Installation – SOR Sealed Level Switches User Manual

Page 2

2/8

Form 1428 (01.14) ©SOR Inc.

ISO-9001

14685 W 105TH ST LENEXA, K

913-888-2630

SORINC.COM

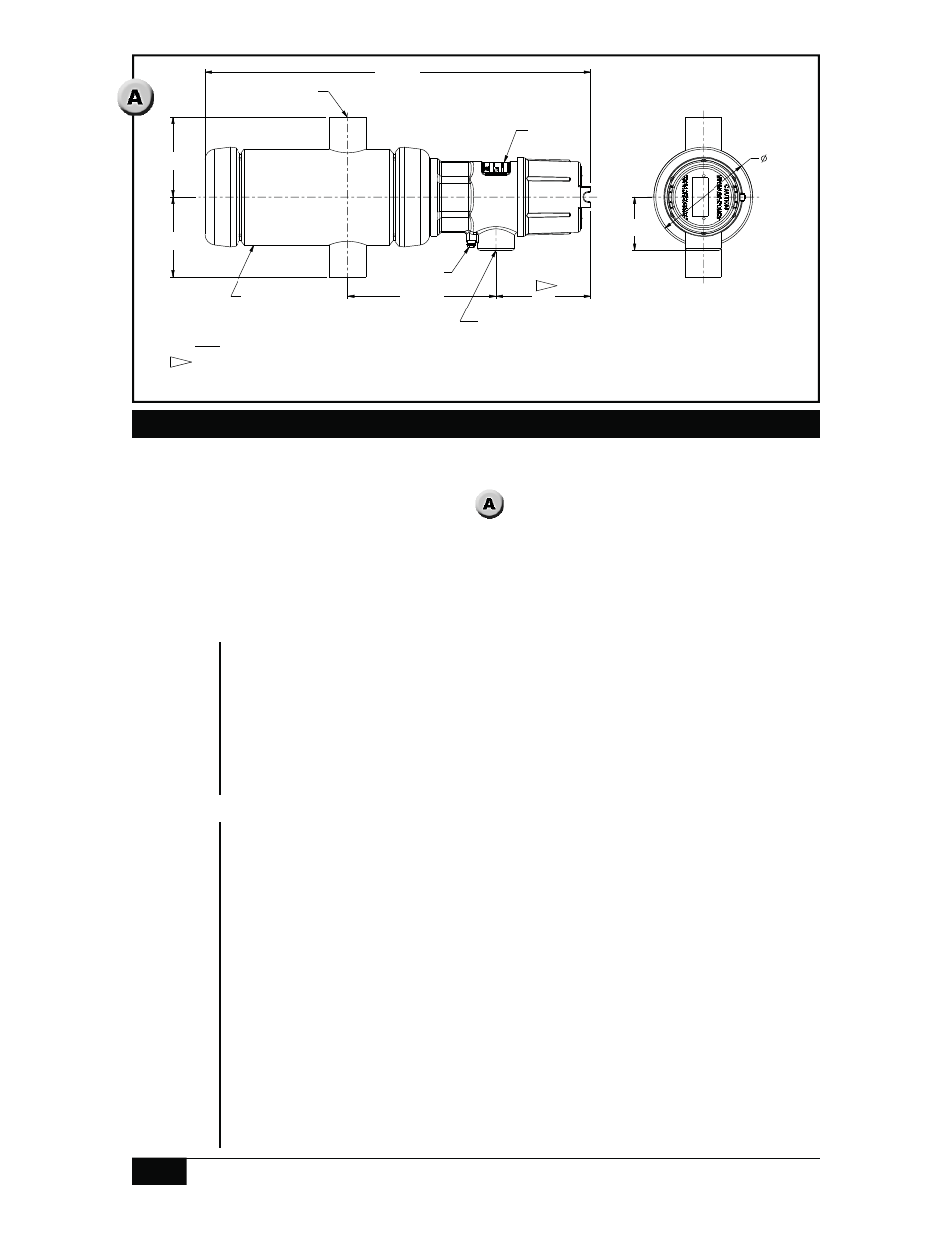

459.6±14.2

18.10±0.56

112.6

4.43

118.6

4.67

*

95.1±6.3

3.75±0.25

*

95.1±6.3

3.75±0.25

176.4±11.1

6.95±0.44

63.5

2.50

1" NPT

8

3

1" SW

PRODUCT CERTIFICATION DRAWING

ALL DIMENSIONS ARE ±1/16 IN

UNLESS OTHERWISE SPECIFIED

MM

LINEAR =

D

J

CH

M

EN

R

10-32 EXTERNAL

GROUND SCREW

4 IN SCH 40

EXTERNAL CHAMBER

ELECTRICAL CONNECTION

1 NPTF STD

3/4 NPTF OPT

1/2 NPTF OPT

M20 X 1.5 F OPT

2X 1 IN 3000# SW

PROCESS CONNECTION

NAMEPLATE

FRONT VIEW

LEFT SIDE VIEW

1

Installation

Multiple

Switch

Chambers

External switch chambers must be mounted so that the centerline is within 3º of

horizontal. The conduit connection centerline must be within 3° of vertical and the

nameplate at 12 o’clock (facing up - see

). Switch actuation cannot be reversed

by rotating the unit 180°.

Pipe support hangers or stands should be used where necessary.

All isolation valves must be fully open during service, as restricted valves may

cause erroneous level switching.

Single

Switch

Chamber

In addition to the Single Switch installation instructions, multiple chamber

installations have the following requirements:

Headers connecting multiple chambers to the process must be larger

than the chamber process connection diameter to allow adequate liquid

flow to all chambers. Header diameters are listed below:

- Header diameter must be 1.5 times larger than process connection

diameter for two chambers.

- Header diameter must be 2 times larger than process connection

diameter for three or four chambers.

- Header diameter must be 2.5 times larger than process connection

diameter for five or more chambers.

Valves, tees, elbows and other pipe fittings in a header must be the

same diameter as the recommended header diameter.

External chamber piping should be short, straight and unrestricted.

Pipe must be of a diameter equal to or greater than the process

connection diameter.

Valves and other equipment between the chamber and process

must be of the same diameter or larger than the process connection

diameter to allow adequate liquid flow into the chamber.

Dimensions are for reference

only. Contact the factory for

certified drawings for a

particular model number.

Linear = mm/inches

Drawing 0390698

NOTES:

112.8

1. ADD MINIMUM

CLEARANCE

4.44

REQUIRED TO REMOVE HOUSING COVER

1