Woodhaven 3010: Rail Kit User Manual

Page 3

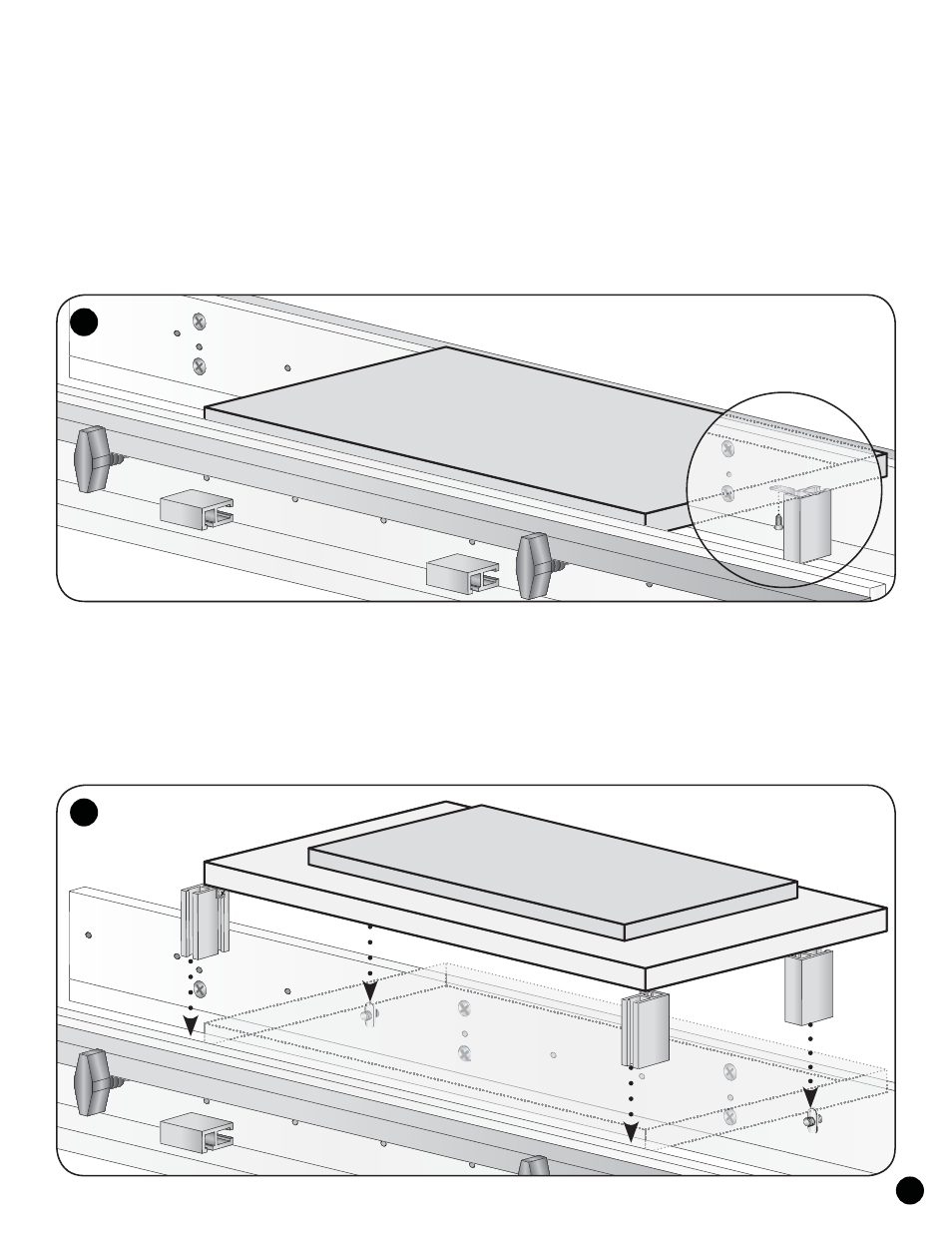

USING ON WORK 2" OR THINNER

The work must have fairly parallel edges. Maximum depth

of cut without repositioning the work is approximately 5/8". For

work that is not too heavy or bulky, set the work face down on a

flat surface, shimming underneath it if necessary so it won't rock

from corner-to-corner or side-to-side. Lay each rail upside down

on the flat surface on either side of the work. Place two 1/4"

shims under the 48" Double Track of each Rail to support it. The

inside of the Rails should be parallel to each other, but not tight

against the edge of the work. Center the length of the work on

the length of the Rails, making sure the ends of the work are at

least 6" in from the ends of the Rails.

Mark and drill four 1/8" pilot holes corresponding to the

holes in the Work Support angle brackets and attach the Work

Supports to the underside of the work using the 1/2" screws

(STP004). See fig. 3

Flip the whole assembly over and clamp the Rails to the

flat surface to begin the planing operation. Depending on work

size and weight, you may be able to set the Rails on non-skid

pads and not use clamps. The Rails can also be attached to a

plywood base or two to three 2 x's fastened from one Rail to the

other.

2

Work

attached to

Work Supports

with

STP004

Work

double-face-taped to

Work Table

attached to

Work Supports

with STP004

If the work is too large or bulky to be safely flipped over with

the Rails attached, set the Rails upright to start out. Attach the

Work Supports to the underside of the work making sure they're

on 4" centers along each long edge of the work and parallel to

each other. Flip the work over and slide the four Work Supports

on to the oval nuts. If the work is large or bulky, this may require

help. See fig. 4

Instead of attaching the Work Supports directly to the

underside of the work, you can make a 3/4" thick work table for

the work to be double face taped to and attach the Work Supports

to the underside of the work table instead. Cut the work table

wider than the widest piece you anticipate planing. This is also

the best method if your part has irregular edges. This method

will reduce the maximum part thickness by the thickness of the

work table. See fig. 4

3

4