GxT Ferret 92 Color Labscope User Manual

Page 21

21

www.gxtauto.com

Port Fuel Injector:

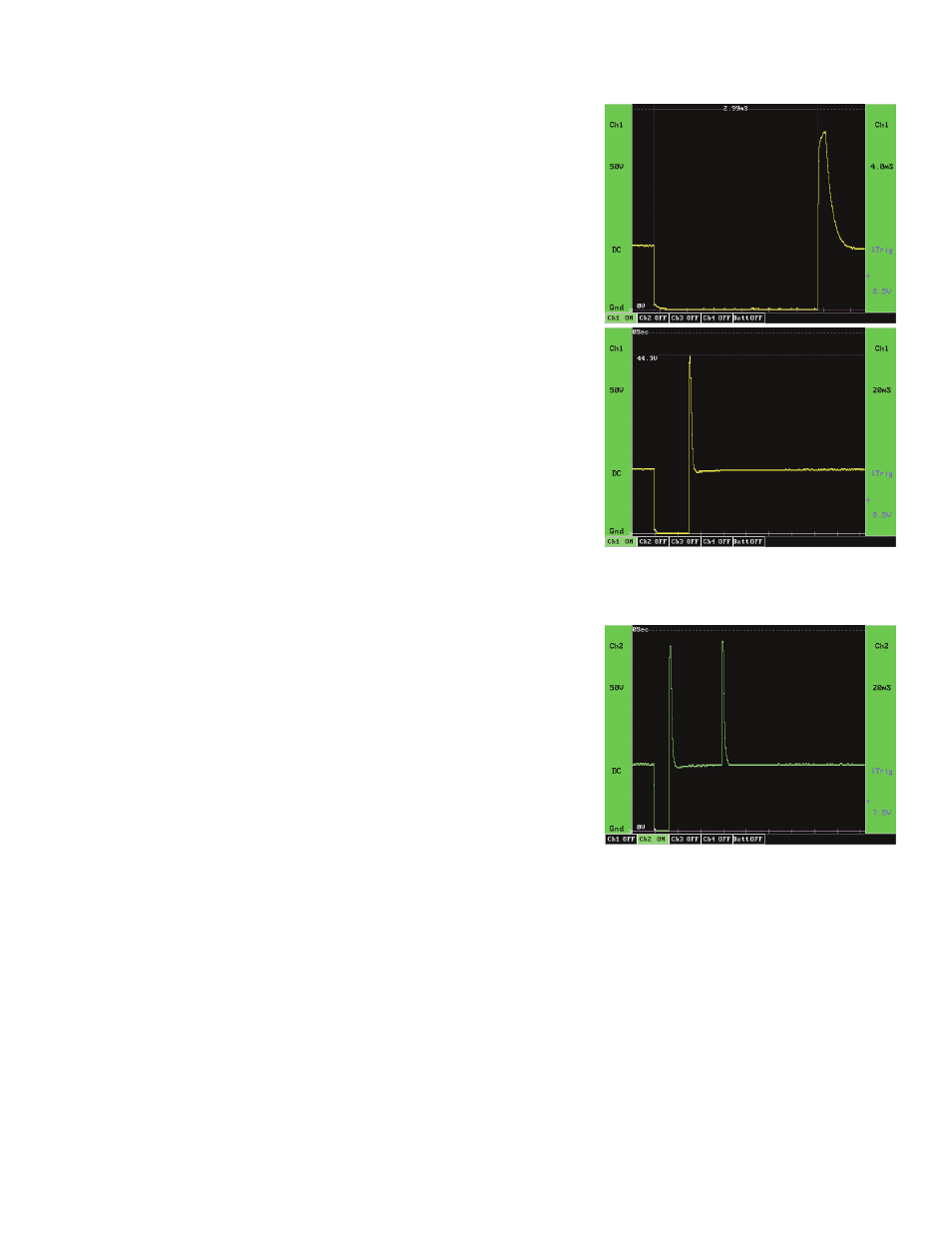

Fig. 16 is a capture of a typical saturated switch fuel injector. It is a

high speed digital signal and is not viewable in real time. As you can

see the relatively short Time Base and ground at the bottom gives

maximum resolution. Time cursors were used to measure the pulse

width at 2.99mS.

Fig. 17 is a capture of the same injector as Fig. 16, but with a much

longer Time Base allowing plenty of room for change in pulse width if

we decide to snap the throttle to watch the system respond. As you

can see, a Voltage Scale of 50 volts was used here, allowing us to see

the voltage spike at 44.3 volts amplitude.

This injector has power to one side of the winding when the ignition is

turned on and the driver completes the ground side of the circuit to

pulse it. The proper way to connect your scope leads here is negative

to a good ground and positive to the control, or negative, side of the

injector. We used a negative slope trigger because the driver pulls the

control side of the circuit to ground to pulse the injector. This means

that voltage will decrease when the injector is pulsed. Trigger level

is set fairly close to the middle of this voltage transition. If excessive

resistance is present in the control side of the circuit, voltage may not

be pulled to ground. If trigger level was set too low the voltage level

might not fall past the set level, in which case, the scope would not

trigger.

Peak & Hold Injector:

Fig. 18 is a peak and hold injector. We have our scope leads hooked

up the same as we did in Fig. 17 and used similar settings. You can

see that the waveform for this injector is different than the saturated

switch injector we just looked at. it has two voltage spikes. This type

of injector is used on CFI and TBI systems where it must open much

more often that port fuel injectors. Because of this it must open faster,

so it has a very low resistance winding. If it were controlled the same

as a port injector the high current draw would produce a lot of heat

which would cause the driver to fail. To overcome this obstacle two

drivers are used, One driver switches the circuit to ground to snap the

injector open and shuts off after a very short time, a little over 1 mS.

This gives the driver plenty of time to cool down, The second driver

completes the circuit through a resistor, reducing the current to only

what is needed to hold the injector open for the remainder of its on time.

The fi rst voltage spike occurs when the peak driver circuit is opened

and the second when the hold driver is opened.