6 installation preparation, 2 wall template, 3 flue hole cutting – Glow-worm 18-30sxi Range User Manual

Page 18: 4 fixing jig and hanging bracket fixing

18

0020008155A

6 Installation Preparation

130

130

16

127

2.5

°

2.5°

Diagram 6.2

12075

WALL

TEMPLATE

EXTENDED SIDE FLUE

Ø 125

90

0

176

6.2 Wall Template

Remove the wall template from the wall mounting pack and

place in the desired position on a flat wall, giving due consideration

to boiler clearances, see section 2.2, and the flue you are fitting.

6.3 Flue Hole Cutting

The standard horizontal flues are designed with an internal

fall of 44mm/metre towards the boiler for disposal of condensate.

If the standard flue length alone is being used then the flue hole

of diameter 105mm can be cut in the position marked on the wall

template.

For standard side flues the horizontal flue centre line on the

wall template should be extended to the side wall, and the

vertical centre of the flue hole marked at 176mm from the back

wall.

For installations with external access, a 105mm diameter core

drill can be used.

For installations with internal access only, a 125mm diameter

core should be used.

When using extension pipes with the horizontal rear flue, a core

drill size of 125mm should be used to allow the extension pieces

to slope at 44mm/metre (2.5

o

) towards the boiler.

For extended side flues the flue hole centre should be

determined by extending the dashed inclined line on the template

to the side wall. This dashed line is drawn at 44mm/metre (2.5

o

)

rise from the boiler. Where this line reaches the side wall, a

horizontal line should be marked. The vertical centre line of the

flue should then be marked at 176mm from the back wall, see

diagram 6.2.

To allow for the flue passing through the wall at this angle a

125mm hole should be drilled irrespective of internal or external

installation.

If necessary remove the wall template whilst drilling the flue

hole.

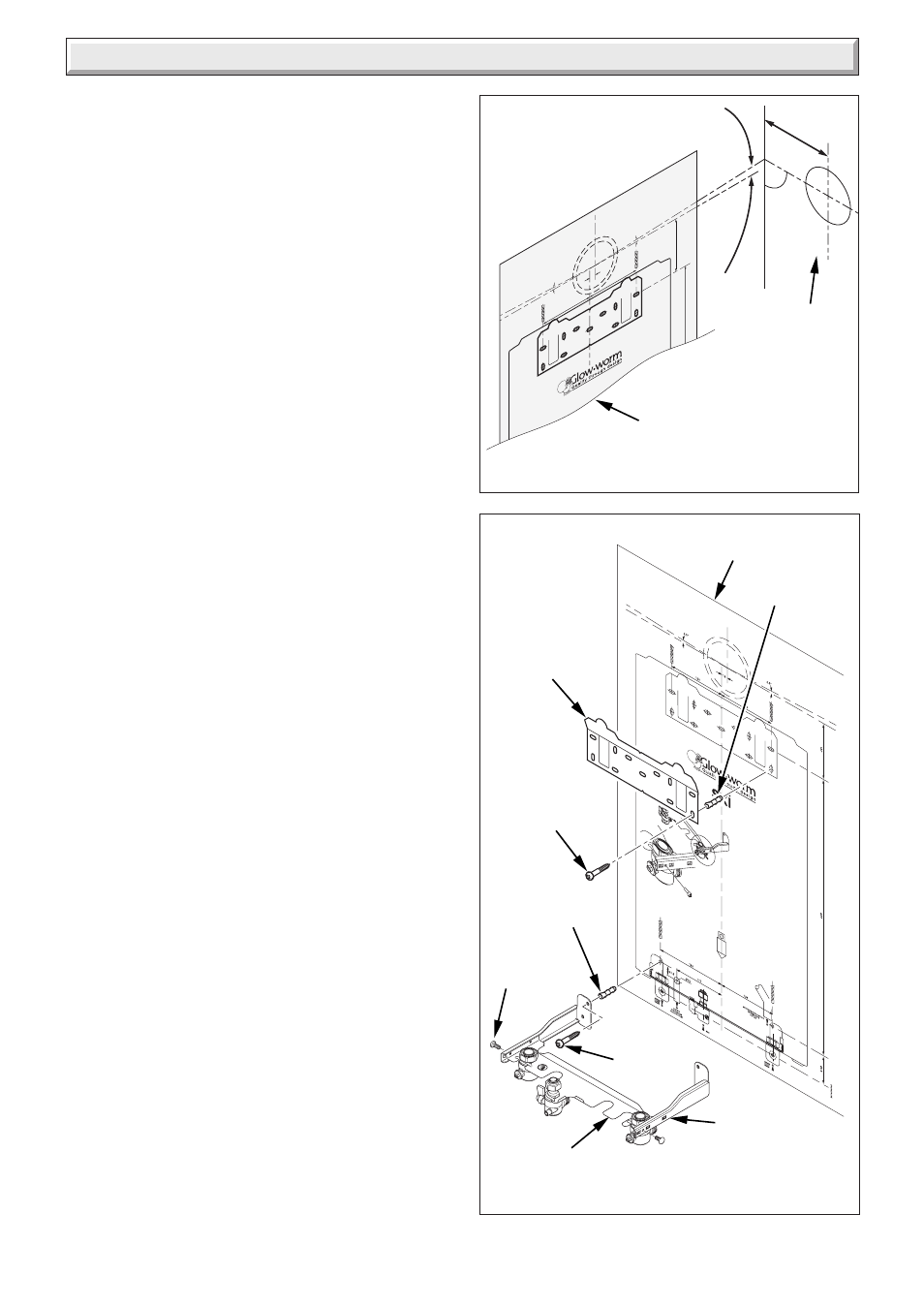

6.4 Fixing Jig and Hanging Bracket Fixing

Reposition the wall template over the flue hole and mark the

position of the fixing holes for the jig and the hanging bracket,

see diagram 6.3.

Drill the four fixing holes, 2 for the hanging bracket and 1 each

for the top hole of the fixing jig wall brackets and insert suitable

wall plugs.

If gas and/or water pipes are to be connected through the rear

wall, the holes must be drilled as marked on the wall template

prior to securing the fixing jig.

Secure the fixing jig wall brackets to the wall using suitable

screws.

NOTE: Due to the varied site conditions we do not supply

fixings and advise that the installer should supply those which

are suitable.

Locate the jig plate between the wall brackets and secure with

the No. 8 self tapping fixing screws supplied in the fittings pack.

Diagram 6.3

12050

WALL

PLUG

SCREW

WALL

TEMPLATE

HANGING

BRACKET

FIXING JIG

PLATE

FIXING

JIG WALL

BRACKETS

(2 OFF)

(Handed as shown)

SCREW

(2 OFF)

SCREW

WALL

PLUG