Checking forward drive belt tension, A warning, Checking the reverse drive beit tension – Troy-Bilt 15009 User Manual

Page 41: Adjusting the forward drive belt tension, Adjusting forward drive belt tension, Warning

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Checking Forward Drive Belt Tension

A

WARNING

stop the engine, allow it to cool, disconnect

the spark plug wire and prevent it from

touching the spark plug, then remove the

Engine Ignition key before performing any

maintenance on your tiller.

Failure to follow these instructions could re

sult in personal injury or property damage.

This test for the correct tension on the forward

drive belt is the same check that you used when

adjusting the handlebar height.

Please refer to Section 3, Handlebar Height

Adjustment, for the correct procedures. If you get

the 3/16" to 5/16" gap that is mentioned in the

Handlebar Height Adjustment procedure, the

tension on the forward drive belt is correct.

If you are unable to get the 3/16" to 5/16" gap

when the lower end of the Forward Clutch Rod is

in the correct hole in the swivel plate, your belt

may be worn and you may have to make the

secondary adjustment to the forward drive belt

idler to take up slack. Please refer to “Adjusting

the Forward Drive Belt Tension” in this Section.

Checking the Reverse Drive Beit Tension

A

WARNING

stop the engine, allow it to cool, disconnect

the spark plug wire and prevent it from

touching the spark plug, then remove the

Engine Ignition key before performing any

maintenance on your tiller.

Failure to follow these instructions could re

sult in personal injury or property damage.

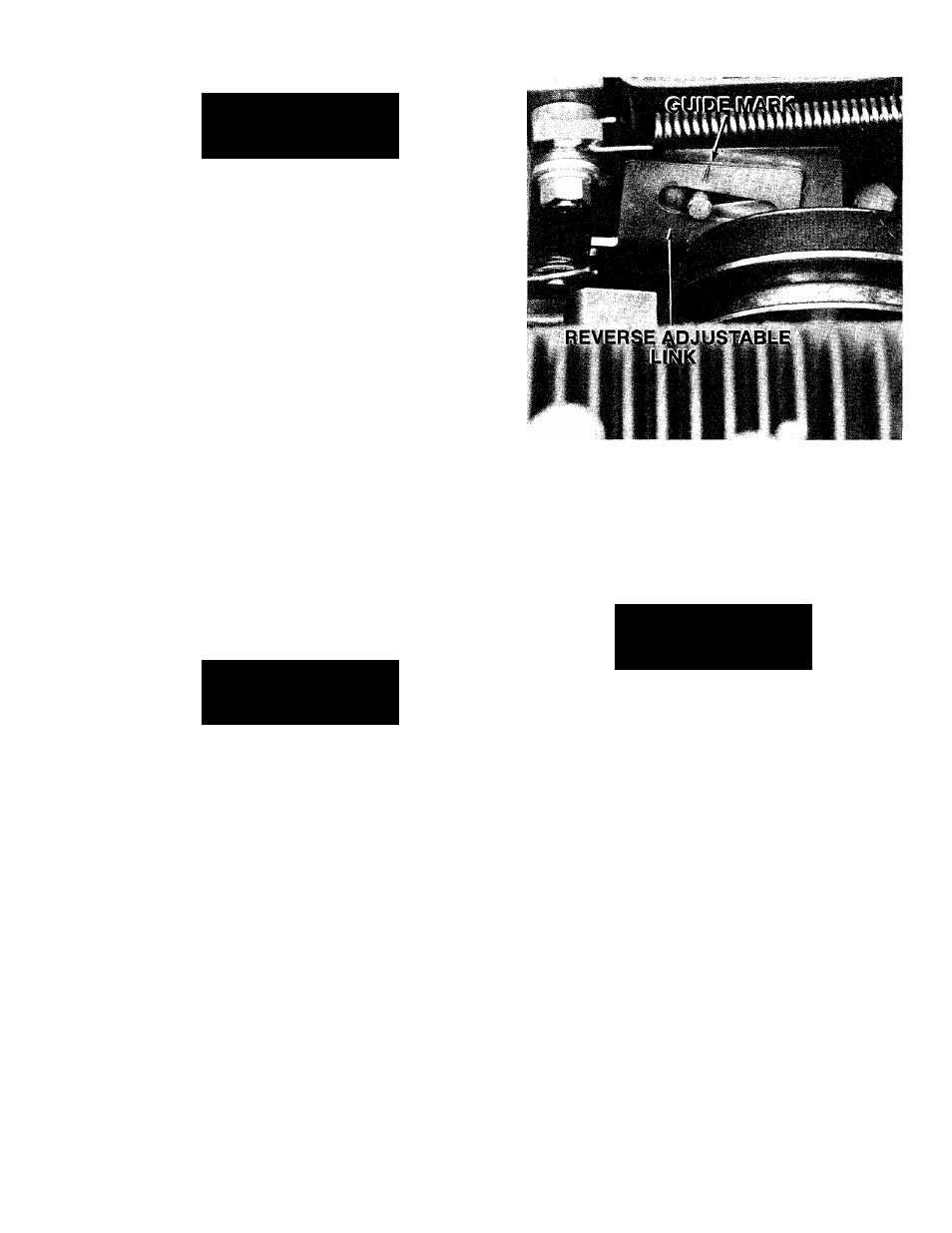

1. Remove the two nuts that secure the belt

cover to the tiller.

2. Position yourself at the front of the tiller and

use your left hand to push the reverse idler arm

inward as far as possible. While holding the arm

at this position, look at the position of the belt

tension guide mark on the reverse adjustable

link. See Photo 5-13.

3. The belt tension is correct if the guide mark is

anywhere to the left (as viewed from the front of

the tiller) of the pin. If the guide mark is aligned

with, or moves to the right side of the pin, then

the belt is too loose and it must be adjusted. See

“Adjusting Reverse Drive Belt Tension” in this

Section.

Photo 5-13: The guide mark on the Reverse

Adjustable Link (all models).

4. If the belt tension is correct, reinstall the belt

cover and secure it with the two nuts.

ADJUSTING

THE

FORWARD

DRIVE

BELT TENSION

A

WARNING

Stop the engine, allow it to cool, disconnect

the spark plug wire and prevent it from

touching the spark plug, then remove the

Engine ignition key before performing any

maintenance on your tiller.

Failure to follow these instructions could re

sult in personal injury or property damage.

To correctly adjust the tension on the forward

drive belt, you must first make certain that the

lower end of the Forward Clutch Lever is in the

correct hole in the swivel plate as described in

Section 3, Handlebar Height Adjustment.

If, after the handlebar height adjustment has

been performed, you are still unable to get the

3/16" to 5/16" gap as described in that proce

dure, you will have to make a secondary adjust

ment to compensate for the slack in the worn

belt. Do this as follows:

1. Remove the inner hairpin cotter from the lower

end of the Forward Clutch Rod.

2. Unscrew the Forward Clutch Rod (counter

clockwise as viewed from front of tiller) until the

threaded upper end of the Forward Clutch Rod

protrudes slightly above the rectangular nut in

the Forward Clutch bracket. See Photo 5-14.

39