Caution, Sewing suggestions – SINGER 301 User Manual

Page 16

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

28

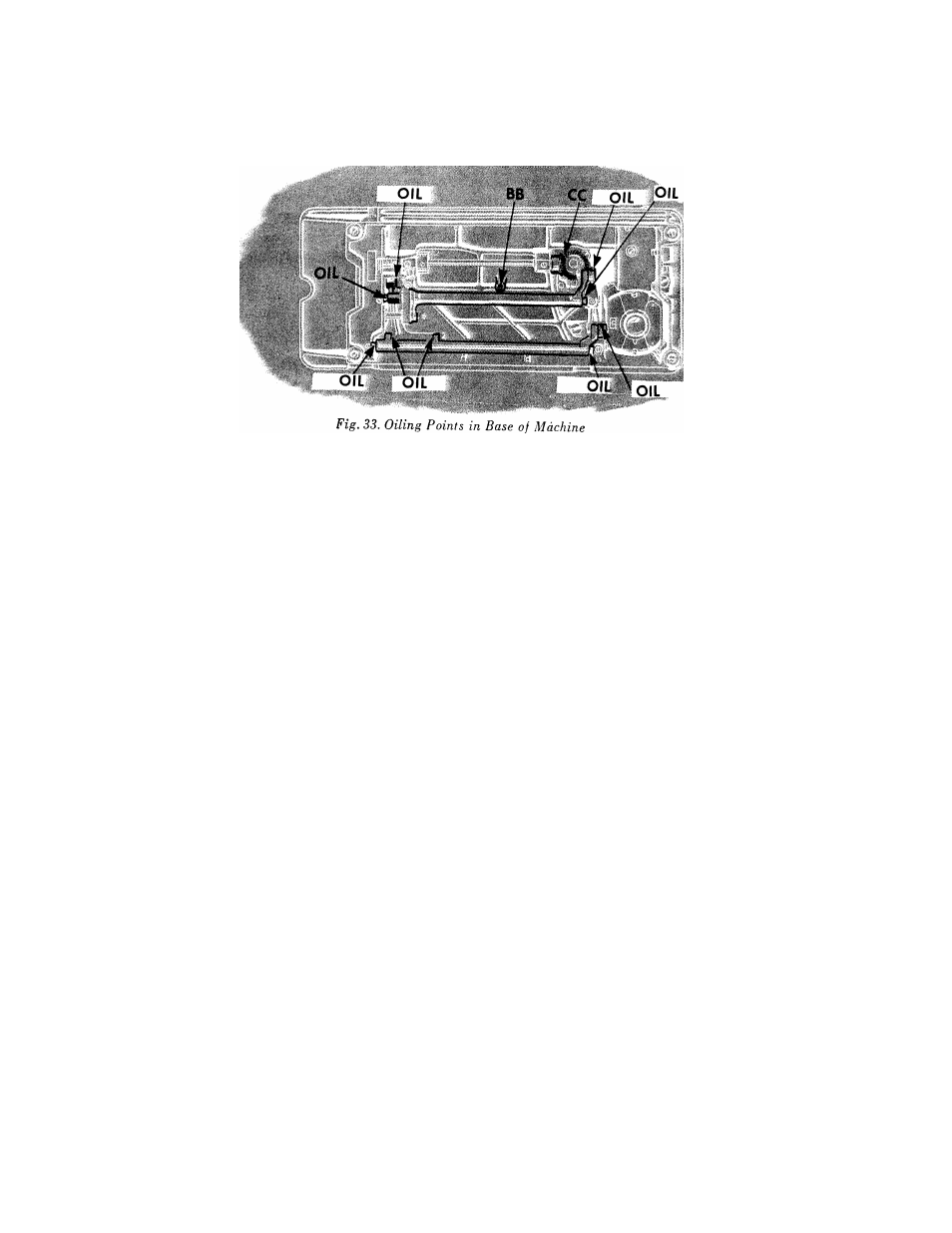

Remove machine from cabinet as instructed on

Page 6, and then turn machine over on its rear

side. Remove thumb nut from screw BB, Fig.

33 being careful not to lose felt washer, and

remove large cover from underside of bed. Oil

each of places indicated by arrows in Fig. 33,

and occasionally apply a small quantity of

lubricant to teeth of gears CC, then replace

cover and felt washer and fasten as before

with thumb nut (not too tightly).

C A U T I O N :

The motor requires no lubrication.

29

S E W I N G S U G G E S T I O N S

Breaking of Needles Might be Caused by:

1. Improper Size of Needle for Thread and

Material—See Page 70.

2. Needle Bent.

3. Pulling of Material when Stitching.

4. Needle Striking Improperly Fastened

Presser Foot or Attachments.

5. Crossing Too Thick Seams with Too Small

a Needle.

Breaking of Needle Thread Might be

Caused by:

1. A Knot in Thread.

2. Improper Threading—See Page 11.

3. Upper Tension Too Tight—See Page 21.

4. Needle not pushed up as far as it will go

into needle clamp—See Page 9.

5. Needle Blunt or Bent.

6. Thread Too Coarse for Needle—See

Page 70.

7. Roughened Hole in Throat Plate.

8. Improper Arrangement of Thread to Com

mence Sewing—See Page 16.

Breaking of Bobbin Thread Might be

Caused by:

1. Improper Threading of Bobbin Case—See

Page 14.

2. Bobbin Thread Tension Too Tight—See

Page 21.

Skipping of Stitches Might be Caused by:

1. Needle not pushed up as far as it will go

into needle clamp—See Page 9.

2. Needle Blunt or Bent.

3. Needle Too Small for Thread—See

Page 70.

If Machine Runs Heavily after standing

idle for a long period, apply a few drops of

kerosene at all oiling places, run machine for

a few minutes, then wipe clean and oil—See

Pages 26, 27 and 28.