Workpieces – Woodhaven 4555: Box Joint Jig User Manual

Page 4

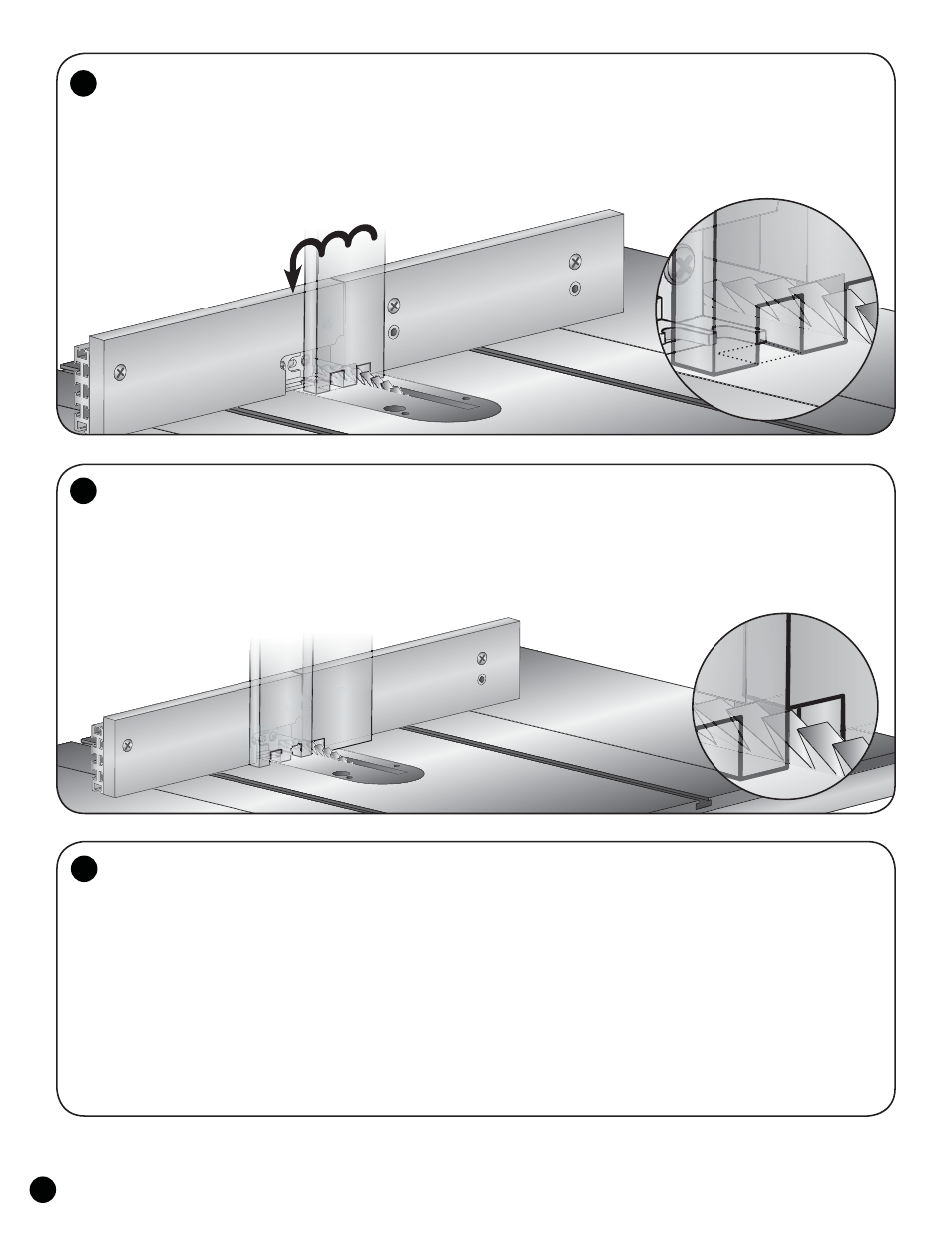

3

To make the mating cuts on the second workpiece, you

need to offset the first cut on the second workpiece by

the width of the joint (which is the same as the width of

the bit/blade). Take your first work piece and flip it edge for

edge so that the first cutout is indexed on the Stops. Butt the

second workpiece against the edge of the first workpiece. Hold

both pieces and make the first cut on the second workpiece.

Remove the first workpiece and continue cutting

the second workpiece as you did the first.

You can cut multiple parts at one time by clamping like

parts together (fronts & backs, left & rights, etc.) as long

as their edges are aligned. Mark the parts (top or bottom

edges, mating corners, outside faces, etc.) to keep them

in order and positioned correctly as you cut the joints.

ACCESSORIES

Replacement fences (4555F) are

available from Woodhaven, or you can

make your own out of 3/4” material.

We offer an Upgrade Kit (4553)

that includes the following:

Two adjustable Work Platforms which provide a

safe and stable surface for the part to rest on. Made of

slick 1/4” thick HDPE, they attach to the underside of

the Ultra Track and eliminate friction between your saw

or router table and the bottom of your workpiece.

Includes an Adapter Head of 3/4” MDF for attachment

to your miter gauge so you don’t have to make your own.

Includes a Stop that attaches to the back of the

Ultra Track. The Stop indexes against the side of the

Adapter Head to help fine tune the joint size. This

replaces the clamp and wood block in step 6 you’d

otherwise have to supply for the fine adjustment.

Includes a bit/blade Shield that attaches to

the top of the Ultra Track and projects out the back

where the bit/blade exits for safer cutting.

Includes a five piece set of Setup Jigs for quicker

and easier setups of 1/4”, 3/8”, 1/2”, 5/8” & 3/4” joints.

©Copyright WOODHAVEN INC. 2/20/14

(800) 344-6657 or WWW.WOODHAVEN.COM

8

9

First

workpiece

Workpieces

Start of

Second

7

1/2”

After you are satisfied with the fit of the joint,

hopscotch the work over the Stationary Stop, place

the left edge of the cutout (looking at it from behind)

against the Stationary Stop. Loosen the 1/2” screw of the

Adjustable Stop, slide it away from the Stationary Stop until

it butts against the opposite side of the cutout, then retighten

the screw. The work should now be captured between both

Stops so the work can’t shift left or right while cutting.

Continue cutting along the entire width of the work, hop-

scotching each cutout over the Stops to index the work for

each cut. Set the cutting height of the bit/blade to the thickness

of work plus 1/32”, or the minimum 1/4”, whichever is

greater. Any overhang can be removed later after assembly

by sanding or flush trimming. Make sure you allow for this

overhang when figuring the overall length of the workpiece.