Spark plug maintenance, Ignition system maintenance, Air cooling system maintenance – Troy-Bilt 15009 User Manual

Page 39: Awarning, Bold tines, Spark plug maintenance ignition system maintenance, Bolo tines, Warning

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Pony

(see Photo 5-9A)-clean (do not oil!) the

outer foam element every 10 hours; clean the

inner paper filter every 10 hours too, and replace

it every 50 hours.

Junior

(see Photo 5-9B)-replace the single

paper filter element after every 25 hours of en

gine operation. Do not clean it or oil it.

General Guidelines for servicing all model air

cleaner systems:

•

Before removing the outer air cleaner

cover, always remove any dirt or grease in

the Immediate vicinity—do not get dirt or

grease or any foreign materials in the carbu

retor!

• Inspect the foam pre-cleaner (if your model

comes with one) and the paper filter for signs

of excessive wear, tearing, or a loose fit.

• Wash the foam pre-cleaner only in a warm

water / liquid detergent mixture. Do not use

kerosene or mineral spirits as they could

damage the foam. Then rinse it in clear water

and squeeze until it is dry (don’t wring it out).

The Tecumseh 6HP foam pre-cleaner

should

be oiled. The Briggs & Stratton 5HP foam

pre-cleaner

should not

be oiled. (The Junior

Model’s Tecumseh engine does not have a

foam pre-cleaner.)

• Wipe the inside of the air cleaner cover and

the top of the air cleaner base plate with a

clean rag to remove dirt and grime. Don’t

knock dirt in the carburetor!

• Carefully install the foam pre-cleaner and

paper filter inner element, and the outer

cover with its hardware. The fit of these parts

must be secure and correct. All parts must be

reassembled as per the original assembly.

The performance of your engine is dependent

upon this.

NOTE—In very dusty or dirty conditions, in

spect and clean the fiiter(s) more often.

SPARK PLUG MAINTENANCE

NOTE:

Before you remove the spark plug,

brush or blow away debris from the top of

the cylinder head. This prevents debris from

accidentally falling into the spark plug hole.

Every fifty (50) hours of operation, remove the

spark plug and replace or clean it. If cleaning,

only scrape it—do not sandblast or wire brush it.

Reset the gap to .030". See engine literature.

IGNITION SYSTEM MAINTENANCE

Your tiller’s engine is equipped with electronic

ignition. It does not have either a condenser or

points. Therefore, you do not have to perform

any regular maintenance on this system other

than checking, cleaning, and adjusting (or re

placing) the spark plug as mentioned previously.

AIR COOLING SYSTEM

MAINTENANCE

Since your tiller operates in such a dusty envi

ronment, you should frequently check the en

gine’s cooling system for any type of obstruction.

Look between the engine cooling fins and the

engine air shrouds, and under the blower hous

ing for any trapped debris.

After the engine has cooled, use a screwdriver

or other tool to remove any trapped debris. Do

not remove the blower housing unless it is abso

lutely necessary.

A

warning

Failure to keep your engine’s cooling sys

tem clean will cause engine overheating

and will lead to engine damage.

BOLD TINES

Your tiller has bolo tines to more effectively

shred, chop, and bury the organic matter that

you are tilling back into your garden soil.

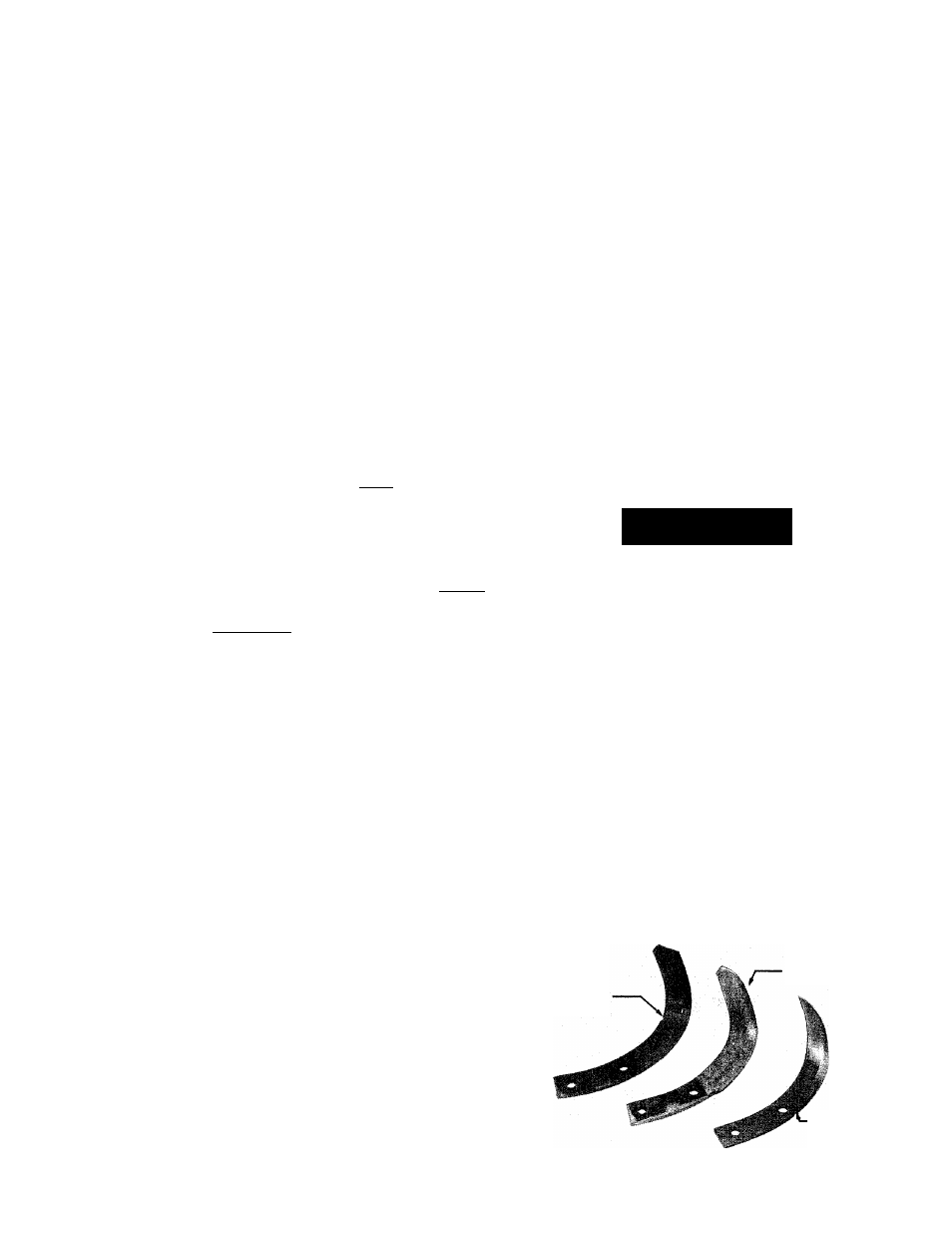

With use, these tines will become shorter, nar

rower, and pointed. When badly worn, they won’t

be able to turn over as much earth as new tines.

Compare your tines with those in Photo 5-10 if

you should notice a loss of tilling depth or poor

power composting. If your tines have become

too worn, you should replace them.

NEW

TINE

MODERATE

WEAR

REPLACE

Photo 5-10: Checking Bolo Tines for wear.

37