Operation, Vacuum system – Prochem Legend XL User Manual

Page 20

OPERATION

86037400 02/16/07

3-10

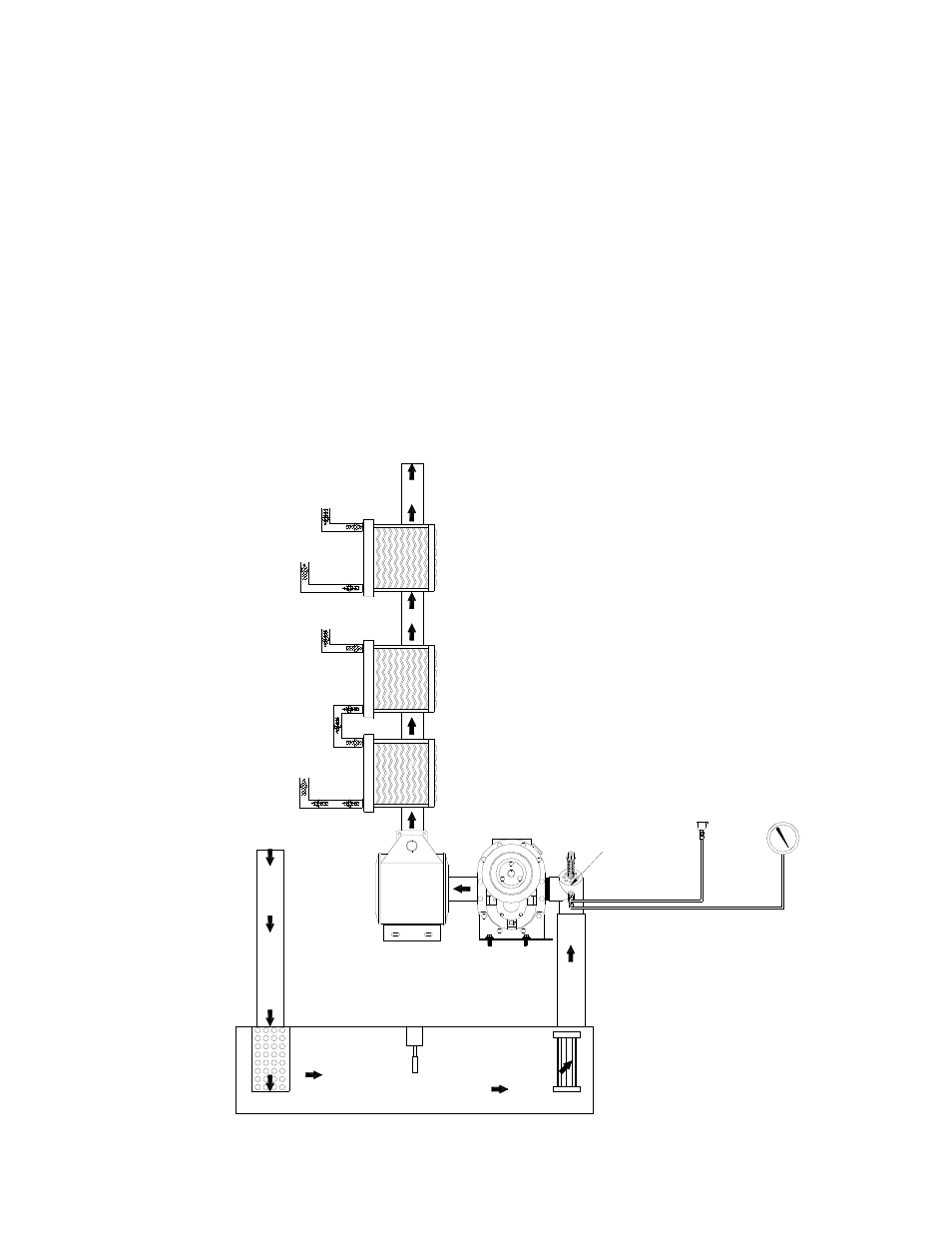

VACUUM

GAUGE

LUBRICATION

CUP

VACUUM

BLOWER

VACUUM

SILENCER

VACUUM

RELIEF

VALVE

FROM PRESSURE

REGULATOR

VACUUM EXHAUST

"RADIATOR TYPE"

STAINLESS STEEL

HEAT EXCHANGER

TO

SOLUTION OUTLET

TO WATER BOX

LEVEL SENSOR

(ENGINE SHUT-OFF SWITCH)

FILTERS

VACUUM EXHAUST

OUTLET

VACUUM EXHAUST

"RADIATOR TYPE"

COPPER

HEAT EXCHANGER

VACUUM EXHAUST

"RADIATOR TYPE"

STAINLESS STEEL

HEAT EXCHANGER

VACUUM

INLET

STRAINER

FROM PRESSURE

REGULATOR

WASTE TANK

VACUUM SYSTEM

The engine turning an air pump generates vacuum.

The air is channeled in one side of the vacuum

pump, compressed and discharged on the opposite

side, creating airflow.

The movement of air is used to do the work

necessary for the extraction process. A vacuum

nozzle applied to the carpet surface removes

moisture, dirt and spent chemicals. These elements

are conveyed back to a separating tank utilizing

hoses and the force of air. Particles of moisture and

dirt are separated in the vacuum tank using a series

of changes in direction and velocity. The air is then

filtered and rushes into the vacuum pump.

The vacuum pump compresses and heats the

incoming air. The hot discharged air is forced down

stream into a silencer for noise abatement. After

exiting the silencer, this hot air is mixed with the hot

air and gases from the engine. This mixture of hot

air and gases are then forced through 3 radiators

serving as heat collectors. Heat from the engine

and vacuum pump is then transferred into the

plumbing system raising the water temperature for

better cleaning.

The engine and blower speeds are factory set to

maximize vacuum pressure and provide sustained

system life. Do not alter the engine or vacuum

speeds outside the recommended ranges shown in

the Technical Specifications section.