To regulate bobbin thread tension, To remove and disassemble ne 4.e thread tension, To reassemble and replace needle thread tension – SINGER 301 User Manual

Page 11

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

21

T O R E G U L A T E N E E D L E T H R E A D T E N S I O N

The tension on needle thread can be tested

only when presser foot is down.

The numerals “0 to 9”

on dial D, Fig. 23 in

dicate different degrees

;y| of tension that can be

3o b t a i n e d. The num

bers do not denote size

of thread or ounces of

tension.

J

'T

•

When tension has been

NeedLe I firead 1 ension

,

correctly set as de

scribed on pages 23 and 24, note number at

indicator line G so that this setting may be

regained should the tension be altered for

special work.

To increase tension, turn thumb nut B

gradually to right (clockwise) until required

tension is obtained. Each higher number de

notes increased tension.

To decrease tension, turn thumb nut B

gradually to left (counter-clockwise) until re

quired tension is obtained. Each lower num

ber denotes less tension.

The tension indicator G is marked with the

signs -f- and —, which indicate the direction

in which to turn the thumb nut B for more

or less tension.

T O R E G U L A T E B O B B I N T H R E A D T E N S I O N

The tension on bobbin thread is regulated by

screw AA, Fig. 24 which is nearest center of

tension spring on outside of bobbin case. To

increase tension, turn screw AA over to right.

To decrease tension, turn

this screw over to left.

^

When tension on bobbin

thread has been once prop

erly adjusted, it is seldom

necessary to change it, as a

correct stitch can usually be

obtained by varying tension

on needle thread.

Fig. 24. Bobbin Thread Tension

22

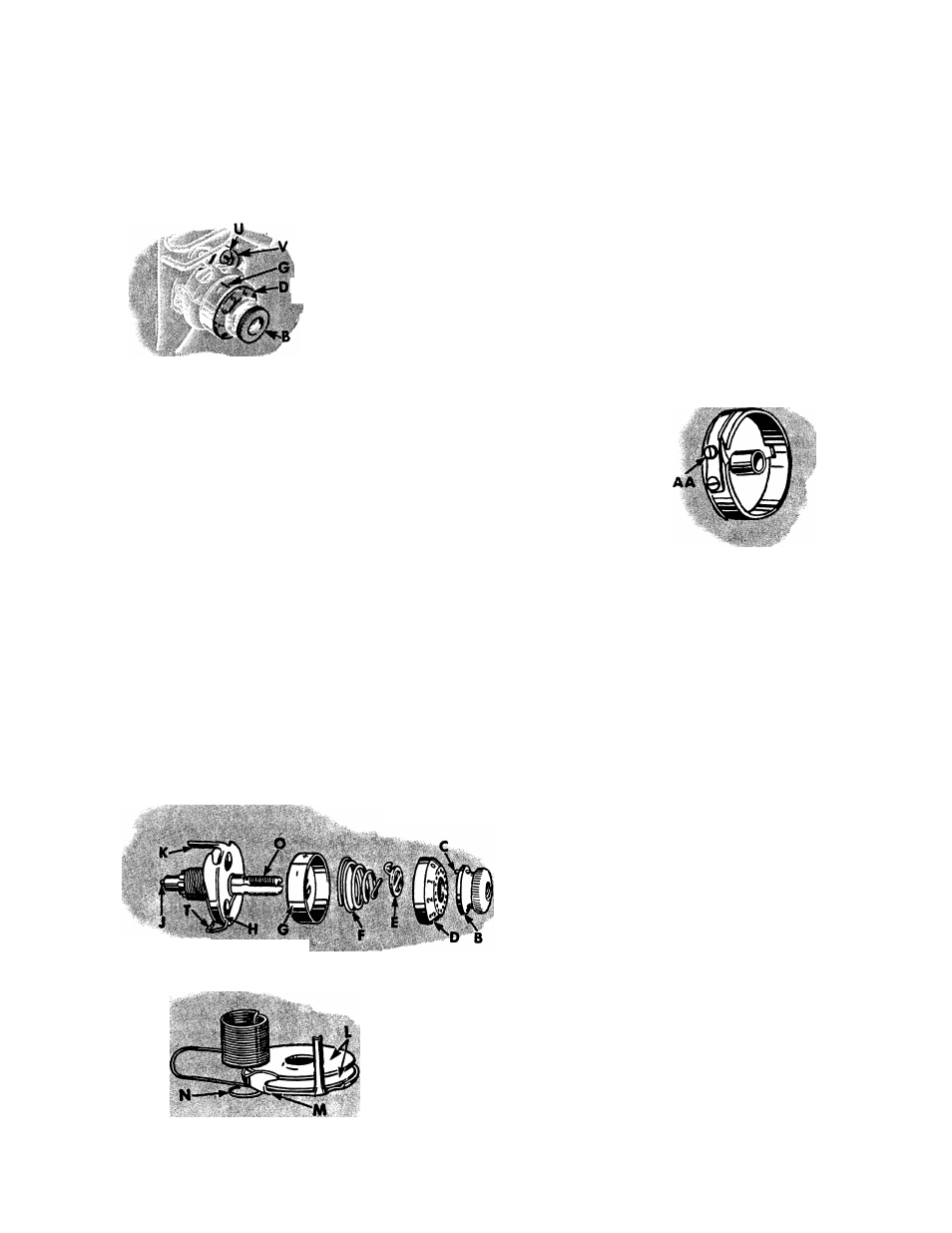

Fig. 25. Needle Thread Tension Disassembled

T O R E M O V E A N D D I S A S S E M B L E N E 4 . E T H R E A D T E N S I O N

Turn thumb nut B to left (counter-clockwise) until ‘‘O” on

numbered dial stops at cente** bne on indicator G.

To separate pin C in thumb nut B from dial

D, press in dial, unscrew thumb nut and re

move it. Then remove dial, stop washer E,

tension spring F, indicator G and tension

assembly H.

NOTE: It is not necessary to remove stud O

from machine to disassemble the thread ten

sion. It is shown removed in Fig. 25, only

to illustrate the complete assembly.

Fig. 26. Tension Disc Assembly

T O R E A S S E M B L E A N D R E P L A C E N E E D L E T H R E A D T E N S I O N

Make sure that tension releasing pin J is in place in stud O.

Place two tension discs L with their convex faces together on

tension thread guide M, then pass eyelet N of thread take-up

spring under thread guide, having coils of spring above ten

sion discs, as shown in Fig. 26.