Spectrum Controls 1746sc-INO4vi User Manual

Page 21

Chapter 2: Installing And Wiring Your Module

11

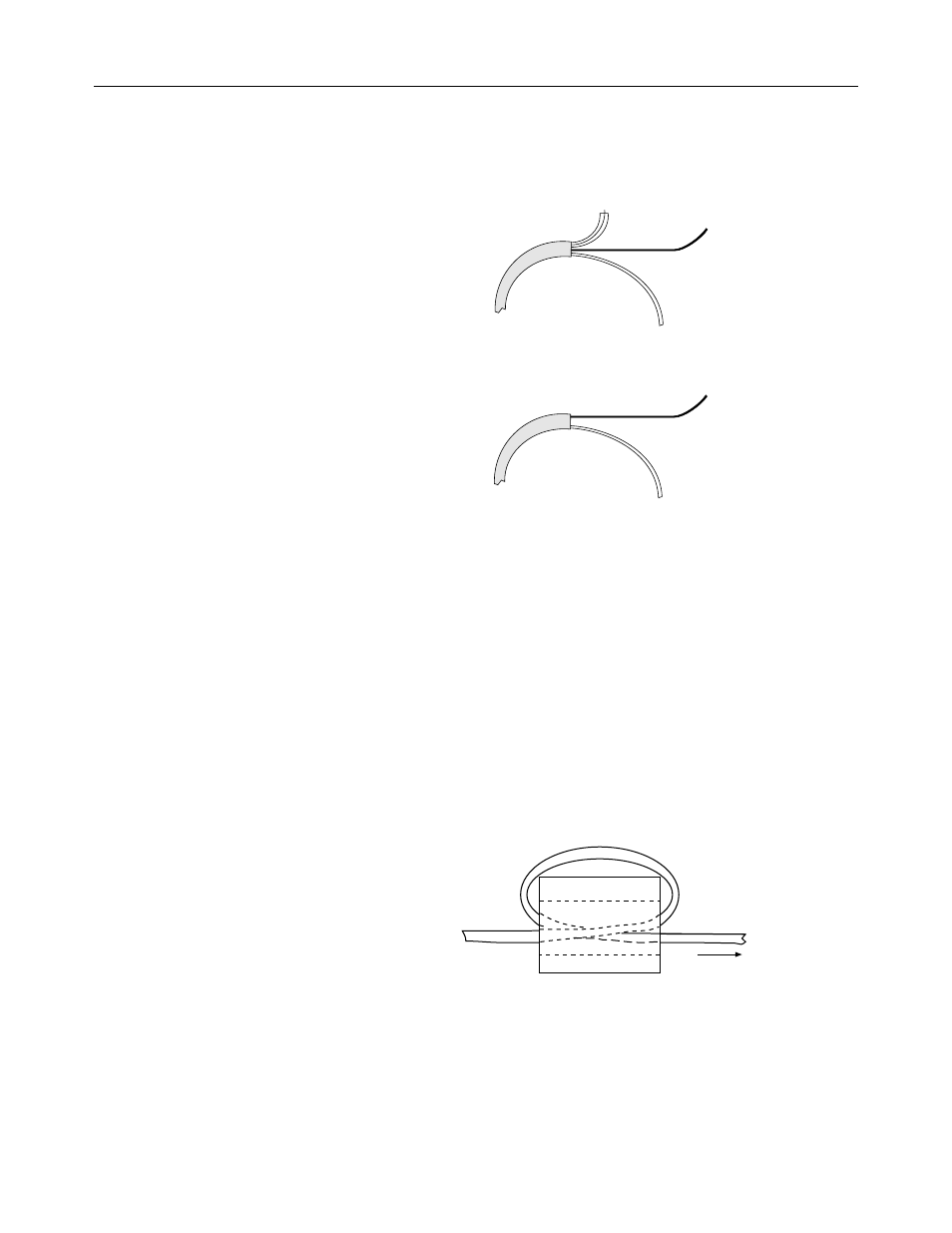

4. At one end of the cable, twist the drain wire and foil shield together,

bend them away from the cable, and apply shrink wrap.

Insulation

Clear Wire

Black Wire

Foil Shield and Drain Wire

5. At the other end of the cable, cut the drain wire and foil shield back to

the cable and apply shrink wrap.

Insulation

Clear Wire

Black Wire

6. Connect the wires to the terminal block and field device as shown in

the following figures and table. The recommended maximum torque is

5 in-lb (0.565 Nm) for all terminal screws.

To guard against electrostatic damage and improve chassis grounding,

connect one of the shield pins on the terminal block of your module to

the chassis itself.

Important: For CE compliance, Ferrite EMI Suppressors are needed

on each channel’s terminal block connection. Apply the suppressor

close to the module terminal block, as shown below. A Steward Part

28B2024-0A0 or equivalent is recommended. The Steward 28B2024-

0A0 has an impedance of 157

Ω

at 25 MHz, 256

Ω

at 100 MHz, and

can accommodate one turn of wire.

Figure 1. Ferrite EMI suppressor for CE compliance

Module

7. Repeat steps 1 through 6 for each channel on your module.

A system may malfunction due to a change in its operating environment.

After installing and wiring your module, check system operation. See the

Allen-Bradley system Installation and Operation Manual for more

information.