Post-weld setup, Constant torque option, Hold setup – Dukane 403-570-01 User Manual

Page 44

Dual Servo Spin Welder User’s Manual

Dukane Manual Part No. 403-570-01

Page 3

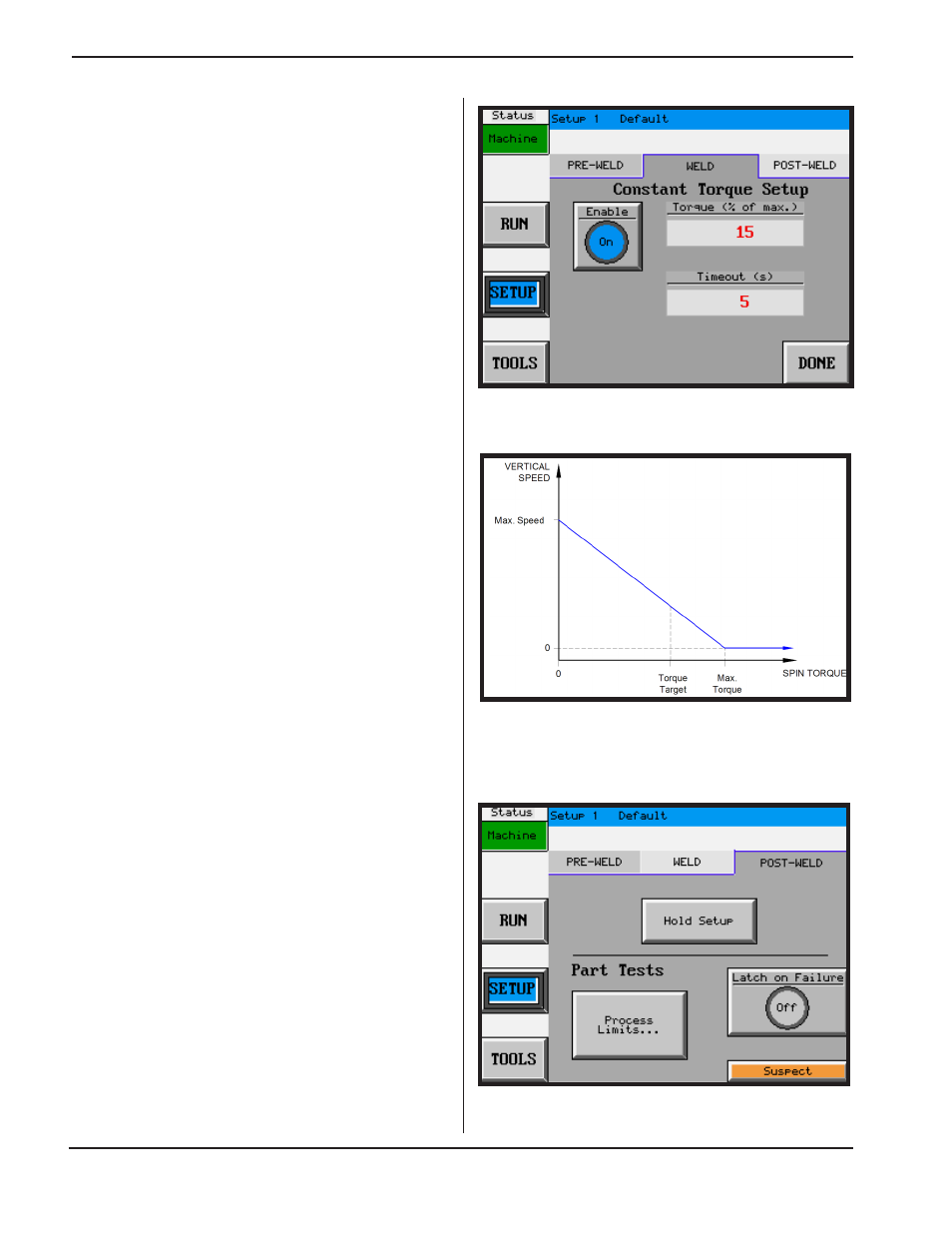

Figure 5–21

POST-WELD Main Setup Screen

Constant Torque Option

This option sets the welder to function in “Melt-Match”

mode, in which the press vertical speed is continuously

adjusted to match the rate of plastic melt at the joint. This

is achieved by measuring the spin torque and changing

the verical speed on-the-fly based on this measurement.

The vertical speed is inversely proportional to the spin

torque: the lower the spin torque, the higher the vertical

speed, and vice versa.

To enable this option, press the

Constant Torque

button

and then the

Enable

box on the screen shown in Figure

5-19. The relationship between the spin torque and

vertical speed is illustrated in Figure 5-20. The welder

will adjust vertical speed for a measured spin torque

along the lines shown. The Torque Target is the desired

spin torque, which is entered into the

Torque (% of max .)

field on the screen. The Max. Torque value is 5% larger

than the Target Torque. If the measured torque exceeds

the Max. Torque, the vertical speed will be 0 until the

torque drops below the maximum. The Max. Speed

is the maximum allowable vertical speed, which will

occur if the measured torque is 0. This value is entered

in the

VERT . Max (mm/s)

field on the

Weld Parameters

screen (in the

WELD

tab). The

Timeout (s)

field specifies

the maximum weld time before the machine aborts the

cycle and reports an error.

The actual spin torque profile achieved during the weld

will depend on the

Torque (% of max .)

and the

VERT .

Max (mm/s)

settings for a particular application. For

example, if the actual spin torque is consistently below

the specified target, the

VERT . Max (mm/s)

will need to

be increased to cause the welder to move down faster,

causing a rise in the spin torque.

POST-WELD Setup

The

POST-WELD

setup is the right tab in the

SETUP

menu and is shown in Figure 5-21. The screen is divided

into two sections:

Hold Setup

and

Part Tests

.

Hold Setup

The

Hold Setup

button is used to enter parameters

related to the Hold phase of the weld cycle. During this

phase, the molten plastic cools and solidifies, beginning

when the spin tool stops. Pressing the

Hold Setup

button

Figure 5–19

Weld Constant Torque Option Screen

Figure 5–20

Graph of Vertical Spin Speed vs . Spin

Torque for Constant Torque Option