12 servicing – Glow-worm EnergySaver 80 User Manual

Page 24

24

221837B

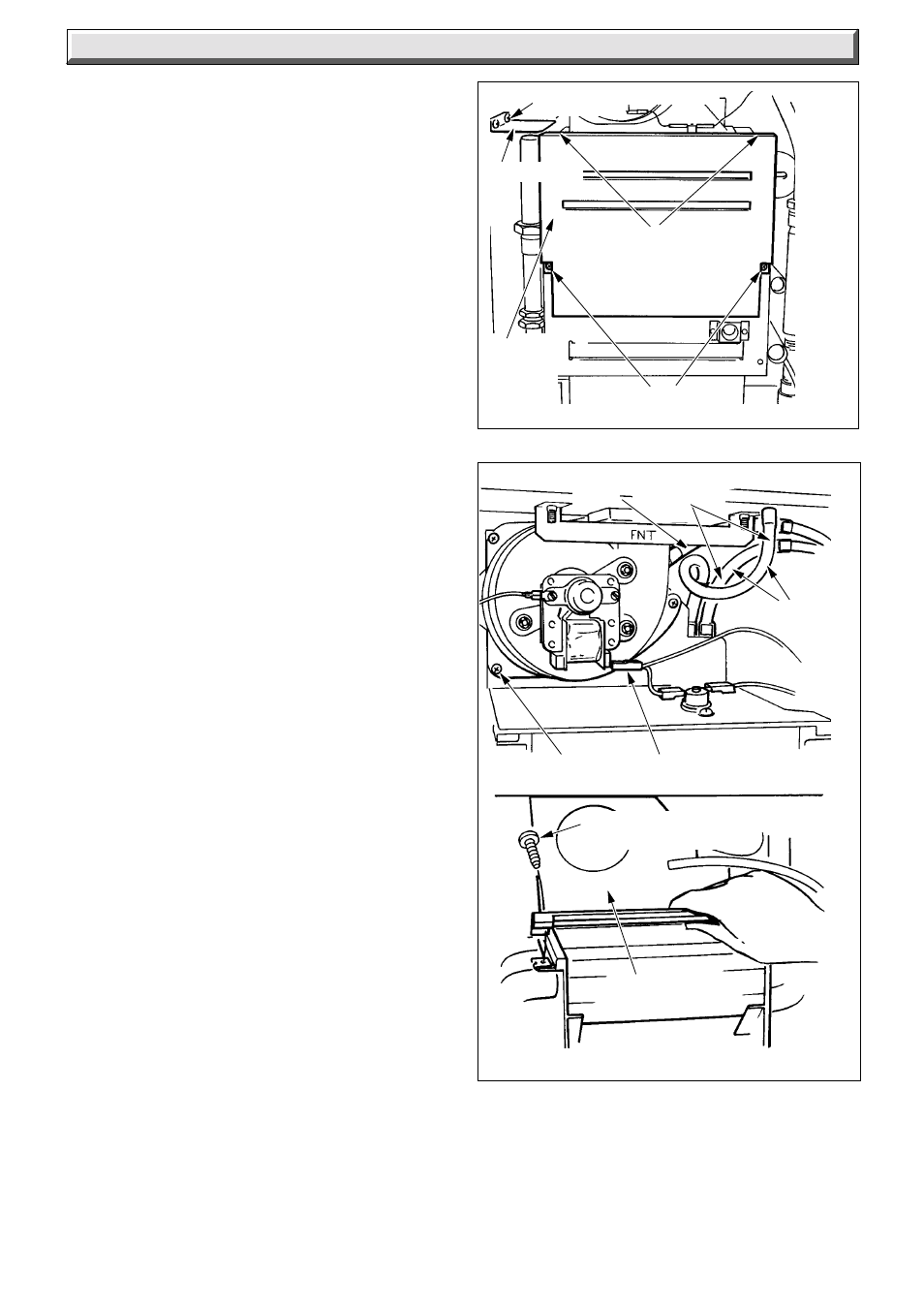

Diagram 12.3

4055 S

4043 S

AIR PRESSURE

TUBES

CLEAR

TUBES

RED

TUBE

SECURING

SCREWS (3)

ELECTRICAL

CONNECTIONS

FLUE HOOD

FLUE HOOD

SECURING SCREW (2)

Diagram 12.1

SECURING SCREW(2)

AIR BAFFLE

SECURING

SCREW(2)

BYPASS

HEAT

SHIELD

SECURING SCREW (2)

4372 S

12 Servicing

NOTES:

To ensure the continued efficient and safe operation of the

boiler it is recommended that it is checked and serviced at

regular intervals. The frequency of servicing will depend upon

the particular installation and usage, but in general once a year

should be enough.

It is the Law that any servicing is carried out by a competent

person.

Note. To get a products of combustion reading use the

connection on top of the boiler, see diagram 6.1.

Should the gas pressure need adjusting refer to Section 10.4.

Isolate the boiler from the electrical supply.

Before starting a service, remove the casing, refer to diagram

5.1.

Turn the gas supply off at the gas service cock, see diagram 8.1.

Unless stated otherwise, parts removed for servicing should be

replaced in the reverse order to removal.

After completing any servicing of gas carrying components,

ALWAYS test for gas soundness and carry out functional check

of controls.

Also check for condensate leaks at fan outlet/flue elbow and fan

inlet/flue hood joints.

It should be noted that the burner is water cooled and a system

drain down is necessary if the burner is removed.

12.1 Heat Exchanger Cleaning

Remove the inner case cover, see diagram 5.3.

Remove the bypass heat shield and air baffle, see diagram

12.1.

Note. The flue hood top will “spring” up.

Disconnect the fan air pressure tubes, combustion sampling

tube, electrical connections and remove the three fan securing

screws, fan securing bracket, then fan and the flue hood.

Note. On reassembly it is suggested that the two top securing

screws for the bypass heat shield and the flue hood be partially

engaged before fitting of the bypass heat shield, see diagram

12.3.

Carefully remove the combustion chamber front panel, see

diagram 12.4.

Remove the loose baffle from the condensing section, see

diagram 12.5.

Place a container under condense drain trap, see diagram

12.8, and remove red cap.

Flush loose debris from secondary heat exchanger with

water poured from above, and allow the water to drain

through the flexible condensate tube at the right hand side

of heat exchanger into the container.

Check that this tube is not partially blocked and the water

runs freely.

If there is any build up of debris in the condensate trap, the

trap should be removed and flushed out.

Important: With use a white oxide coating will form on the

aluminium parts - this should only be removed if the coating is

blocking the gaps between the fins.

When cleaning take care that the water does not overflow the

condensate catchment tray.

Place a sheet of paper over the burner, see diagram 12.6.

Clean the primary heat exchanger, with a suitable soft brush,

see diagram 12.6.

Brush from back to front NOT left to right.

Do not use a brush with metallic bristles.

Remove the paper and any debris.

12.2 Burner

Clean the fins of the burner with a suitable soft brush, any debris

can be allowed to fall into the mixing chamber.

Do not use a brush with metallic bristles.

Note: The burner is water cooled and a system drain down is

required if removing.