SOR Single Point RF Level Switch User Manual

Page 2

2/16

Form 759 (03.13) SOR Inc.

Turn the sensitivity adjustment slowly clockwise until LED goes off, then

counterclockwise until LED goes on to check the null position to verify that the bridge is

balanced. It is desirable to closely bracket the position where the LED came on.

Turn the sensitivity adjustment one turn counterclockwise from the null position. Next,

slowly move a hand toward the probe to touch it. The LED should stay on until the

probe is touched. If it goes out when the hand is near, turn the sensitivity control

counterclockwise so the LED stays on until the hand touches the probe. Usually,

1-2 turns will locate the new null point.

When practical, use a small container of actual process material to calibrate the control.

If the actual process vessel is metal, use a metal container (coffee can, etc.) and ground

it to the instrument housing. If the actual process vessel is an insulator, such as,

fiberglass, use a plastic container.

Immerse the sensor in the process material; the LED should turn off. If not, rotate the

sensitivity adjustment clockwise until the LED goes off.

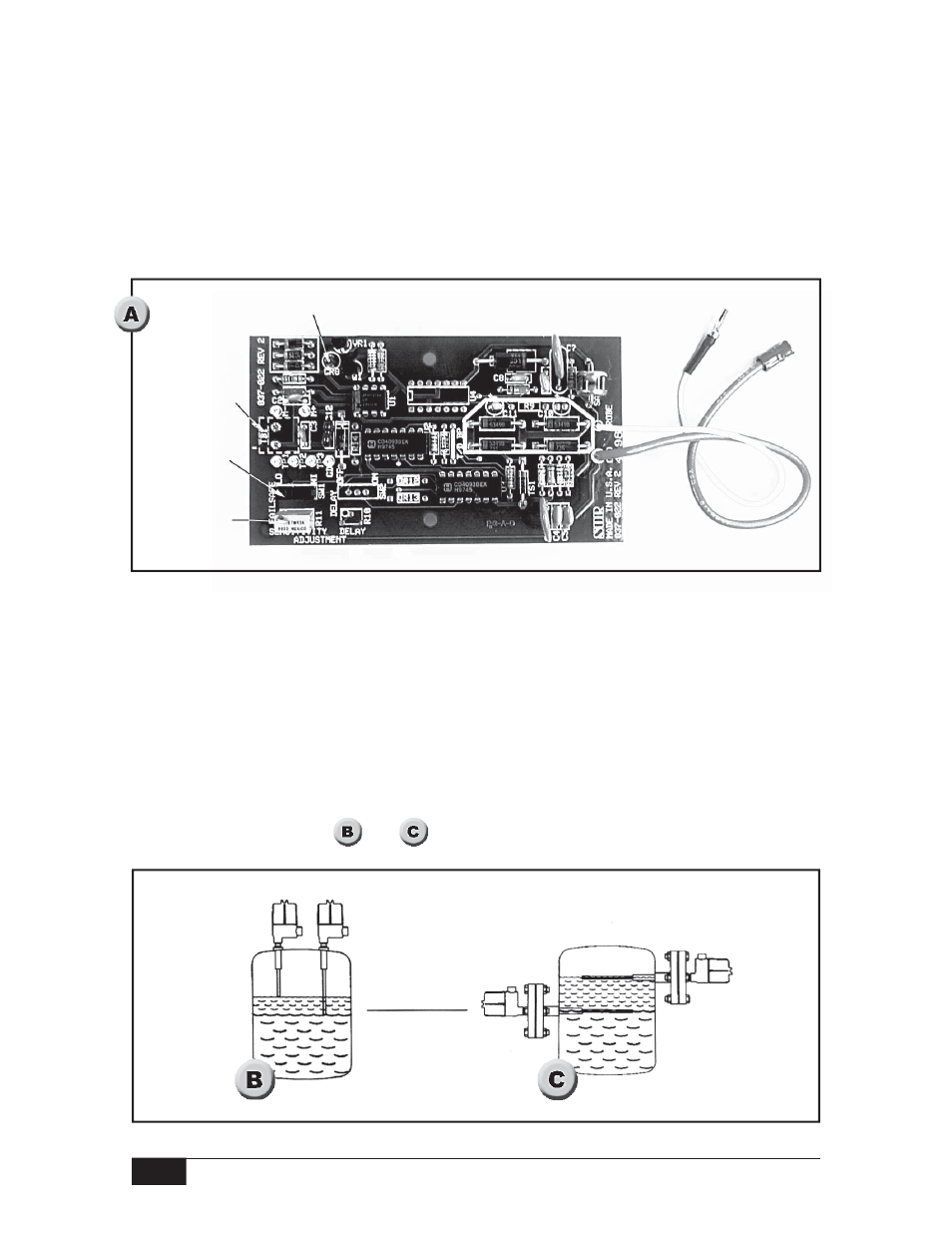

To detect an interface, such as oil/water or foam/liquid, the lighter material must be in

contact with the sensor, then tuned out. Then adjust the sensitivity to detect the heavier

process material. (See

and

)

Oil

Water

Terminal Block

(opposite side)

Fail Safe

Switch

Sensitivity

Adjustment

Banana

Plug

LED

Ring

Terminal