Satin stitching, Purchase – SINGER 717 Scholastic User Manual

Page 25

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

satin stitching

Satin stitching, a series of cioseiy spaced zig

zag stitches that form a smooth, satin-like sur

face, is used for both practical and decorative

work, it is suitable for bar tacks when closed

up to form a satin stitch.

When you wish to produce a satin stitch, make

a test sample first so that you can adjust the

stitch length and thread tension properly. Soft

fabric may require a backing to ensure firm

satin stitching. Crisp lawn or organdy is suit

able for this purpose.

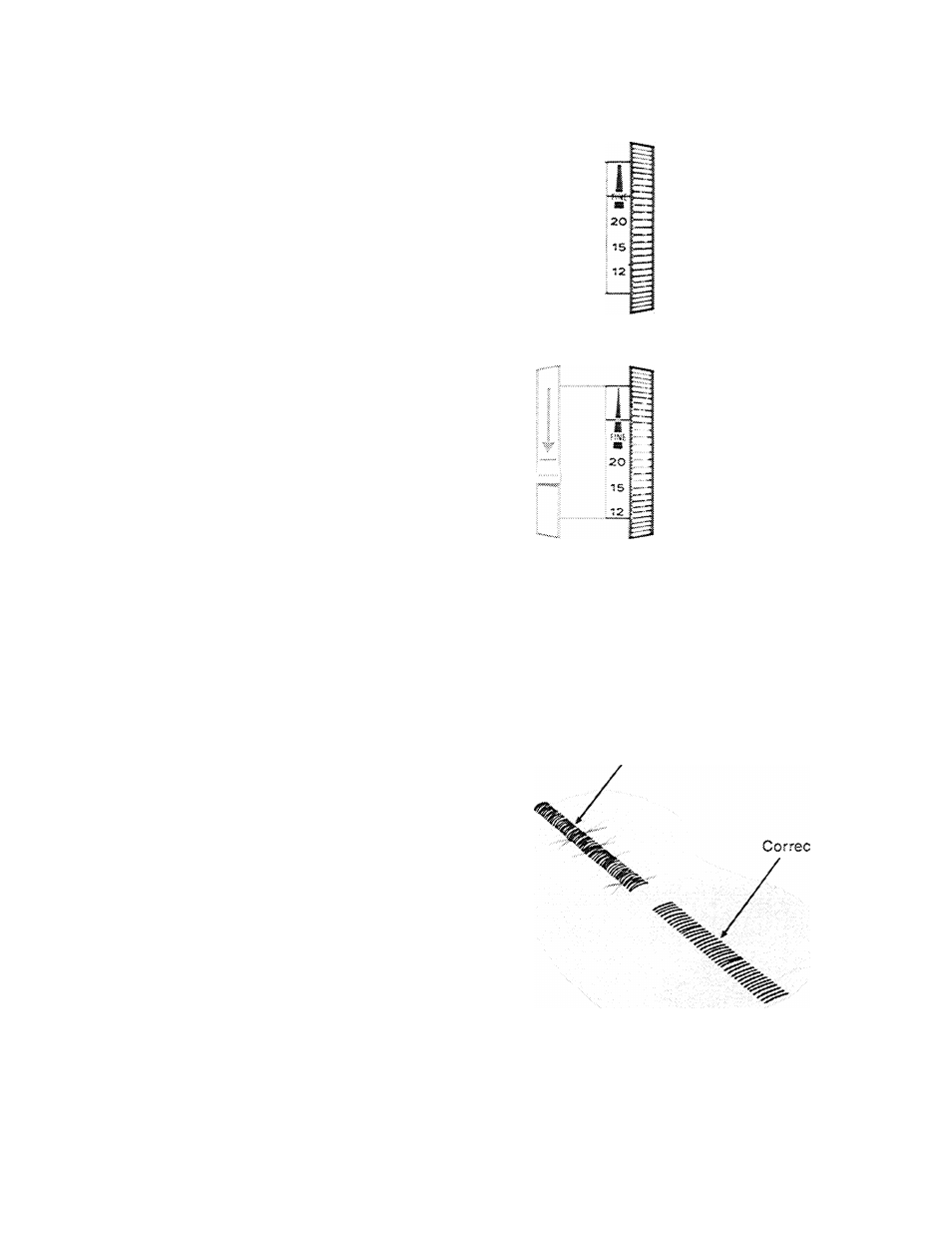

ACCESSORIES AND DIAL SETTiNGS

♦ Needle Position: A

Stitch Width: 2 to 5

♦ Stitch Control: in FINE area

♦ Zig-Zag Throat Plate

« Zig-Zag Foot or

Special Purpose Foot (see note)

Stitch Control in FINE Area

As the Dial 1$ Rotated, Stitches Close Up

Adjusting Stitch Length

1. Set stitch control dial at bottom of FINE

area,

2. Run machine at SLOW speed.

3. GraduaHy turn dial downward until stitches

are closely spaced and form a smooth sur

face.

AcJfysting Thread Tension

Satin stitching requires less tension than

straight stitching or open zig-zag stitching,

furthermore, the wider the stitch, the lighter

the tension on the thread must be. Notice the

stitching on your sample, lithe fabric is puck

ered, lower the needle-thread tension by turn-

in c the tension dial to a lower number.

Incorrect

NOTE: For best results in satin stitching, the spe

cial purpose foot is recommended (available for

purchase,

see page 43),

Adjusting Thread Tension

23