Woodhaven 4915: Standard Miter Gauge User Manual

Page 3

2

BEFORE BEGINNING

The Standard Miter Gauge is a precision tool

and should be handled and cared for as such. It is very

important that the miter slot is parallel to the saw blade for

this, or any other miter gauge, to work properly. Identify

and verify that you have all the parts listed. Read the

instructions at least once, familiarizing yourself with the

parts and assembly options, before beginning assembly.

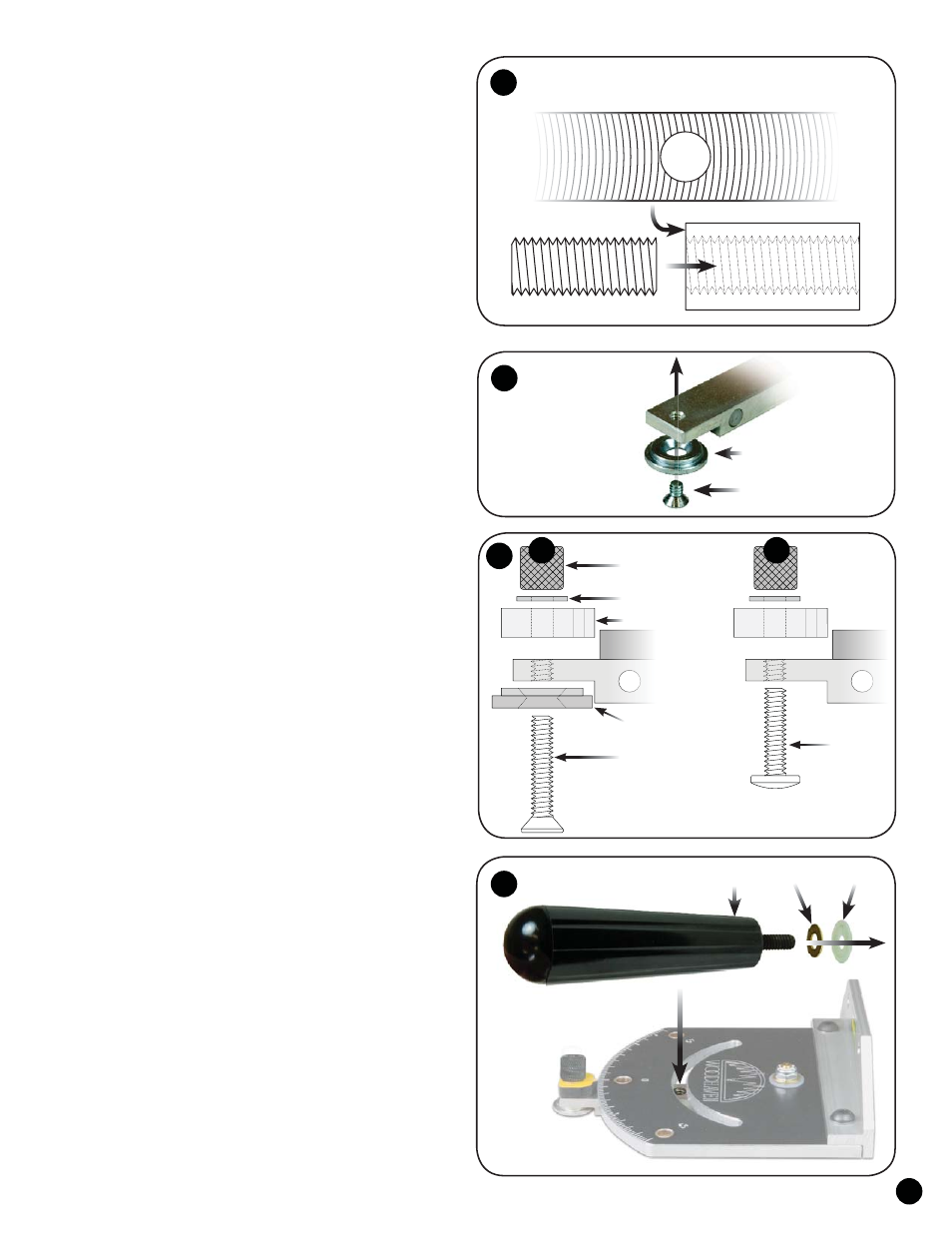

INSTALL MITER BAR SET SCREWS

Carefully install the nylon set screws (four or five

4900A's - quantity depends on model purchased) by hand

in the edge of the miter bar, starting them from the machined

edge (note circular marks - see fig. 1). Use the 1/8" allen

wrench (5784) to turn the set screws until they protrude slightly

from the smooth edge of the bar. Make fine adjustments to

the set screws so the miter bar slides easily in the miter slot,

but without any slop. We have included extra set screws for

future use. If the side of the miter slot is rough, it will wear

the nylon sets screws prematurely. Smooth the miter slot if

necessary with a file or emery cloth. Typically you should not

have to adjust the set screws more than a once or twice a year.

INSTALL T-SLOT WASHERS

The two T-slot washers (4900G) are countersunk on

both sides. This allows them to be reversed for mounting on

a Powermatic or Delta style table saw. Install them on the

front of the miter bar using the 5/16" screw (MF001). For a

Powermatic saw, put the wide side of the washer against the

bar. For a Delta saw, put the narrow side of the washer against

the bar. Leave the washer off if your saw does not have a

T-slot, or if the washer will not fit the T-slot in your saw. The

rear washer is covered under the next section. See fig. 2.

INSTALL POINTER OR VERNIER SCALE

Depending on if you use the rear T-slot washer or not,

the pointer/vernier scale installation will differ slightly:

3A. With rear T-slot washer: Insert a 1" screw (MF045)

into the T-slot washer (4900G), then thread the screw thru

the bottom rear of the bar. Slip the pointer (4910C) or vernier

scale (4910D) on the screw, followed by a 3/16" washer

(WB001) and the knob holder (4900K). See fig. 3A.

3B. Without rear T-slot washer: You don’t use the

T-slot washer and you do use a 3/4" screw (MT015).

Everything else is the same as above. See fig. 3B.

Install the indexing pin in the 0º position, turn the

pointer (4910C) so it is lined up with the 0º scribe line in

the miter head and tighten the knob holder. The vernier

scale (4910D) will work through 80 degrees of rotation. The

drawings of the vernier scale in the parts list show how it

can be used to set angles as fine as 1/10th of a degree.

INSTALL MITER GAUGE HANDLE

Place a 1/4" washer (WB002) and the nylon

washer (WN001) on the stud of the handle (5595D).

The handle installs thru the curved slot in the

miter head and into the miter bar. See fig. 4.

2

4900G

MF001

5595D

WN001

WB002

Identify the machined edge by the circular

marks. Insert set screws from this edge.

1

Miter Head

Miter Bar

4900K

WB001

4910C or D

4900G

MF045

MT015

3

A

B

4