Viscous sensor installation (series 371-v) – SOR Single Point Ultrasonic Level Switch User Manual

Page 3

Form 771 (08.13) ©SOR Inc.

3/20

Open Sump or Basin

Do not suspend the unit by rigid conduit installed

in the electrical hub. When installing the unit over

an open sump or basin, use a suitable bracket to

support the instrument.

Open Sump

Locally

Supplied

Bracket

CE Marking Sensor Installation (notch type sensors only, Series 371-N)

Shield Beads

Three beads are included with your CE marked unit.

Two of the beads are 5/8” dia x 1/2” long. The other

bead is 3/8” dia x 3/4” long (save this bead for the

electrical connection beginning on page 5).

Disconnect the sensor leads from the circuit board.

Slide one 5/8” dia. bead onto each lead.

Reinstall the sensor leads into the circuit board.

Push the beads to the bottom of the housing. (See

)

Sensor

Wires

Sensor

Electronics

Housing

Shield

Beads

NOTE: The instrument must be positioned so that

overfl ow does not fl ood electrical housing. (See

)

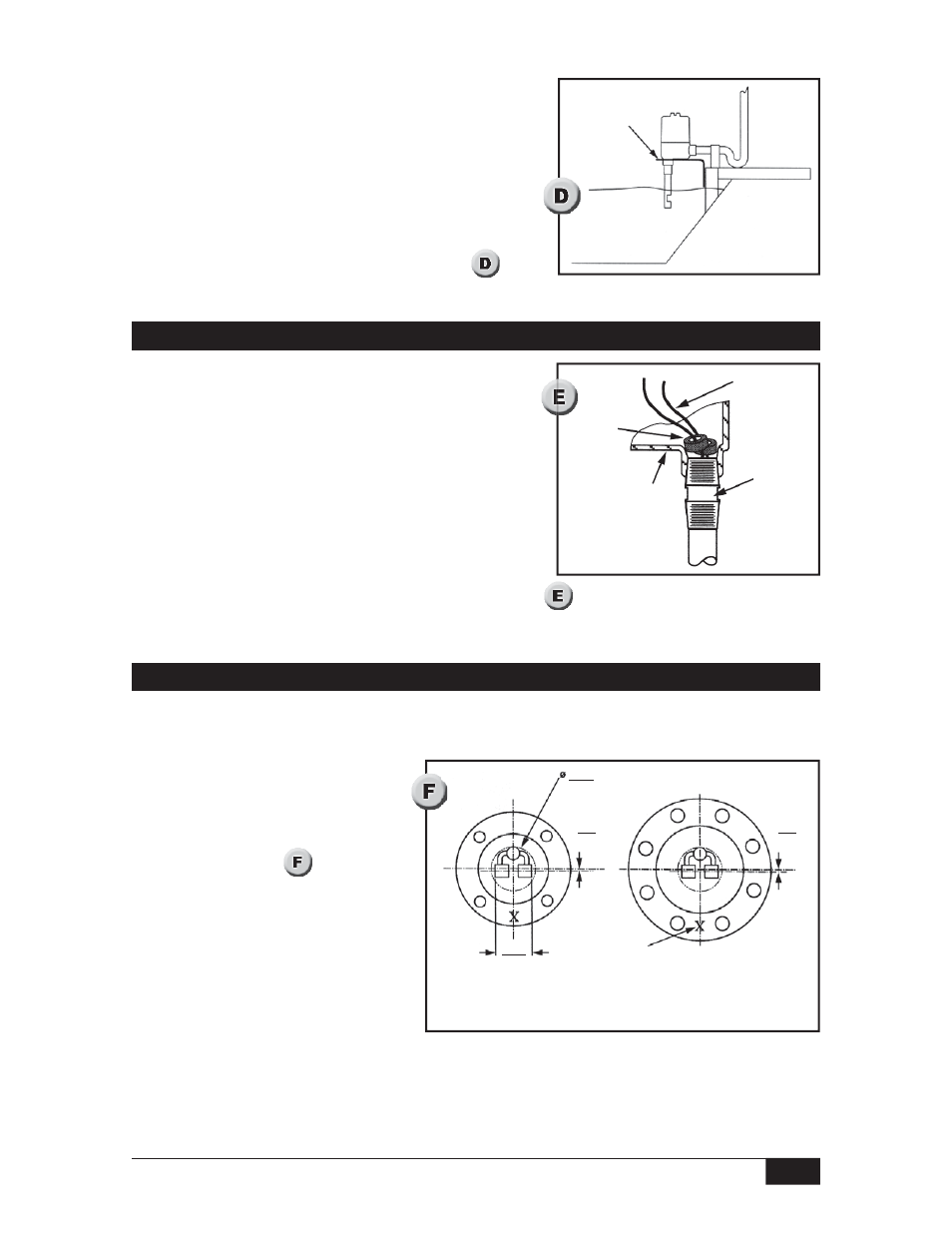

Viscous Sensor Installation (Series 371-V)

Vertical or horizontal (flange only) mounting is supported for the viscous sensor. A 3”

(76.2mm) minimum opening is required for insertion.

76.2

3.00

minimum opening required (typ.)

5.9

0.23

Bottom View Viscous

Sensor with 8-Hole Flange

Alignment mark, (other side)

position at 6 o’clock (typ.)

Bottom View Viscous

Sensor with 4-Hole Flange

62.1

2.44

(typ.)

5.9

0.23

C

L

of fl ange

An alignment mark X stamped on

the dry face of the flange below

the housing shows sensor cav-

ity orientation. (See

) When

mounting the viscous

sensor horizontally, optimum

drainage occurs when the X mark

is located in the 6 o’clock position.

Take care during installation to

prevent damage to the sensor

end. Slight bending of the sensor may result in loss of sensitivity due to misalignment of

the ultrasonic crystals.