Heath Zenith SL-5309 User Manual

Page 2

2

595-5496-06

W

IRE

THE

L

IGHT

C

ONTROL

.

❒

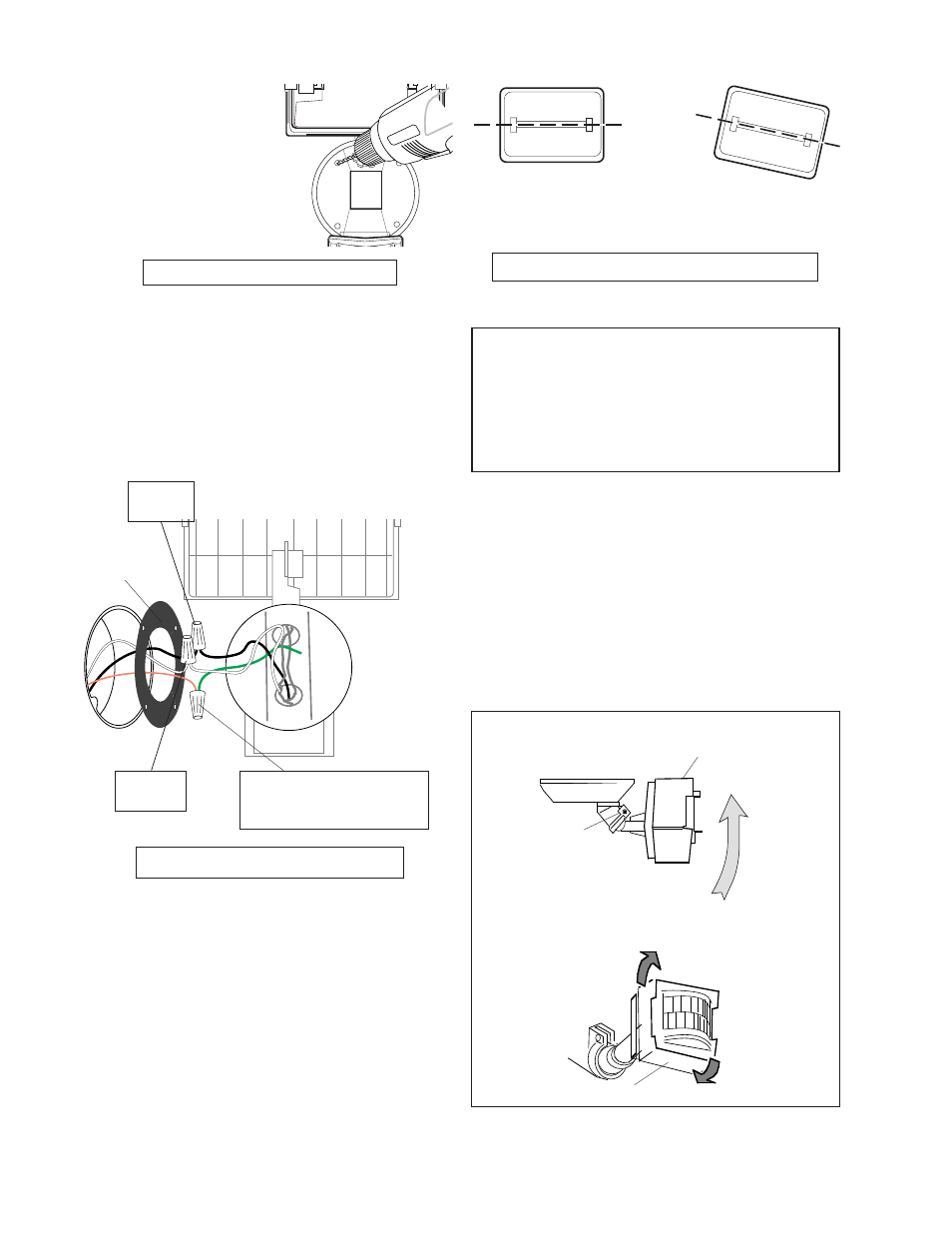

Turn the power to the lighting circuit off at the

fuse or circuit breaker box.

❒

Remove the existing light fixture.

❒

Strip about 5/8" (16 mm) insulation from the exist-

ing junction box wiring.

❒

Route the Light Control’s wires through the large

hole in the gasket.

❒

Twist the junction box wires and fixture wires to-

gether as shown. Secure with a wire connector.

For proper operation and safety, the light fixture

must be above the sensor.

❒

Align the Light Control cover plate and cover plate

gasket and the junction box. Insert and tighten the

mounting screws.

❒

If not installed on a weatherproof box or if an

adaptor plate is used, caulk the wall plate and

mounting surface with silicone weather sealant.

M

OUNT

THE

L

IGHT

C

ONTROL

.

Cover

Plate

Gasket

The halogen light must be

mounted horizontally (+/- 4

°

).

RIGHT

WRONG

B

ULB

I

NSTALLATION

A

ND

R

ELAMPING

.

❒

When re-lamping, turn power off and let the fixture

cool.

CAUTION to avoid fire or burn hazards:

• Allow fixture to cool before touching. The bulb and

fixture operate at high temperatures.

• Keep fixture at least 2" (51 mm) from combustible

materials. Do not aim at objects closer than 3 feet (1 m).

• Re-lamp with type T 300W (or less) halogen 120

VAC lamp only.

❒

Drill out the holes if

needed to mount the

backplate to the junc-

tion box.

Black to

Black

White to

White

❒

Rotate the sensor head towards the clamp screw

joint.

Clamp Screw

Controls

❒

Then rotate the sensor head counterclockwise

180

°

so the controls face down.

Controls

Junction box ground wire

to green ground wire on

fixture.

❒

Remove glass cover and remove the old bulb by

pushing the bulb towards the right until the left side

of the bulb is clear of the left socket.

❒

To insert the new bulb, push the bulb into the right

socket so the bulb fits completely into the left

socket.

❒

Check that the bulb is seated properly.

❒

Re-install the glass cover.

For under eave installation, the sensor head must

be rotated as shown in the next two steps for proper

operation and to avoid the risk of electrical shock.