INOR PROFIPAQ-L User Manual

Page 12

12

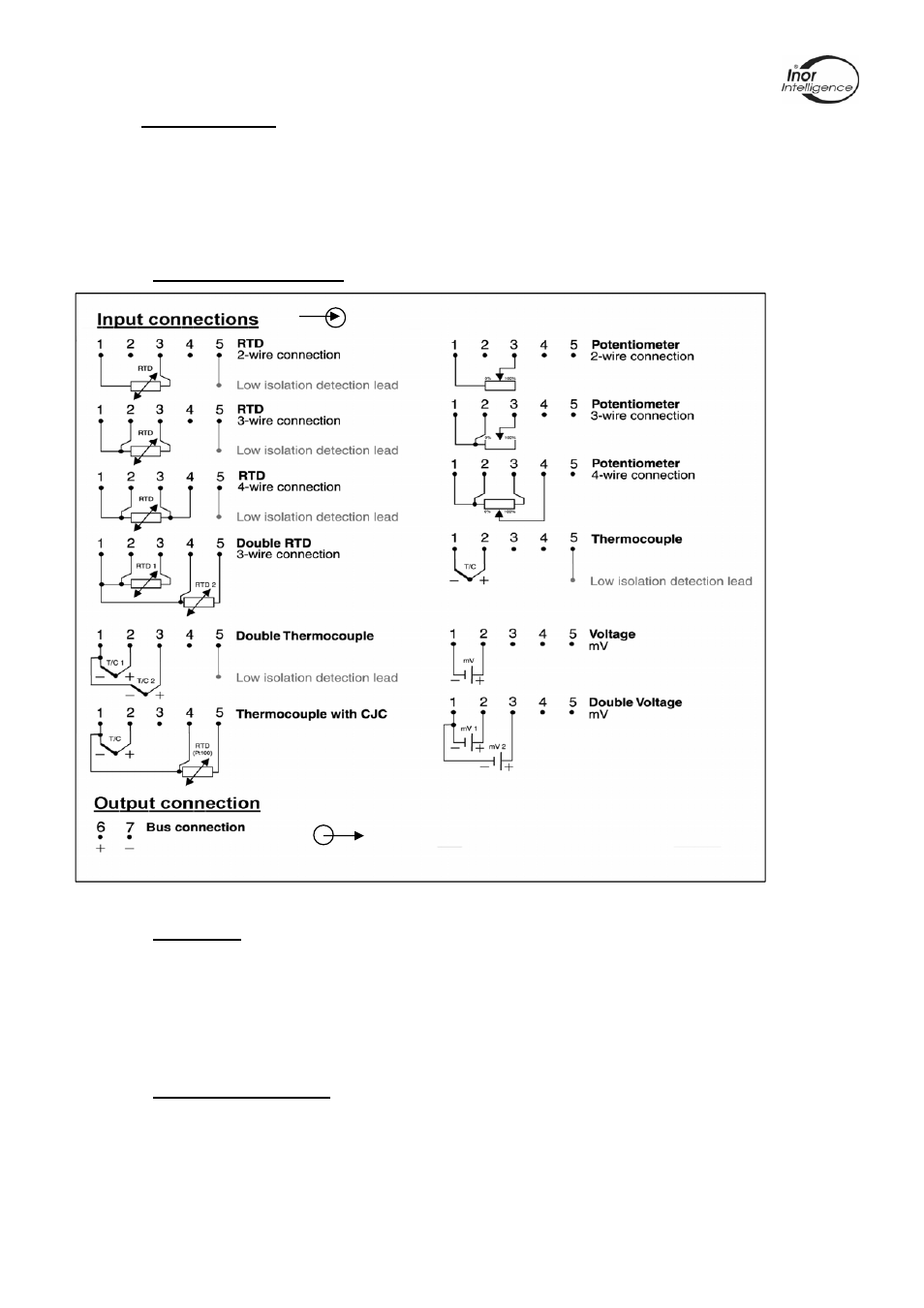

2.6 Connections

The input and output/power supply of the ProfIPAQ are connected according to

connection chart, Figure 12. The output connection (Bus connection) is polarity

independent. Also see Appendix B, Profibus cabling.

To ensure an adequate sensor connection, anchor the sensor lead wires beneath the flat

washer on the terminal screw.

2.6.1 Connection Diagram

Figure 12 Connection chart

2.6.2 LCD-W12

A special LCD-indicator, INOR LCD-W12, can be connected to the communication port of

the ProfIPAQ. It gets its power and digital data from the ProfIPAQ. The activation of the

communication port as a display connection and number of decimals to be shown in the

display are selected via the ProfiSoft software, see chapter 4. The display LCD-W12 is not

approved for mounting into Ex Hazardous area.

2.6.3 Ex Bus connection:

The models ProfIPAQ-HX and ProfIPAQ-HX/Dxy must be electrically connected via a

certified intrinsic safe power supply unit or an intrinsic safe segment coupler, which is

mounted outside the hazardous area, for use in Ex ia or Ex ib applications. For non-

incendive Ex nL applications (ProfIPAQ-H and ProfIPAQ-H/Dxy) the transmitter must be

connected to a standard power supply (Class 2 for USA). Provisions shall be made to protect

the transmitter from transient disturbances of more than 42V on power supply lines.