Woodhaven 3230-3250: Oval Jigs User Manual

Page 4

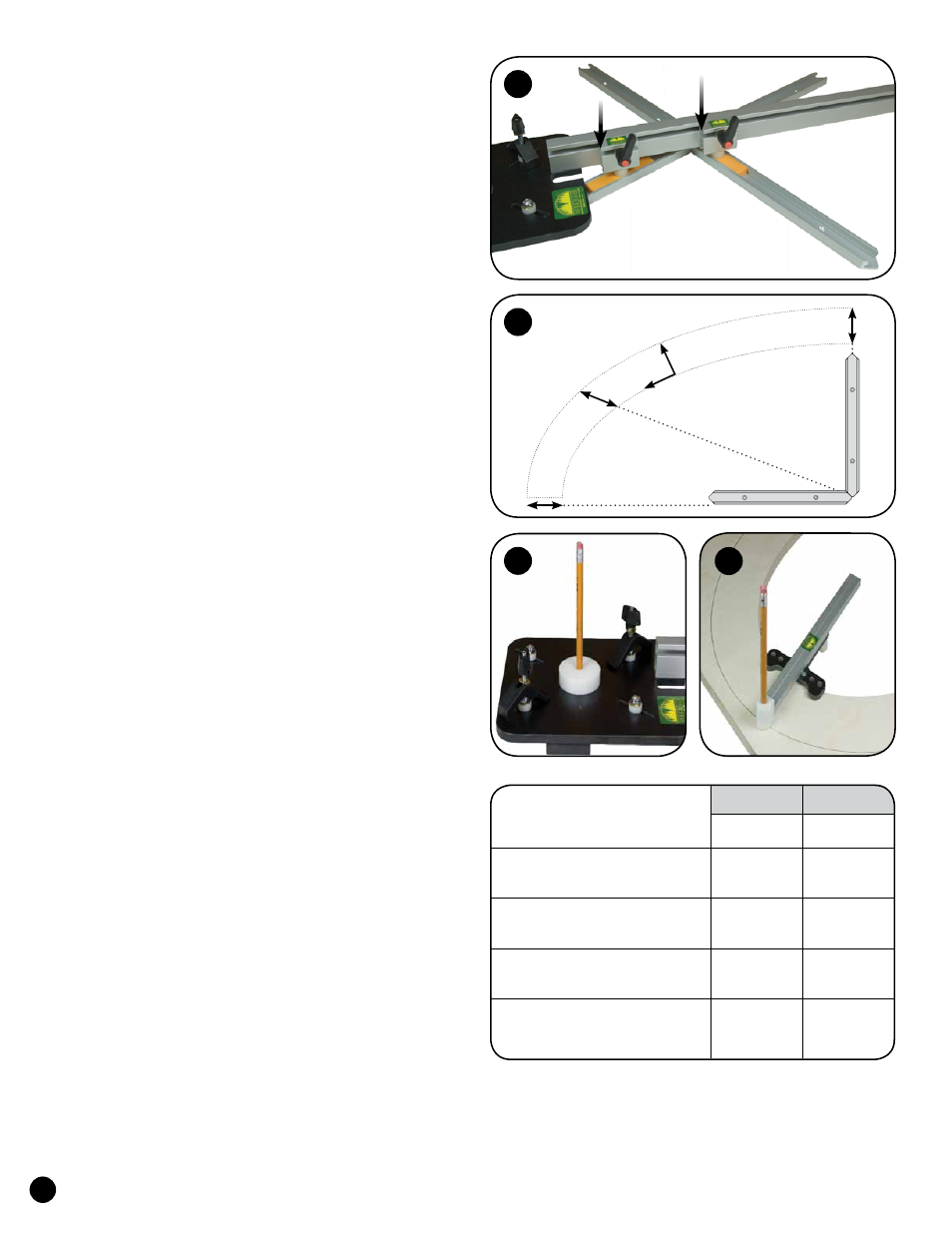

DIFFERENTIAL

Ovals are measured by their length and width. The difference

between the length and width is called the "differential". Using

the same edge of both pivots as a reference, measure the distance

from one edge of a pivot to the same edge on the other pivot.

Multiply this distance by 2 to get the differential. For example,

if the distance between pivots measures 6", then the differential

between the width and height of the oval will be 12". See fig. 9.

The differential range is controlled by the length of the

T-Tracks that came with your Oval Jig. You can increase the

differential range (but not the oval size) of your Oval Jig by

getting longer T-Tracks. We have 12", 24" and 48" T-Tracks

in stock and we can make custom T-Tracks up to 96" long.

OVAL SIZE

The size of the oval is controlled by the distance from

the tool to the pivots. By sliding the tool closer or further from

the pivots (without changing the differential), you can change

the oval size. To set the oval size, loosen the ratchet handles on

both pivots and slide the bar to the desired size. See fig. 9.

For example, if the jig is set to cut a 27" x 60"

oval (23" differential) and you adjusted the router 5"

further away from the pivots (maintaining the 23"

differential) the jig would then cut a 32" x 65" oval.

You can increase the oval size range (but not the

differential range) of your Oval Jig by getting a longer

Double Track, which we offer up to 96" long.

TECHNICAL STUFF

When cutting a 4" wide oval frame, for example, the frame will

only measure 4" at the 0º, 90º, 180º & 270º points. It will measure

slightly narrower everywhere else. This phenomenon is common to

all oval jigs. Actually the jig is cutting 4" wide everywhere, but that's

measured on the travel line of the Double Track, which is not square

to the edge of the part, except at the points mentioned above. The

greater the differential, the more pronounced this is. See fig. 10.

If you need a consistent width, cut one side of the oval

using the jig. Make a tool to follow the edge of the oval that

also holds a pencil. Draw the opposite side of the oval at the

width needed, using the machined edge as a guide. We offer a

handy tool for this purpose called the Margin Scribe, PN 3205.

Routing the inside edge first, then cutting the outside edge

with a band saw, is usually the easiest method. See fig. 12.

ROUTING & DRAWING

When cutting the inside edge of an oval, swing

the router clockwise. When cutting the outside edge

of an oval, swing the router counterclockwise.

Insert the pencil holder (3200D) in the bit opening of the

router plate, insert a pencil (with a blunt point - like a golf pencil)

in the pencil holder to draw the desired oval. See fig 11.

CAPACITIES

The chart on the right lists the cutting capacity of all of

our Oval Jigs. It’s based on the standard T-Track length (or base)

included with each jig. If you need to cut smaller ovals you can

cut the T-Tracks (or base of the 3220/3210), but you will reduce the

differential range. Note that the 3250 measurements do not cover

the full potential differential range available in this jig because it

uses a 72" bar. By getting a 96" bar you can cut even larger ovals.

©Copyright WOODHAVEN INC. 6/24/08

(800) 344-6657 or WWW.WOODHAVEN.COM

3

9

10

11

Example of width variation

on 4” frame

4” @ 180º

4” @ 90º

4” At line

of travel

Less than 4” when

measured @ 90º

from edge

12

3210 Oval Jig

1” to 10” differential

Smallest

Largest

1” x 3-11”

10-18” x 20”

3220 Oval Jig

4” to 12” differential

13” x 17-25”

41-49” x 53”

3230 Oval Jig

7” to 23” differential

25” x 32-48”

54-70” x 77”

3240 Oval Jig

7” to 47” differential

49” x 56-96”

54-94” x 101”

3250 Oval Jig

7” to 95” differential

97” x 104-149”

97-142” x 149”