Instructions for use – Glow-worm EnergySaver 80 User Manual

Page 4

4

221837B

Instructions for Use

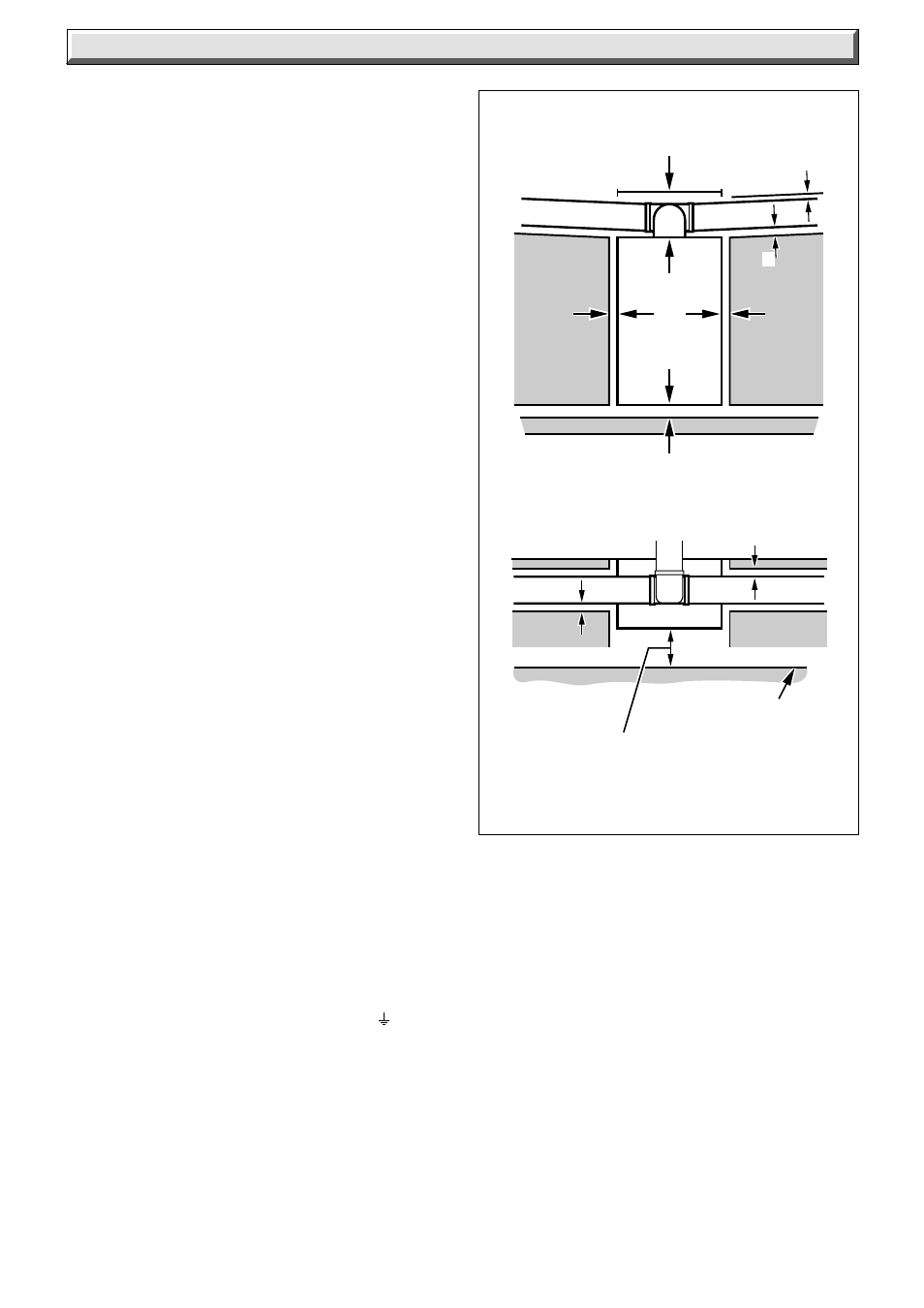

Boiler Clearances

If fixtures are positioned close to the boiler, space must be left

as shown in diagram 3. Enough space must also be left in front

of the boiler to allow for servicing.

Boilers Installed in a Compartment or

Cupboard

If the boiler is installed in a cupboard or compartment do not

obstruct any ventilation openings.

Do not use the cupboard or compartment for storage.

Regularly make sure that the air vent openings are clear of

obstructions.

Cleaning

WARNING. This appliance contains metal parts (components)

and care should be taken when handling and cleaning, with

particular regard to edges.

Clean the casing occasionally by wiping it over with a damp

soapy cloth or dry polishing duster.

Do not use an abrasive cleaner.

Protection Against Freezing

If the boiler is to be out of use for any long period of time during

severe weather conditions we recommend that the whole of the

system, including the boiler, be drained off to avoid the risk of

freezing up. Make sure that, if fitted, the immersion heater in the

cylinder is switched off.

If you have a sealed water system contact your installation/

servicing company as draining, refilling and pressurising must

be carried out by a competent person.

Boiler Electrical Supply

WARNING. The boiler must be earthed.

The boiler must only be connected to a 240V~50Hz supply,

protected by a 3A fuse.

All wiring must be in accordance with the current issue of

BS7671.

The colours of three core flexible cable are:

Brown - live, Blue - neutral, green and yellow - earth.

As the markings on your plug may not correspond with these

colours, continue as follows:

The wire coloured blue must be connected to the terminal

marked “N” or “Black”.

The wire coloured brown must be connected to the terminal

marked “R” or “Red”.

The wire coloured green and yellow must be connected to the

terminal marked “E”, “Green” or the earth symbol

.

Electrical Supply Failure

Failure of the electrical supply will cause the burner to go out.

Should this happen, operation of the boiler will normally resume

after the electrical supply is restored.

If the burner does not relight after an electrical supply failure the

overheat device may need resetting, press the reset button on

the underside of the boiler, see diagram 2.

Diagram 3

PERMANENT

SURFACE

*

5

*

5

5

5

150

100

500

*

INCREASE THIS DIMENSION TO

25mm FROM COMBUSTIBLE MATERIAL

CLEARANCE OPPOSITE TO FLUE EXIT

MUST BE ADEQUATE FOR THE

INTERNAL INSTALLATION

0157M

5

*

5