ENMET OMNI-4000 User Manual

Page 19

OMNI-4000 S/N 6705 and above

ENMET Corporation

13

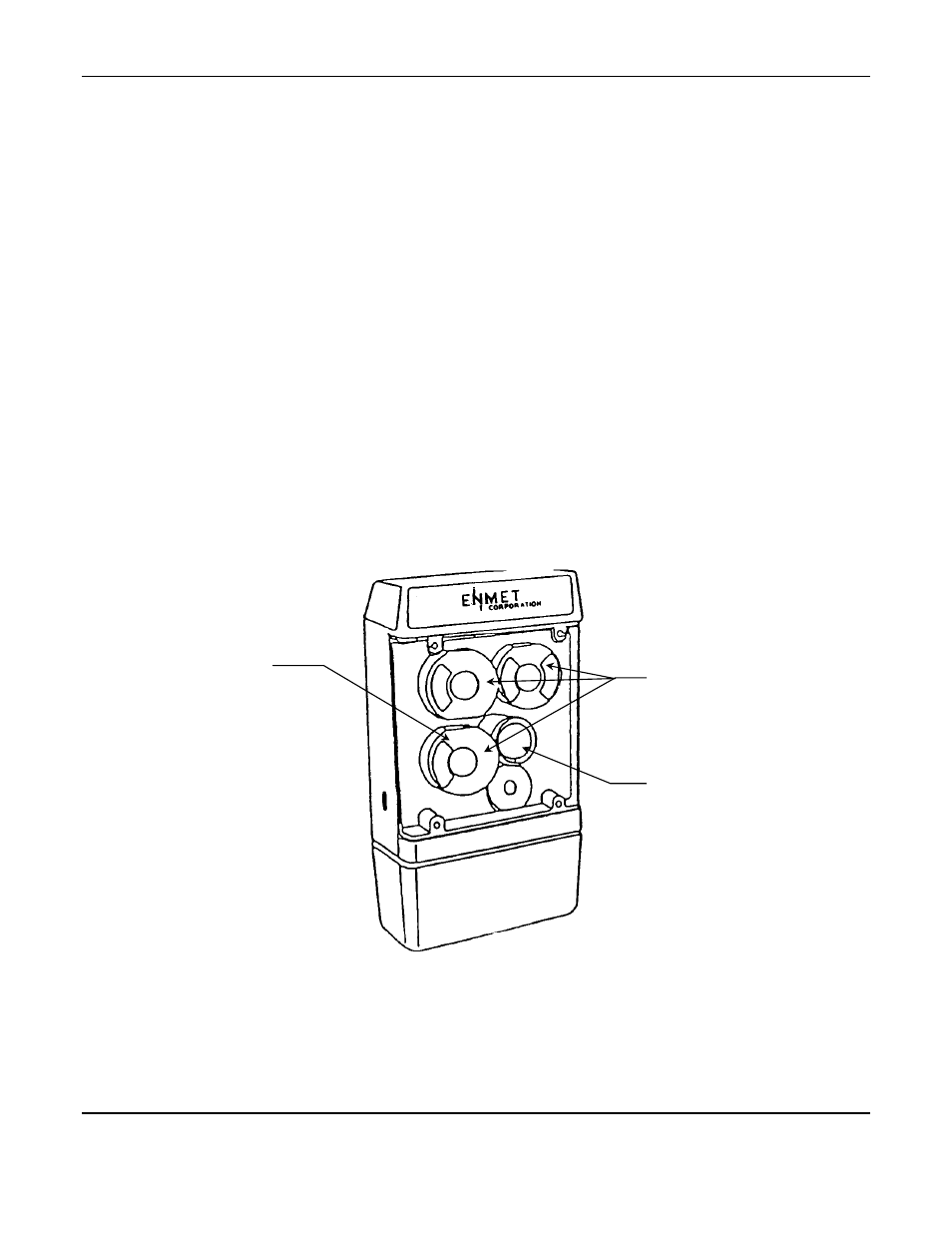

1.12 Smart Block Sensor Assemblies

These sensor assemblies for the OMNI-4000 must be handled with extreme care. Impact, excess temperatures or

penetration of water can negatively affect the readings or in extreme cases destroy the sensors. See Figure 1-17 for

sensor locations.

The toxic, CO2, BRH and oxygen smart block sensor assemblies contain electronic components. One of these

components is a memory (EEPROM) in which the manufacturer has stored the characteristics of the sensor: reading

range, sundry corrective coefficients, TWA and STEL alarms, date of manufacture, serial number, etc. Also, "rate of

wear" information enables the OMNI-4000 to automatically signal the optimum moment for the replacement of a

sensor assembly.

No calibration adjustments are necessary to enact a change of smart block sensors from one gas to another. In the

interest of safety, we recommend a test with gas to check its correct operation - it is possible that the sensor was

damaged in transit and is not sensitive enough, and this can only be assessed with a gas check.

1.13 Intrinsic Safety

The OMNI-4000 has been tested and approved for intrinsic safety, which allows it to be used in hazardous

atmospheres. Opening of the instrument enclosure in a hazardous area is not allowed. The OMNI-4000 has been

passed EEX ia llc T4.

The OMNI-4000 has also been tested and certified by the Canadian Standards Association to CSA Standard C22.2

No. 152-M1984, Combustible Gas Detection Instruments. Under this standard, the performance of the combustible

gas detection channel, only is evaluated.

Figure 1-17 Sensor locations Inside the Instrument

Explosive Gas

Sensor

CO2 Sensor

(if needed)

Toxic Gas or

Oxygen Sensor

Locations