Stop assembly, Sub-fence assembly – Woodhaven 4555: Box Joint Jig User Manual

Page 2

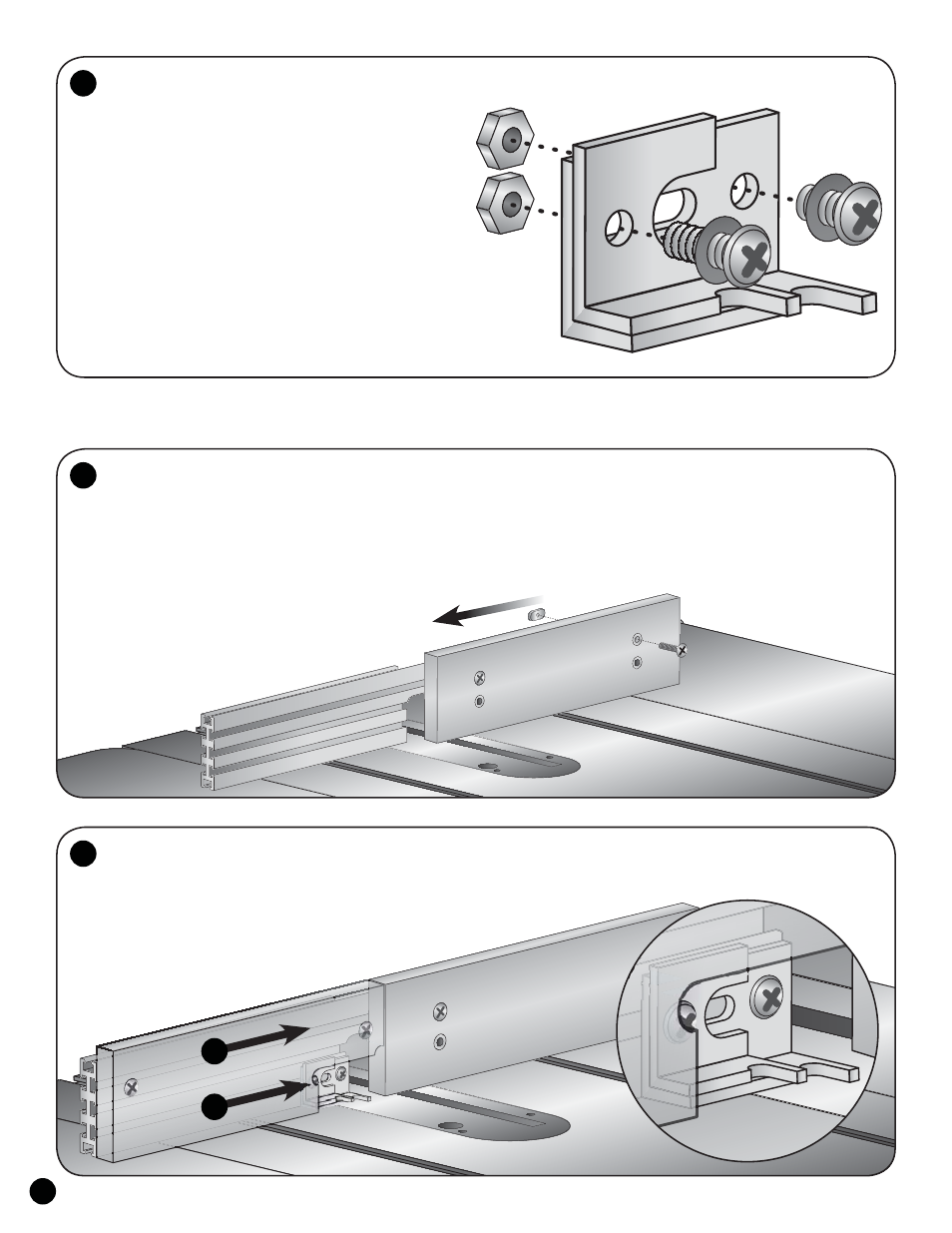

STOP ASSEMBLY:

The 4555S Stop is assembled with two aluminum

angle components and hardware: Stationary Stop - angle

with a slot and a hole, and an Adjustable Stop - angle with a

notch and a hole.

Place the Adjustable Stop on top of the Stationary

Stop. Install a washer (WS001) on the 3/8” screw (MP375)

placing it thru the right hand hole in the Stationary Stop,

starting a nut (NUT007) on the other side. Install a washer

(WS001) on the 1/2” screw (5770B) and insert it thru both

the hole of the Adjustable Stop and slot of the Stationary

Stop, starting a nut (NUT007) on the other side.

1

NUT007 - Nuts

5770B

WS001

MP375

WS001

MF015

5760B

Adjustable Stop -

Front

Stationary Stop -

Rear

4555F

4555A

4555F

4555S

1

SUB-FENCE ASSEMBLY:

The 4555F Sub-Fence is a two piece set. Both pieces

are rectangular in shape with one of the pieces having a

rectangular cutout. Install the 1” flathead screws (MF015) into

the countersunk holes in both MDF Sub-Fences (4555F) and

start oval nuts (5760B, raised side first) on the ends of the

screws.

With the bottom edge of the 24” Ultra Track (4555A)

resting on a flat surface, install the rectangular Sub-Fence

(without the cutout) on the Track. The oval nuts will

slide in the upper T-slot of the track. Position the end of

the Sub-Fence even with the end of the track and tighten

the screws. This Sub-Fence has an extra set of holes so it

can be rotated 180º and the opposite end can be used.

Install the Stop assembly (A - 4555S) on the

Track by inserting the nuts in the lower T-slot of the

Track. With the bottom edge of the Track resting on

a flat surface, slide the Stops to the right, against the end

of the rectangular Sub-Fence, and tighten both screws.

Install the remaining MDF Sub-Fence (B - 4555F

with the cut out) on the track, butted up against

the first Sub-Fence and tighten the screws.

2

3

A

B