Bard Bayrd Furnace 403293A User Manual

Page 26

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

■ВАСЖ OF nLTER CABINET

AND FURNACE CASING

SIDE OF niTER CABINET

AND FURNACE CASING-

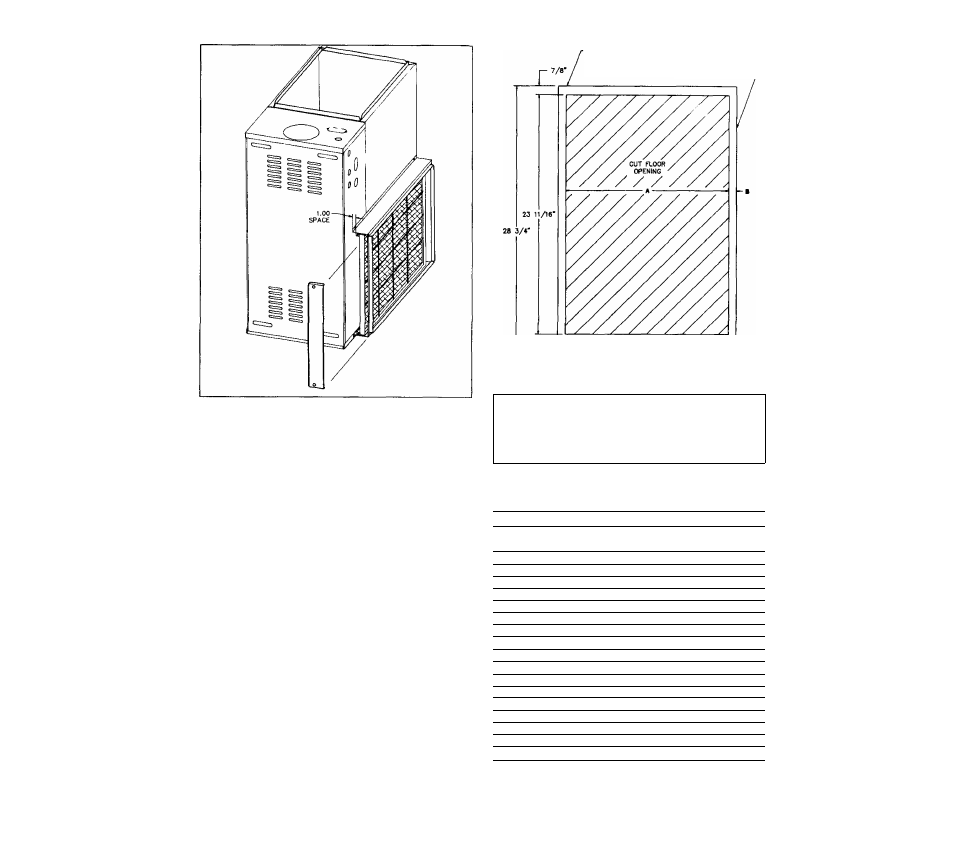

UPFLOW SIDE FILTER CABINET

FIGURE 29

1.

Upflow Positions.

a.

Upflow position uses a bottom filter cabinet, side fitter

cabinet or return air filter grille (field supplied).

Manufacturer available bottom and side filter cabi

nets provide correct fitter spacing to assure designed

airflow. Field fabricated filter cabinets should allow

1” spacing between filter and furnace.

b.

1. For upflow side return, use a 16x25 filter,

2.

For upflow air delivery above 1800 CFM use the

following combinations of return air openings;

1.

Bottom only or

2.

1 Side and Bottom or

3.

Both sides.

Use appropriate filter cabinets with combinations

listed above.

c.

See figures 30A and ЗОВ for floor cut out and filter

size of bottom filter cabinet available from manufac

turer.

FILTIR ОШ1МЕТ

A

13-1/16"

15-1/16"

19-1/16"

19-1/16"

в

c

23/32" 14-1/2"

1- 7^52’ 17-.1/2"

23/32" 20-1/2"

2- 7/32" 23-1/2"

UPFLOW FLOOR CUT OUT FOR

BOTTOM FILTER CABINET

FIGURE 30A

Bottom Return Filter Sizes

GAS INPUT

*BTU/HR

MOTOR

*H.P.

FILTER

SIZE

40,000

1/4

14

X

25

40,000

1/3

14x 25

60.000

1/4

14x 25

60,000

1/3

14x 25

60,000

1/2

16

X

25

80,000

1/4

14x 25

80,000

1/3

14x 25

80,000

1/2

1 6 x 2 5

80,000

3/4

20

X

25

100,000

1/3

16x 25

100,000

1/2

16

X

25

100,000

3/4

20x 25

120,000

1/2

20x 25

120,000

3/4

20x 25

140,000

3/4

20

X

25

140.000

3/4

20

X

25

‘See furnace rating plate located on blower door.

FIGURE ЗОВ

24