Figure 20, Seat maintenance, Battery service – Ariens 935000 User Manual

Page 13: Tires pressures - table 1

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

To

avoid

overheating

and

possible

engine

damage,

periodically remove

the shrouding from

around the cooling fins. Figure 16, and clean the

area shown within the heavy black line of all

grass,dirt or chaff accumulation.

KEEP

AREAS

WITHIN

HEAVY LINES CLEAR

OF ALL DEBRIS

FIGURE 20

SEAT MAINTENANCE

Clean the seat regularly, using a vinyl cleaner (not a sol

vent.)

Extreme

temperatures

can

damage

the

seat

when left without protection against the weather. If the

seat should tear, apply vihyl repair tape to the damaged

area.

BATTERY SERVICE

NOTE:

REFER

TO

"BATTERY

SET-UP

AND

MAINTENANCE” SECTION, PAGE 36.

1.

Check

the battery electrolyte

level once each

week or every 25 hours of operation. Check it

monthly if the tractor is idle or is in storage. Add

distilled water to bring the level to the bottom of

the split ring in the filler tube of each cell.

2.

Each spring and fall clean the battery and ter

minals with ammonia or bicarbonate of soda solu

tion followed by flushing with clean water. Keep

ing

the

battery

clean

will

prolong

battery

life.

After cleaning, apply a light coat of grease to the

terminal and cable ends.

3.

Keep cable clamps securely tightened to terminals

and keep battery hold-down clamps tight to pre

vent vibration. Do not overtighten clamps. This

could warp the case.

WARNING;

STORAGE

BATTERIES

GIVE

OFF

HIGHLY

INFLAMMABLE

HYDROGEN

GAS.

DO

NOT

ALLOW

SPARKS OR FLAME NEAR BATTERY. DO NOT LAY

TOOLS

ACROSS

BATTERY

TERMINALS

WHICH

MAY

CAUSE A SPARK RESULTING IN AN EXPLOSION.

4.

Maintain the battery at full charge during storage

and during the winter months to prevent freezing.

When water is added during freezing weather, run

the engine at least on hour to bring the battery up

to a full state of charge.

5.

When

installing

the

battery,

make

certain

the

ground cable is connected to the negative(-) ter

minal on battery. See Figure 22. Be sure positive

cable is connected to positive

{+)

terminal.

TIRES PRESSURES - TABLE 1

Check tires pressures at least once each month. Inflate

tires to pressures shown using a low pressure tire

gauge for accurate readings. Keep tires properly in

flated at all times. Over-inflation will cause operator

discomfort.

Under-inflation

will

cause

short

tire

life.

Make sure the tire valve caps are in place.

TIRE SIZE

LOADING

Ught

Medium

Heavy

Front

(Lawn Work)

(Sno-Thro)

13

X

5.00 - 6

8 psi

12 psi

16 psi

Rear

18

X

8.50 - 8

(Lawn Work)

6 psi

(Sno-Thro)

8 psi

10 psi

TABLE 1

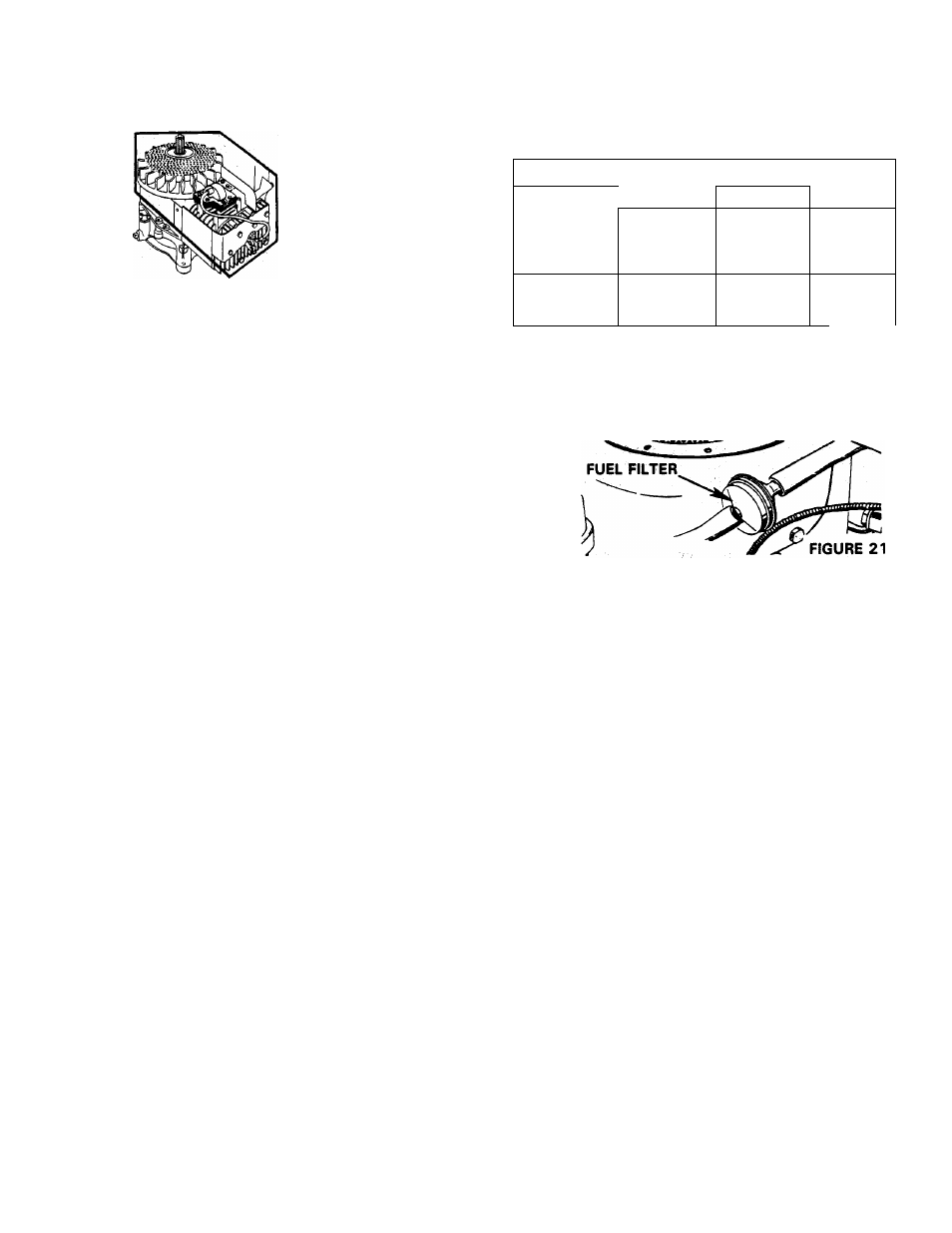

FUEL FILTER SERVICE - IFIGURE 21

Wheri dirt or other foreign material is allowed to enter

the fubi tank it will collect in the fuel filter eventually

causing fuel stoppage. If this occufs, replace filter.

MOWER BLADE AND VANES MAINTENANCE

Check tire pressure. Uneven tire pressure may cause

uneven grass cutting.

Models with 32” mowers are equipped with high lift

blades

standard.

Vanes

(Service

Part

No.

527011)

may be bolted to the blades to improve discharge and

bagging or collecting of grass. These vanes may or may

not be helpful depending on your type of grass and

cutting conditions.

Ariens

recommends

that

the

user

try

the

mower

without vanes first and if the performance is satisfac

tory, use without vanes since the vanes use more

power and generate more noise. Use vanes (Service

Part No. 52701 1) only if satisfactory performance can

not

be

obtained

without

them.

Generally,

broadleaf

grasses can be cut and bagged without vanes. The

finer grasses may require vanes. In extremely wet con

ditions, vanes may also be of help.

Routinely check for wear on the mower blade and

vanes, if used. This is especially true in sandy soil con

ditions.

CAUTION:

WEAR

OF

THE

MOWER

BLADE

CAN

CAUSE

STRUCTURAL

WEAKNESS.

DO

NOT

INSTALL

NEW OR REPLACEMENT VANES ON WORN BLADES.

THIS IS A POTENTIAL HAZARD.

Replace

worn

parts

with

Ariens

original

equipment,

blades, vanes, and Grade 8 hardware as specified. Cap

screws must be installed with heads on top of the

vanes and vanes on top of the blade.

13 -