Table v — pilot gas gonsumptló^j – Bryant 396G User Manual

Page 5

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Whén thè pilot flame is established, pilot 6ÌÌ switches iiè

contacts in approximately 40 to 60 secohcis, energizing thè

main valve portion of gas valve 5F and deenergizing pilot

igniter 6F and the “pick” coil portion of the pilot solenoid in

gas valve 5F.

The main valve poirtibii of gas valve 5F is heat motor operated;

therefore, after approximately 10 seconds, (Robertshaw Valve

opens instantly), this portion of the valve opens, permitting

gas flow to the main burners where the gas in ignited by pilot

6H.

2. BDP 647 and Essex 242 iSas Valves

(Match-Lit Models)

The furnace pilot must bè lit. to energize the thermal

magnet circuit of gas valve 5E; thus permitting gas flow tb

thè remaining portion of the valve.

tABlE V — PILOT GAS GONSUMPTlÓ^J

......... Pilot

Gas

BtüH

In; wc

ËDP 733B

...... Nat

........ 875

.......... 5;0

Penri

Nat

1250

3.5

Penn

Prop.

690

10.5

Wheii thé thermostat “calls for heat;” the control circuit is

closed bet\veeh terminals R and W, Power froni transformer

ÍÁ through fusible link Í1C and limit sw;itches 7H1/7H2

energizes gas valve 5É, causing the valve tb Open ând per

mitting gas flow to thé main burners, wherè it is ignited bÿ

the pilot. Some furnaces af e equipped with a step opening gab

valve. When the burners first i^ite, the flame will be low and

soft. In approximately 15 seconds the valve will fully open and

the burner uamé will be normal size.

3. Essex 242 Gas Valve (HD Models) LPG

When the thermostat "calls for heat,” the control circuit is

closed betwëèü terminals R ând W. Power from transfofniër

l ihrotigh Rigibiê lüik íiC, limit switches 7HÍ & 7ÍÍÍ, âhd

through lockout tifhëf ínbdüle 6CÍ3, ëhergièës pilot igniter 8CÍ2

and the pilot valve part of gas valve 5F, causing the valve to

Open and to ignite the pilot. When the pilot flame is estab

lished, thë pilot Sensing probe energizes the main gas valve,

permitting gas flow, to thè main burners. The pilot electrode

continues sparking for approximately 5 to 10 seconds after the

pilot flame has beeii established.

If the pilot flamè iS not proven withiii approximately 30

seconds; lockout module 6G3 opens, deenèrgizing gaS valve 5F

and stopping thé gas flo\v to thë pilot; The. lockout module

remains Open until it is manually reset bÿ interrupting thé

low-voltagé or high-voltage circuit for approximately 30

Seconds.

3. Blower Circuit

With power through thé solid-state time-delay circuit on

printed-circuit board 6C1 and heat relay 2A; blower motor

3

d

is energized on heating speed approximately 75 seconds

after gas valve 5E has been energized (or the pilot flame haS

been proven in the case of BDP 646 Gas Valve 5F).

4; Limit Control

If the furnace overheats for any reason, limit control 7H1

switches; breaking the circuit to automatic gas valve 5E or

5F. The gas valve closes immediately, stopping gas flow to

the main burners and the pilot. In addition; blower motor 3D

continues to operate because heat relay 2A is deenergized to

cool down the furnace.

Manual reset auxiliary limit switch 7H2 is located on the

top right-hand corner df the furnace. In the event of blower

motor failure, this switch breaks the electrical circuit to the

gas valve, stopping gas flow to the main burners; The switch

must be manually reset after the blower motor has been rè^

placed.

Fusible link iiC is provided in the transformer ÌA secondary

Circuit as protection from overheating Conditions in the

vestibule area of the fumacè. Should this condition exist,

the fuse opens and deenergizes gas valve 5E or 5F and heat

relay 2A, stopping the gas flow to the burners and starting

blower motor 3D.

When the therrhostat is satisfied, the circuit between R and

W is broken, deenergizing automatic gas valve 5E or 5F,

pilot 6H (when used), and the solid-state time-delay circuit

on printed-circuit board 6C1. The gas flow stops immediately

to the pilot and rtiain burners with the BDP 646 or Robertshaw

7000 BKER Gas Valves, and to the main burners only with the

BDP 647 and Essex 242 Gas Valves. After approximately 105

seconds, heat relay 2A is energized and blower motor 3D stops.

Somé furnaces are equipped with a step opening gas valve.

When the burners first ignite, the flame will be low and soft.

In approximately Ì5 seconds, the valve will fully open and the

burner flame will be nOrmâl size.

B. Vent Damper (when used)

When the thermostat “calls for heat,” the control circuit is

closed between terminals R and

W.

Power from transformer

lA energizes the damper motor relay coil, causing the nor

mally closed relay contacts to open, deenergizing the

damper motor and causing the spring-loaded damper to

open. When thé automatic vent damper is open, the circuit is

completed to automatic gas valve 5E or 5F. The sequence

from this point on is the same as that for heating.

When the thermostat is satisfied, the circuit between R and

W is broken, deenegizing the damper motor relay, and caus

ing the relay contacts to close. The daiiiper motor starts and

closes the damper.

C. Cooling (cooling models only)

When the thermostat “calls for cooling,” power from trans

former lA energizes thé condensing Unit cOntâctbr, Cooling

relay coil

2F,

Closiiig its contacts and èhêrgizing blower mo

tor 3Î3 Oh its cooling Speed, it continues tO operate until thé

thermostat is satisfied.

When the thermostat is satisfied, the circuit to terminal Gc

is broken, deenergizing cooling relay coil 2F which, in turn,

opens its contacts, stopping blower motor 3D.

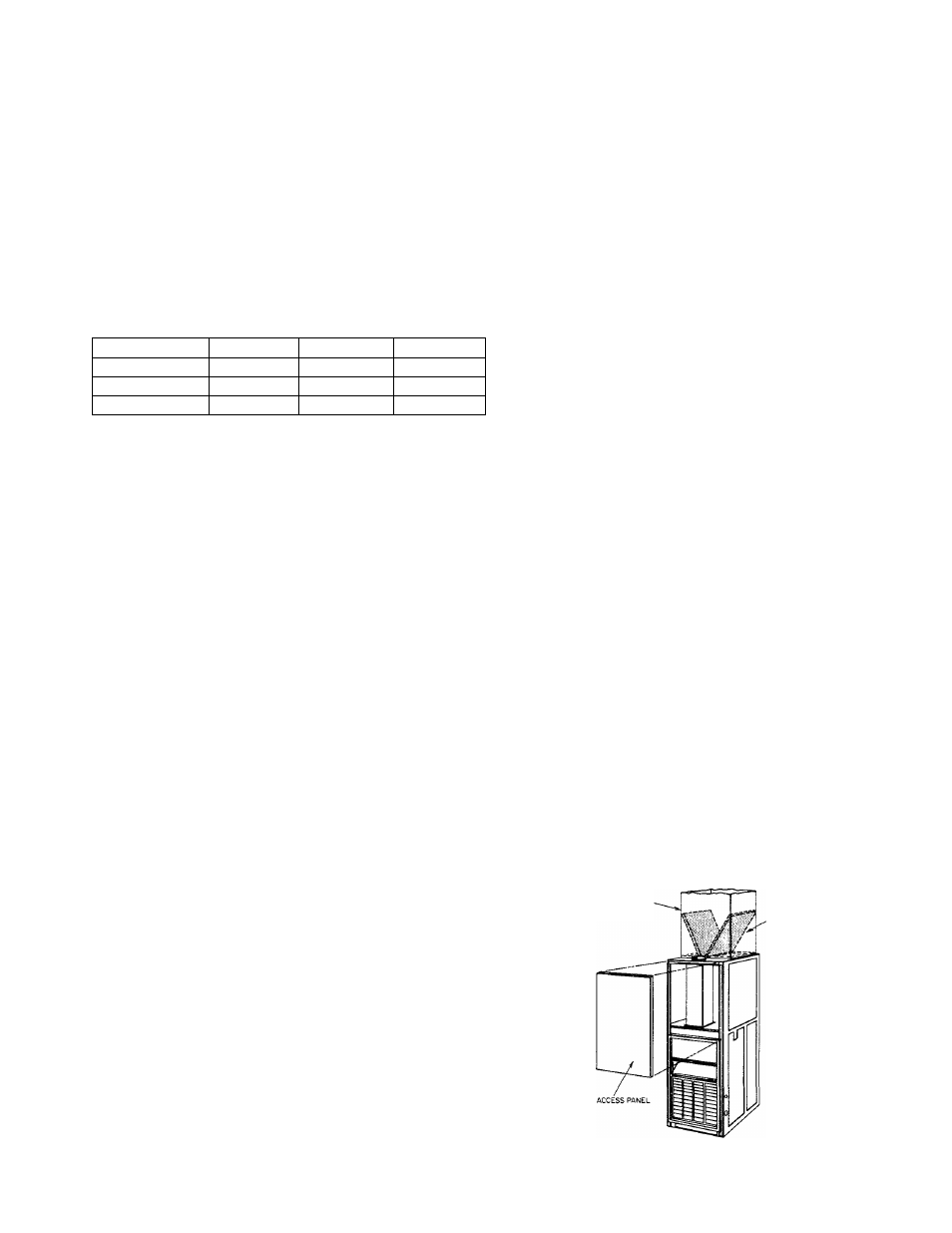

Vili. FILTER ARRANGEMENT

The two factory-supplied filters are shipped in the blower

compartment. After the return-air duct has been connected

to

the

fiurnace, install the filters in a V-formation inside the

return air plenum. See Figure 12.

WARNING:

Never operate unit without a filter or v/ith filter

access door removed.

RETURN-AIR

PLENUM

INSTALLATION

POSITION

(DF FILTERS

Figure 12—Position of Filters