SOR 805PT Pressure Transmitter User Manual

Page 2

2/8

Form 1435 (10.13) ©SOR Inc.

1st Step: Make the Process Connection

The process connection is threaded onto a fitting within an adequately supported

process piping system.

Use two open end wrenches when connecting the pressure port to a process piping

system: one wrench to hold the process fitting, the other at the hex flat to tighten the

pressure transmitter.

Process connection pipe or tubing may be rigid or flexible.

NOTE: Do not use the 1/2” NPT(M) connection on pressures higher than 5000 psi.

2nd Step: Make the Electrical Connection

The electrical connection may be installed on an adequately supported rigid conduit

system. Use suitable locknuts (not provided) when mounting the instrument to an

unthreaded (knockout) hole.

Securely connect the conduit pipe or fitting by holding the flats on the electrical

connection while tightening.

Electrical connection may be rigid or flexible conduit.

Unit in Hazardous Locations - Prior to removal from service, make sure that the

work area is declassifi ed. Failure to do so could result in severe personal injury

or substantial property damage.

Additional Install Steps for Dual Seal Units

Failure to follow these additional installation instructions may

diminish the “Ingress Protection” and “NEMA” ratings of the

“Dual Seal” instruments. An improper installation will void

the warranty.

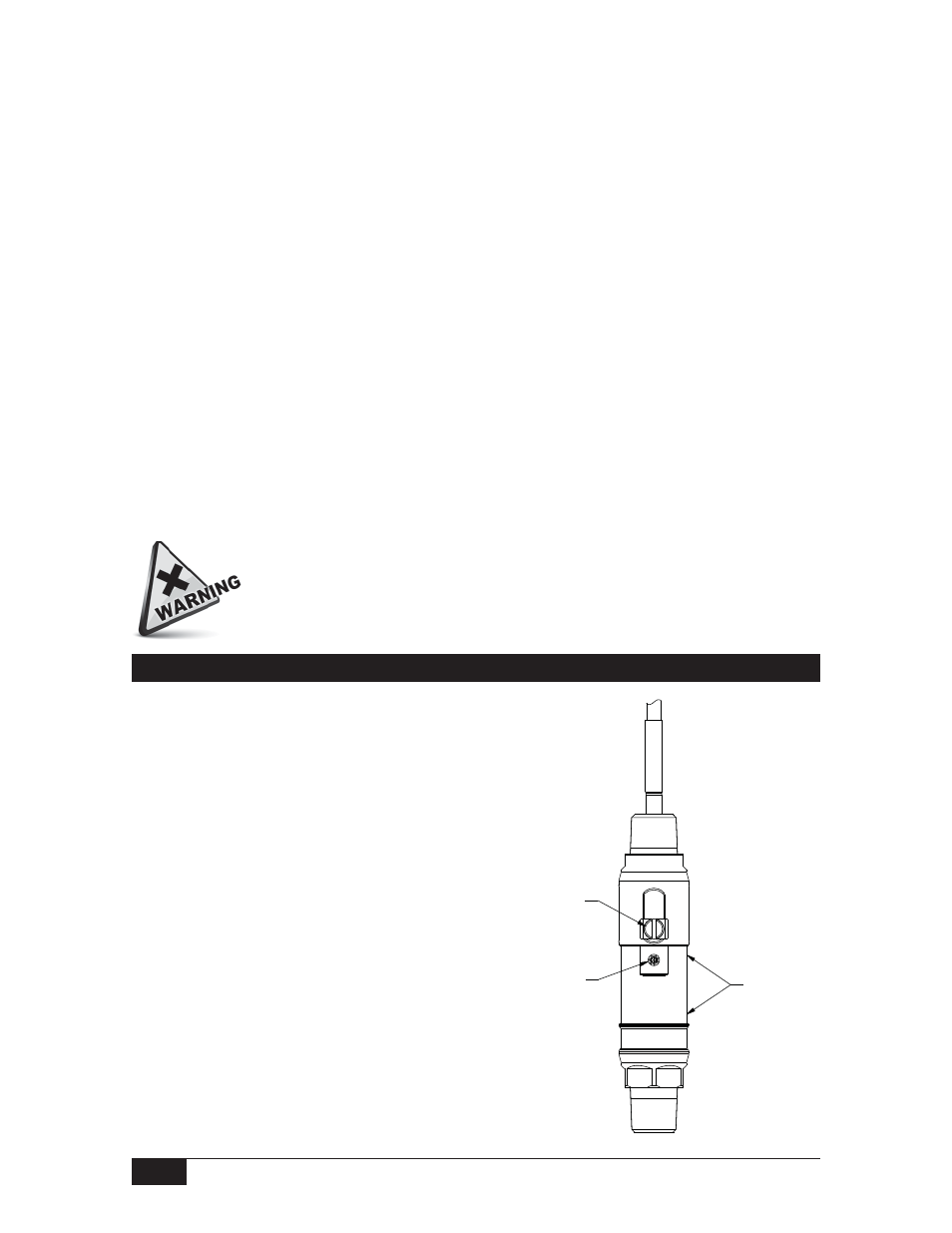

SET SCREW

ANNUNCIATION PATH

NAMEPLATE AREA

EXTERNAL GROUND

PROVISION

Vertical Installation

The figure on the right depicts the vertical

installation profile; with the electrical

leads on top. The instrument may be

installed with the electrical leads on the

bottom.

The nameplate (tag) should cover the set

screw (annunciation path). Position the

nameplate slot opposite the set screw;

i.e., the nameplate slot should be located

180° from the set screw.