Single switch chamber installation – SOR Sealed Level Switches User Manual

Page 3

Form 1428 (01.14) ©SOR Inc.

3/8

Insulation of the control chamber is acceptable, but switch housing and

cover must not be insulated.

Not following these installation instructions, including pipe and valve

diameter and pipe lengths can affect operation of the switch, including

differential. See Single Switch Chamber Installation

and Multiple

Switch Chamber Installation

.

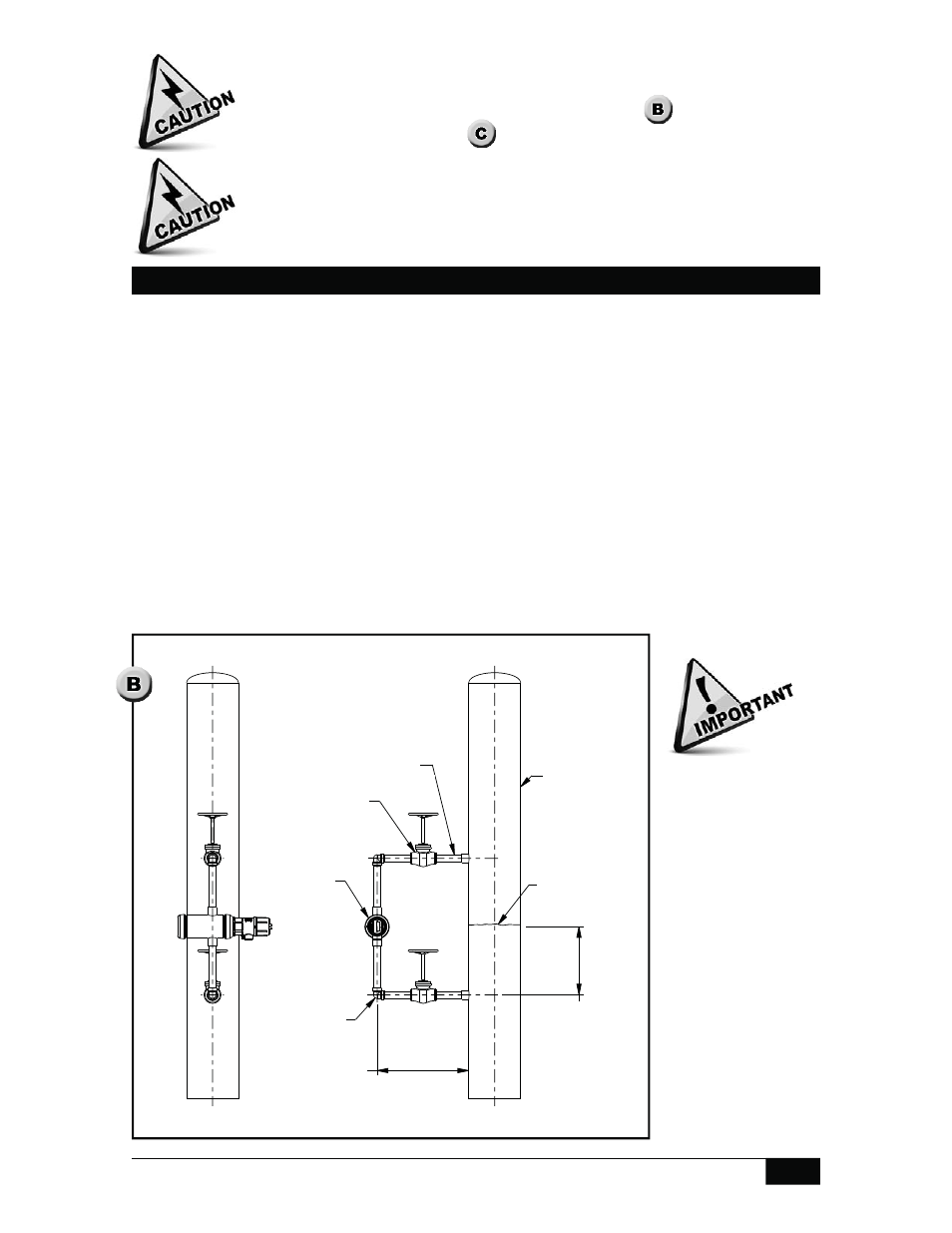

Locate switch chamber process connection 12” to 24” (300mm to 600mm) away from

the process pipe or tank.

Locate the switch chamber so that the switch actuates or deactuates at the desired level.

For liquids with a specific gravity of 1.0, switch actuation will occur approximately 3/4”

(20mm) above the chamber centerline and deactuation will occur at approximately 3/8”

(10mm) above the chamber centerline. Consult factory for other specific gravity values.

Connect the bottom chamber process connection to the process pipe or tank 6” to 12”

(150mm to 300mm) below the centerline of the chamber. This will ensure liquid level

in the switch chamber is as close as possible to process liquid level.

Inside diameter of piping, including elbows, tees and valves, must be equal to or

greater than process connection diameter.

One elbow is recommended to connect the level switch with the process pipe or tank.

Single Switch Chamber Installation

Deviating from any

of these instructions

may adversely affect

operation of the level

switch by restricting

liquid fl ow into the

switch chamber.

The recommended

dimensions allow

adequate space for

isolation valves,

pipe fi ttings and

insulation. Structural

support (not shown)

must be provided

for level switch

chambers.

152.4

304.8

TO

6.0

12.0

RECOMMENDED

304.8

609.6

TO

12.0

24.0

RECOMMENDED

ELBOW

ISOLATION

VALVE

2210 LEVEL

SWITCH WITH

EXTERNAL

CHAMBER

LIQUID SET

POINT

PROCESS TANK

PIPE

Drawing 0390736