Bard Bayrd Furnace 403293A User Manual

Page 67

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

4.

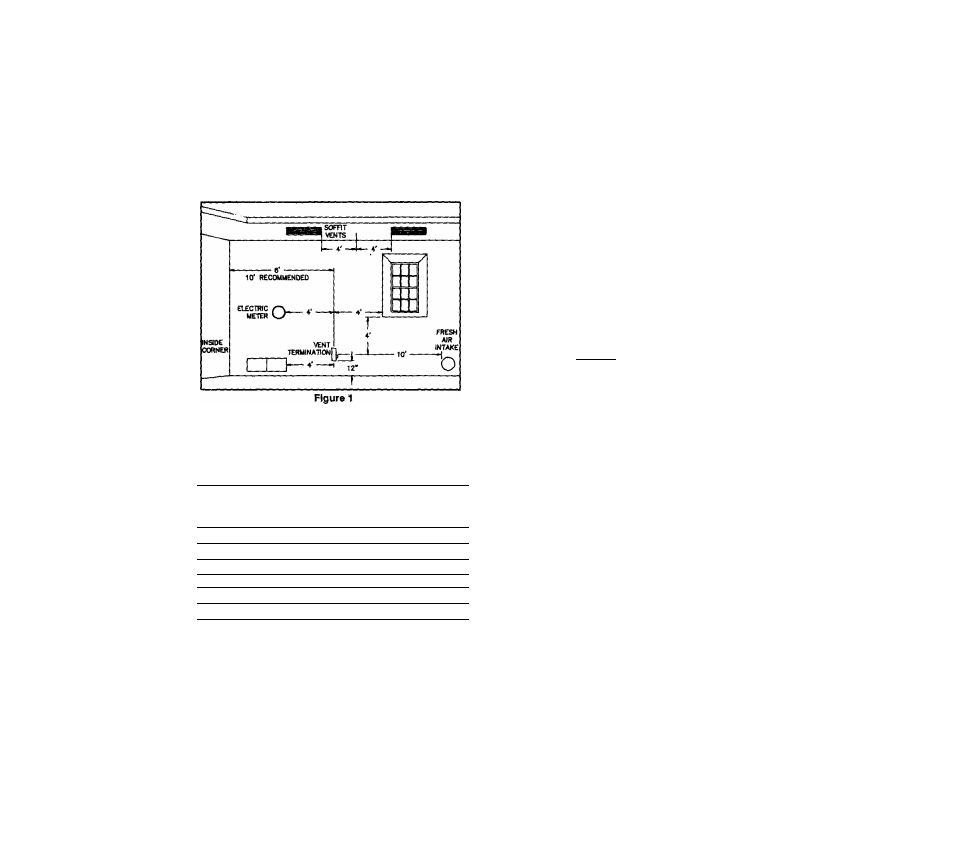

At (east 6 feet from any inside corner formed

by two exterior wails. 10 feet is desirable.

5.

At least 4 feet horizontally and vertically from

any soffit or under save vent.

6.

At least 3 feet above or 10 feet from any

forced air inlet to the building.

7.

At lezist 10 feet from any adjacent building.

8.

At least 4 feet from plants or shrubbery.

6. See below for allowable vent lengths and vent pipe

sizes.

Furnace

Input

BTUH

Vent

Pipe Size

Maximum

Lengths & Elbows

40,000

3 inch

40 ft.

& 4 elbows

60,000

4 inch

40 ft.

& 4 elbows

80,000

4 inch

40 ft. & 4 elbows

100,000

4 inch

40 ft. & 4 elbows

120,000

4 inch

40 ft. & 4 elbows

140,l,"0

4 inch

40 ft.

& 4 elbows

NOTE: A minimum vent length of 48 inches is necessary

for furnace service access.

C. V*nl Pipe Inslallatlon

1. Cutting

Cut pipe with a handsaw containing at least 24

teeth per inch. Cut pipe squarely.

WARNING«

FAILURE

TO

CUT

PIPE

SQUARELY COULD RESULT IN PIPE NOT

SEAUNG PROPERLY, THIS COULD ALLOW

COMBUSTION PRODUCTS TO COLLECT IN

STRUCTURE DURING USE, RESULTING IN

INJURY OR DEATH.

WARNING«

DO

NOT

DRILL

HOLES

IN

PLASTIC PIPE OR FITTINGS. DO NOT USE

SHEET METAL SCREWS. RIVETS OR LOCK

ING CLIPS IN PIPE OR FITTINGS. DRILLING,

USING SCREWS OR RIVETS MAY CAUSE

PIPE OR FITTINGS TO CRACK, ALLOWING

COMBUSTION PRODUCTS TO COLLECT IN

STRUCTURE DURING USE, RESULTING IN

INJURY OR DEATH.

NOTE: Do not cut pipe with a power saw. Cub

ting pipe with a power saw may cause

cracking or shattering of pipe. Cracking

or shattering pipe may prevent a com

plete sea) when joining pipe,

2. Joining and Sealant

Use only approved sealant, Dow-Corning RTV-

736.

WARNING«

USE ONLY APPROVED SEAL

ANT, DO NOT USE PVC CEMENT. FAILURE

TO SEAL VENT SYSTEM WITH PROPER

SEALANT AND PROCEDURE COULD ALLOW

COMBUSTION PRODUCTS TO COLLECT IN

STRUCTURE DURING USE, RESULTING IN

INJURY OR DEATH.

NOTE: Be sure pipe and fitting surfaces are

clean and free of any oils, greases or dirt

that could adversely affect the pipe seal.

a.

Apply a 1/4 inch thick bead of eqaproved

sealant within 1/8 Inch of male pipe end.

Apply entirely around outside of male pipe.

b.

Push pipe and fitting completely together in

a twisting motion to help spread sealant.

c.

When pipe seats in the fitting, check that a

complete ring of sealant is visible. A complete

ring of sealant assures seal is gas-tight.

Sealant cures in 24 hours. Use foil tape to

hold joints together until cured, remove tape

after sealant cures.

NOTE: Vent system can be used before sealant

cures.

3. Vent Outlet Kit (4059400)

You must use vent outlet kit part number 4059400

when using high temperature plastic pipe on

models with inputs of 120,000 and 140,000 Btuh.

Vent outlet Kit 4059400 is only required on

models with inputs of 120,000 and 140,000 Btuh.

Vent outlet kit is required to convert oval vent

collar to round vent collar. Round vent collar will

make furnace compatible for use with 4 inch

diameter, high temperature plastic pipe.

65