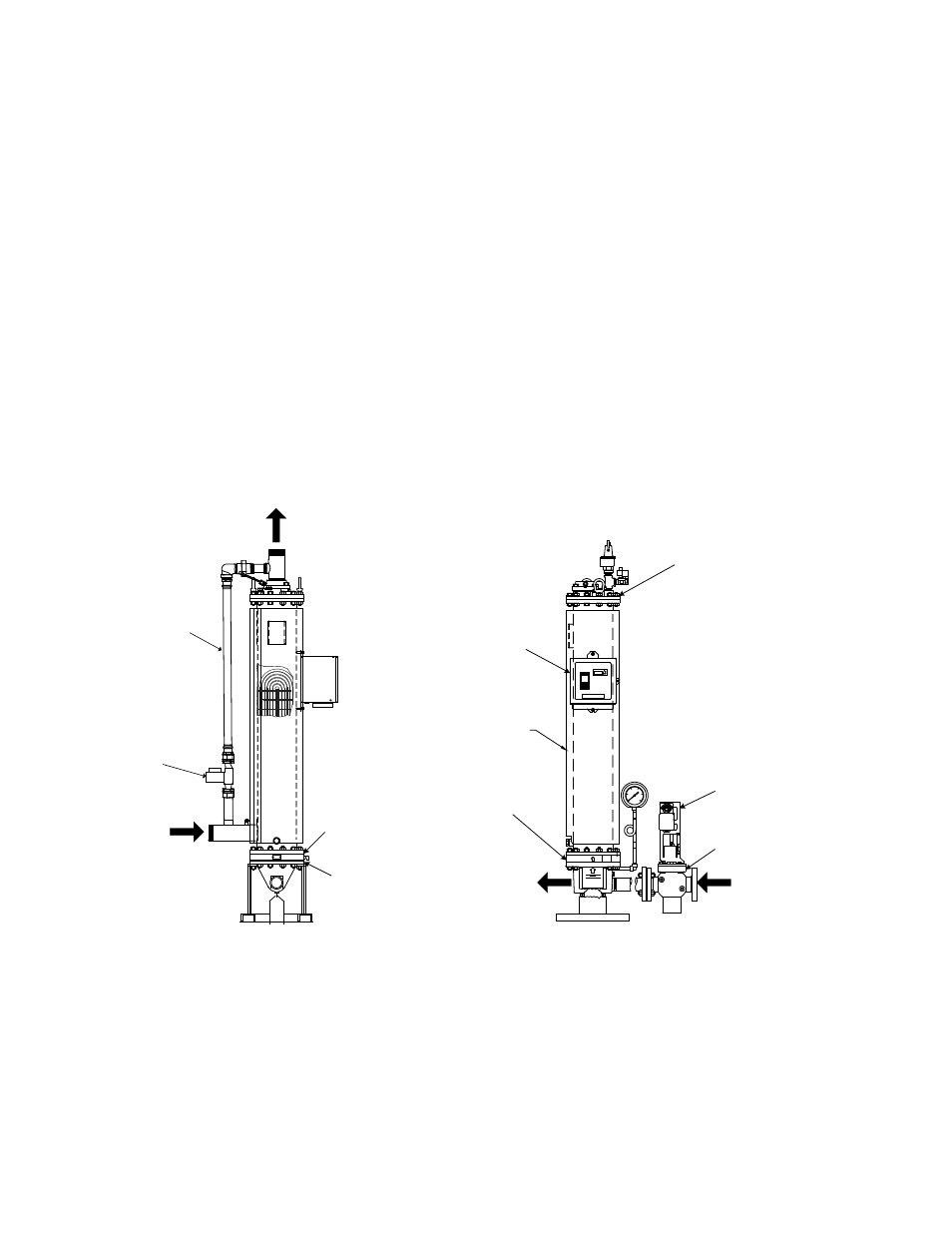

Referring to Figure 3-1, cold service water entering the heat exchanger through the Cold Water Input is

dispersed evenly throughout the heat exchanger shell. As the cold water flows upward, it is heated by

steam circulating through the immersed tube bundle. The heated service water exits through the Hot

Water Output connection in the upper head assembly.

AERCO

STEAM INPUT

CONDENSATE

OUTPUT

SHELL

COLD WATER

INPUT

HOT WATER OUTPUT

CONTROL BOX

RECIRCULATION

PIPING

RECIRULCATION

PUMP

UPPER HEAD ASSEMBLY

CXT-E CONTROL

VALVE

CXT-E ACTUATOR

LOWER HEAD

ASSEMBLY

UPPER

TUBESHEET

LOWER

TUBESHEET

Figure 3-1. AERCO Steam-to-Water Double-Wall Heat Exchanger

The heating steam enters through the CXT-E Control Valve at the bottom of the heat exchanger

assembly and flows through the inner tubes of the double-wall tube bundle. The flowing steam transfers

its heat to the service water contained within the shell, condenses and exits through the Condensate

Output connection.

The flow rate of the heated water varies according to the demand for hot water. The flow rate of the

steam is regulated by the Temperature Controller in the Control Box so as to maintain the temperature of