To install/tensjon plain-end blades – Sears 113.20765 User Manual

Page 9

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

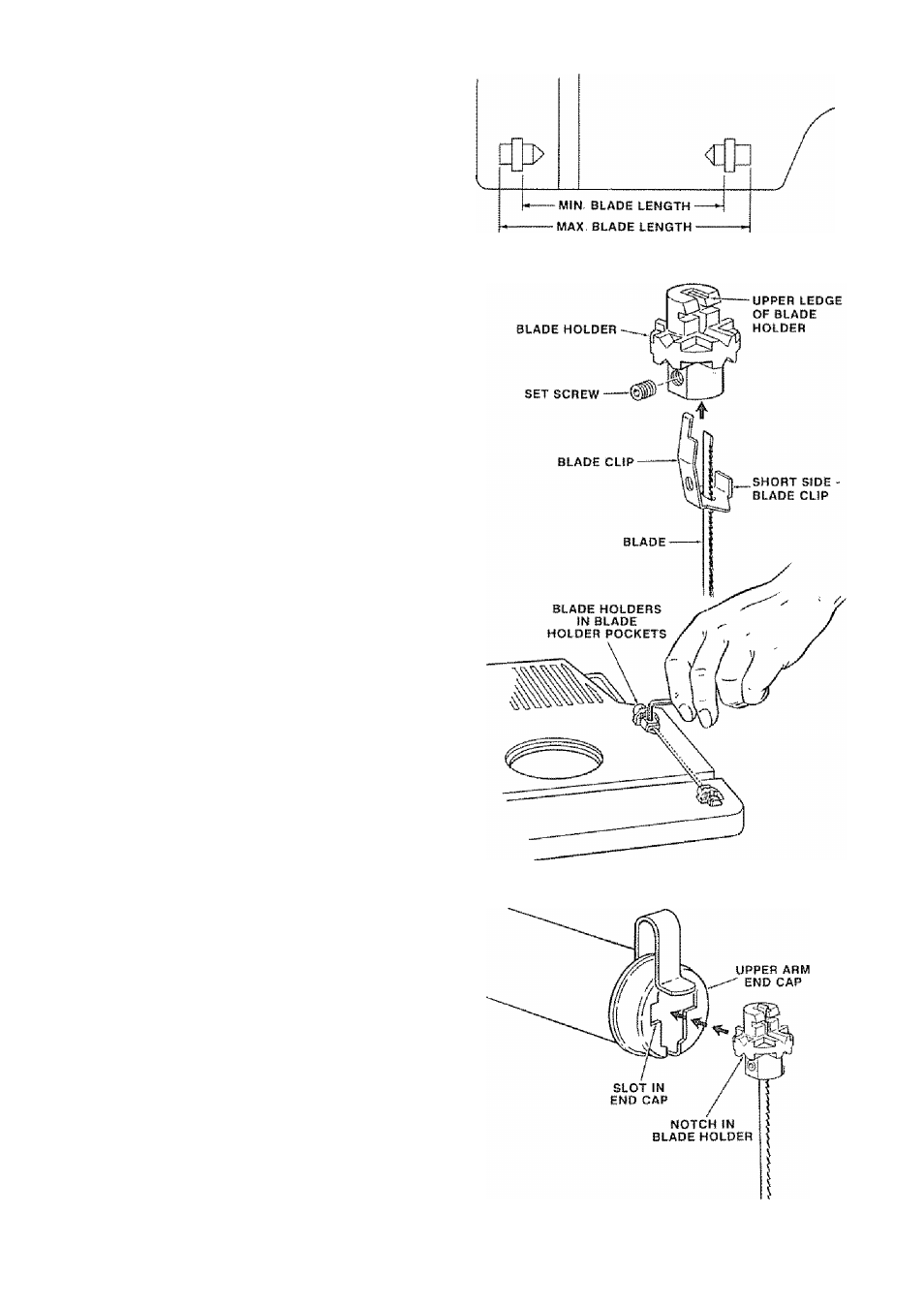

BLADE INSTALLATION AND

TENSIONING FOR PLAIN-END

OR PIN TYPE BLADES

NOTE: Included with the scroll saw are three 5"

blades. This saw can accommodate 5" to 6" plain-

end blades, and 5” pin type blades

TO INSTALL/TENSJON PLAIN-END

BLADES:

WARNING: FOR YOUR OWN SAFETY, TURN

SWITCH ‘OFF’, REMOVE KEY ANP REMOVE

PLUG FROM POWER SOURCE OUTLET BEFORE

REMOVING OR INSTALLING SAWBLADE.

NOTE: Use blade holder pockets to verify correct

blade length and positioning

1 Locate four (4) blade holders, four (4) 10-32 x 1/4

set screws, one {1) blade, four (4) blade clips, and

one (1) set screw wrench among loose parts Two

(2) extra blade holder assemblies are provided for

quick and convenient changing of blades,

2 Insert one (1) blade clipintoeach blade hoiderby

pushing clip through holder until it snaps into

place catching upperledge. Insert one 10-32 x 1/4

set screw into each blade holder

3 Insert blade into one holder by pushing short side

of blade clip towards set screw, installing blade,

and releasing side of blade clip Place holder into

blade holder pocket in table (set screw side

upward) and check for proper extension squaring

blade to opposite blade holder pocket center

point Tighten set screw with wrench provided.

4, insert blade into other holder (as described

above) Place both holders in pockets in table to

achieve proper spacing and tighten other set

screw.

5 Place holder assembly in table insert hole; make

sure the teeth are pointing downward.

BLADE HOLDER POCKETS

USED AS BLADE LENGTH GAUGE

6- Set notches in blade holders into slots inside upper

and lower arm end caps The blade holders provide

slots for orientating blade in any 90® position

NOTE; Blade holders do not touch the retainer clips after

being properly installed The purpose of the retainer

clips is to deflect the blade holders if the blade breaks