Step 5: checking the transmission gear oil level – Troy-Bilt 15009 User Manual

Page 12

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

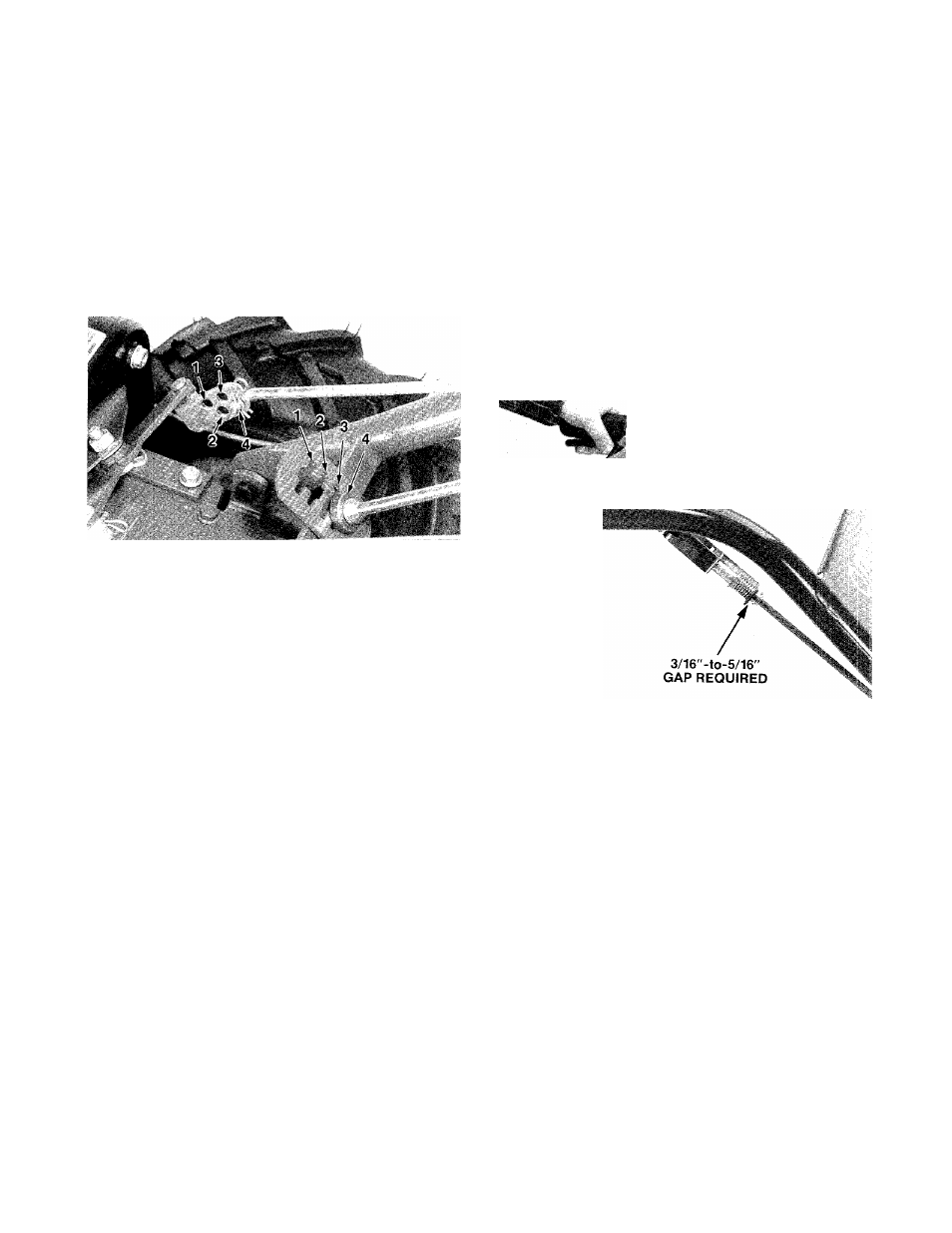

3. Note the four holes in the swivel plate on the

shifting mechanism.

The hole that you must in

sert the lower end of the Forward Clutch Rod

into depends upon which handlebar height

setting (on the curved handlebar height ad

justment bracket) you have the handiebars

set at.

Refer to Photo 2-10 to determine which

hole in the swivel plate to use. For example: if

you set the handlebar in slot number 1, then the

Forward Clutch Rod must be installed in hole

number 1 of the swivel plate.

.-'s»

Photo 2-10: Handlebar Height setting and Forward

Clutch Rod positioning are interrelated. They must

both be set in the same numbered positions.

4. Insert the lower end of the Forward Clutch

Rod into the proper hole in the swivel plate.

Secure it to the swivel plate by inserting a hairpin

cotter through the outer hole in the small bend of

the Forward Clutch Rod.

IMPORTANT

Whenever the handlebar height is changed,

the position of the Forward Clutch Rod must

be changed accordingly. Changing the han

dlebar height changes the tension on the

Forward Clutch Rod. This tension must be

adjusted by relocating the rod in the appro

priate hole in the clutch swivel plate.

To make sure the tension on the Forward

Clutch Rod (once connected) is correct:

a.

Stand on the right-hand side of the tiller

and pull the Forward Clutch Lever up and

hold it in place. See Photo 2-11.

b.

Check the gap between the “E-ring” and

the lower end of the bracket at the upper

end of the Forward Clutch Rod. Refer to

Photo 2-11.The gap should be 3/16"-to-

5/16". If you do not have a ruler handy, the

thickness of five pennies is approximately

5/16" thick.

c.

If the gap is incorrect, reverify that the

Forward Clutch Rod is located in the cor

rect hole in the swivel plate. If it isn’t, move

the lower end of the Forward Clutch Rod

into the correct hole and then check the

measurement gap again.

d.

To reset the gap distance properly, you

must make a simple adjustment to the

length of the Forward Clutch Rod. To do

this,disconnect it from the swivel plate,

then rotate it clockwise or counterclock

wise to shorten or lengthen the rod.

Reconnect it and measure the gap again

as shown below in Photo 2-11. Adjust the

length of the rod until the gap is within

3/16" to 5/16".

Photo 2-11: Carefully measure the gap between the

Forward Clutch Bracket and the “E-Ring. ”

STEP 5: CHECKING THE

TRANSMISSION GEAR OIL LEVEL

Once the handlebars are securely installed on

the tiller, move the tiller to a level area.

We have installed gear oil in the tiller trans

mission here at the Factory.

However, you

should make this very important check to be

sure that the gear oil level is still correct.

1. Make sure that your tiller is on a level area.

2. Lower the depth regulator lever to the second

notch to make sure that the transmission is as

level as possible. (See Photo 2-12.).

NOTE —

For shipping purposes, the depth regulator lever

might be secured with a plastic tie. If so, before the

depth regulator lever can be lowered, you must lift

the hood flap at the rear of the tiller and cut and re

move the tie.

10