Carburetor adjustment, Brake adjustment (see figure 16), Lubrication – Bolens TMO-3394704 User Manual

Page 14: Steering gears, Steering shaft, Transaxle, Wheels, Pivot pdints, Maintenance, Lubrication maintenance

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

(1/8" less than A)

FIGURE 15.

Brake

Lever

Cotter Pin

Axle'i

Housing

FIGURE 16.

CARBURETOR ADJUSTMENT

A

WARNING: If any adjustments are made

to the engine while the engine is running

(e.g.

carburetor),

disengage

all

clutches

and

blades.

Keep

clear

of

all

moving

parts. Be careful of heated surfaces and

muffler.

Minor

carburetor

adjustment

may

be

required

to

compensate

for

differences

in

fuel,

temperature,

altitude and load.

To adjust the carburetor, refer to

the separate engine manual packed with your unit.

NOTE: A dirty air cleaner will cause an engine to run

rough. Be certain air cleaner is clean and attached to

the carburetor before adjusting carburetor.

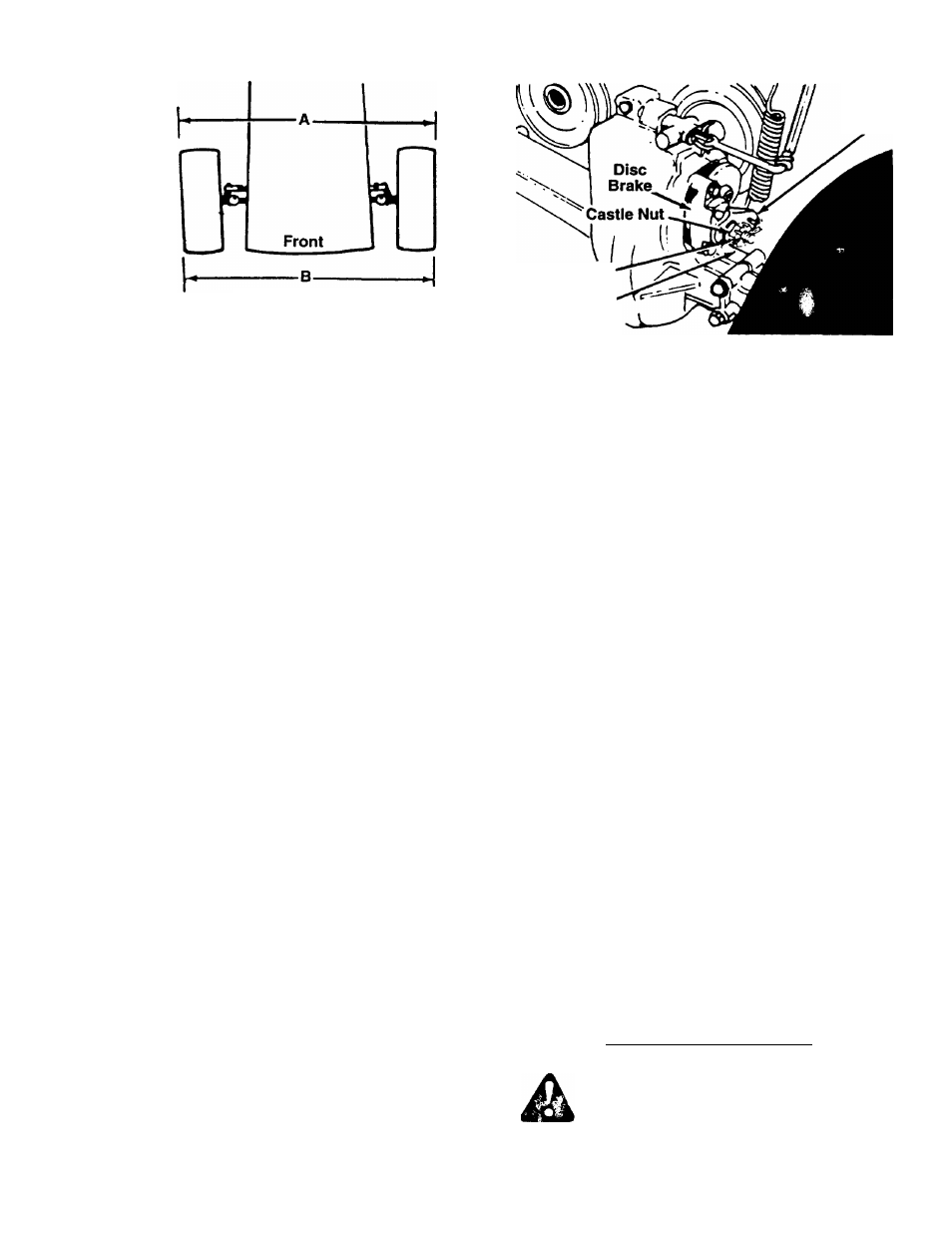

BRAKE ADJUSTMENT

(See figure 16)

The brake is located by the left rear wheel inside the

frame. During normal operation of this machine, the

brake is subject to wear and will require periodic

examination and adjustment.

A

WARNING: Do not have the engine run

ning when you adjurt the brake.

NOTE: Y o ' r b'ake

may

be eq pped with a

!

g

J<

nut

instead nf the castle nut and cotter pin shown in *igure

1C.

To aojust the brake, remove the cotter pin from the

castle nut (if so equipped). Adjust the nut so the brake

starts to engage when the brake lever is 1/4" to 5/16"

av/ay from the axle housing.

NOTE: Figure 1C is shown with the unit tipped up on

rear wheels for clarity only.

LUBRICATION

A

WARNING: Always stop engine and dis

connect spark plug wire before cleaning,

lubricating or doing any kind of work on

lawn tractor.

STEERING GEARS

Lubricate teeth of steering gears with automotive

multi-purpose grease after every 25 hours of opera

tion or once a season.

STEERING SHAFT

Lubricate steering shaft at least once a season with

light oil.

TRANSAXLE

The transaxle is lubricated and sealed at the factory

and does not require checking. If disassembled for

any reason, lubricate with 10 oz. of grease, part num

ber 737-0148.

WHEELS

The front wheels are provided with grease fittings.

The rear wheels must be removed from the axle for

lubrication. Lubricate both front and rear wheels at

least once a season with automotive multi-purpose

grease.

PIVOT PDINTS

Lubricate all pivot poiri.i. with iigfit oil at least once a

season.

MAINTENANCE

WARNING:

Disconnect

the

spark

plug

wire

and

ground

against

the

engine

before performing

any

ivpairs or mainte

nance.

14