2 water system – Glow-worm EnergySaver 80 User Manual

Page 9

9

221837B

0246M

2 Water System

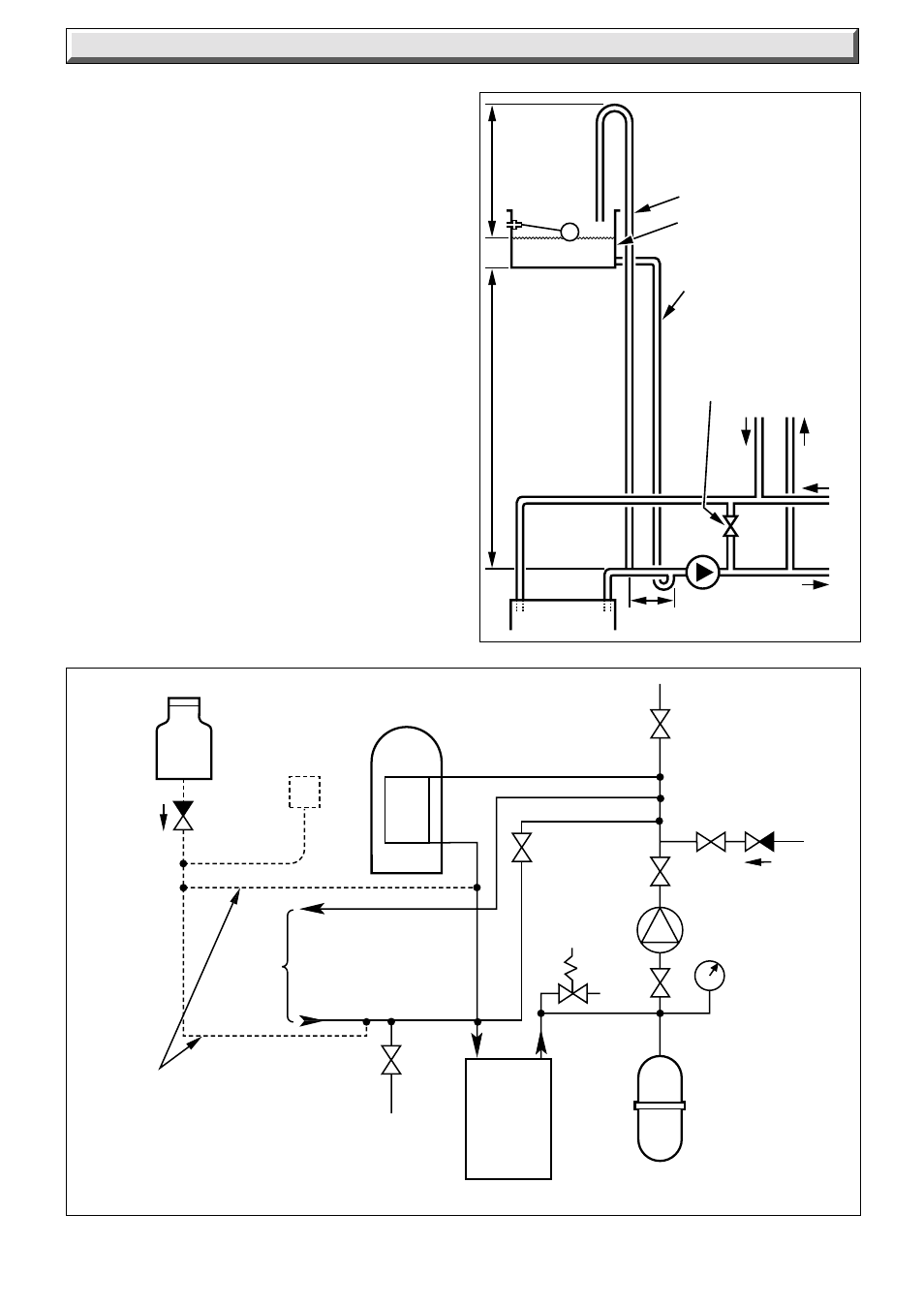

Diagram 2.3

Diagram 2.4

3 LITRES (0.66 gals)

MAKE-UP BOTTLE

(if required)

NON-RETURN

VALVE

AUTO

AIR

VENT

FLOW

DRAIN

COCK

BOILER

SAFETY

VALVE

(Make-up

alternatives)

EXPANSION

VESSEL

PRESSURE

GAUGE

CIRCULATING

PUMP

FILLING POINT

AIR

RELEASE

POINT

HEATING

CIRCUIT

22mm (min)

BY-PASS WITH

LOCKSHIELD

VALVE

RETURN

Open (vented) ststem.

Recommended

rellationship between

pump,cold feed and vent.

22mm (MIN.) VENT

FEED AND

EXPANSION

CISTERN

15mm (MINIMUM)

COLD FEED

22mm (MINIMUM) BY-

PASS WITH

LOCKSHIELD VALVE

1150mm

MIN.

BOILER

150mm

MAX

FLOW

PUMP

RET.

CYLINDER

FLOW

RET.

HEATING

450mm

MIN.

HEIGHT

2.8 Domestic Hot Water System - Unvented

Where a storage system will not have a vent to atmosphere the

installation must comply with the Building Regulations and local

Water Company bylaws, see also the current issue of BS5546

and BS6700.

If fitting to an existing system the local authority should be

informed.

2.9 Sealed Water Systems

The installation must comply with the appropriate requirements

of the current issue of BS4814, BS5449, BS6759, BS6798 and

BS7074 Part 1 and 2.

See diagram 2.4 for a suggested layout.

2.10 Safety Valve

A safety valve must be fitted to a sealed system.

It shall be preset, nonadjustable with a lift pressure of 3bar,

incorporating seating of a resilient material, a test device and a

connection for drain.

The drain from the safety valve must be routed clear of any

electrical fittings and positioned so that any discharge can be

seen.

5814