SINGER 1371A2 User Manual

Page 43

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

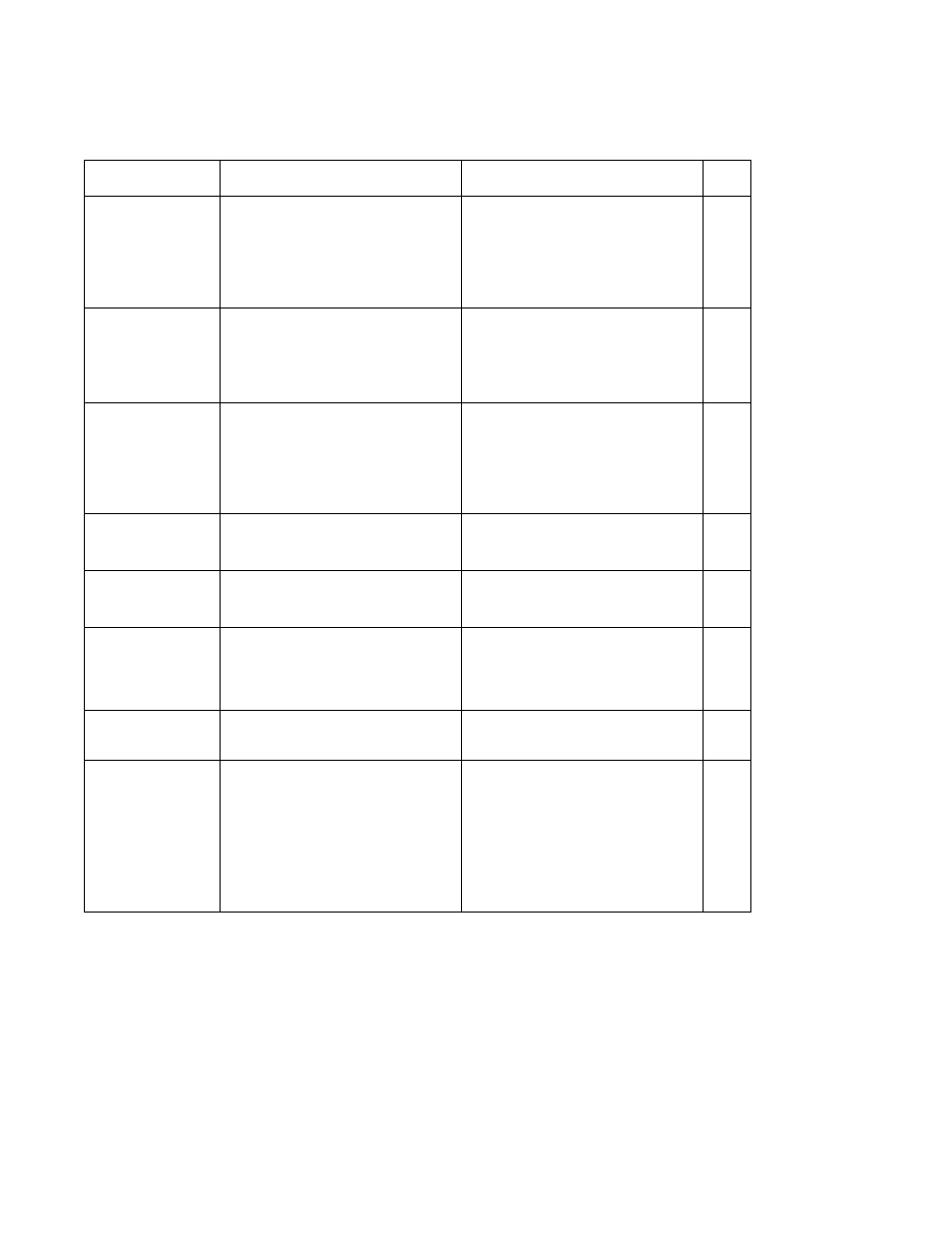

Trouble

Cause

Remedy

Page

1. Starting pedal does

not work. (The

(1) Needle plate, needle plate base or

bobbin thread trimmer is clogged wdth

O Tilt the machine head and clean them up.

work clamp arm is

fibrous dust.

O Readjust the installation of the trimmer.

not lifted up fiilly.)

(2) The needle thread trimmer is interfered

by the work clamp check or the trimer

driving plate.

or the position of the trimmer driving

plate.

31

2. Machine does not

(1) The hand stop crank is not in the

O Correct the position of the hand stop

17

reach the high

correct position.

crank.

speed even when

the pedal is step

ped down fully.

(2) The belt shifter of the speed transmitter

has not changed to the high speed

pulley.

O Lubricate the shifter driving pin.

3. A loud noise is

(1) Improper setting of the low speed cam O Readjust the setting of the low speed

25

produced with a

for small numbers of stitches.

cam.

stop-motion, or se

wing speed does

(2) The flat belt is too loose.

O Increase the belt tension by the tension

pulley.

10

not lower at the

end of sewing.

(3) The low speed V belt is too loose.

O Increase the tension of the V belt by the

motor.

8

4. Stop-motion is not

(1) Stop-motion lever needs lubrication.

O Lubricate the stop-motion lever.

12

smooth.

(2) The belt shifter of the speed transmitter

has not changed to the low speed pulley.

O Readjust.the position of the belt shifter. 31

5. The machine does

(1) Oil level in the oil reservoir is too low. OFill the lubricating oil up to "HIGH"

12

not lubricate.

mark.

(2) Oil is not circulated.

O Apply oil to the oil return felts.

12

6. Knife is dropped (1) Position of the knife tripping segment is

©Adjust the position of the driving cam so 34

during high speed

not correct.

that the knife is dropped down at a

rotation.

delayed timing.

(2) The setting of the low speed cam for

numbers of stitches is not correct.

O Correct the seting of the low speed cam.

25

7. Knife is dropped

even if the needle

thread is broken.

(1) The machine is threaded incorrectly.

O Correct the threading.

16

8. Needle is broken.

(1) The needle is bent.

O Replace the needle.

13

(2) The needle and the hook blade touch

with each other.

©Readjust the positions of the needle and

the sewing hook.

29

(3) Needle thread trimmer hits the needle © Readjust the position of the trimmer.

31

when opening its blades.

©Adjust so that the hmiting plate and the

blocking arm touch each other at the

time of starting.

31

40