Motor, Lubrication, Recommended accessories – Sears 113.20765 User Manual

Page 19: Wiring diagram, Trouble shooting

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

MOTOR

Frequently vacuum or blow out any sawdust from

the motor

If the power cord is worn, cut, or damaged in any

way, have it replaced immediately

LUBRICATION

All of the BALL BEARINGS are packed with grease

at the factory They require no further lubrication.

Lubricate arm pivot bearings occasionally with light

weight machine grade oil, or 20 weight motor oii

Multi-purpose household lubricants may also be

used.

RECOMMENDED ACCESSORIES

Item

Leg Set ,.

Blades .

Casters .

__ _

9-22239

. . . . . . . See Catalog

9-22221 or 9-22222

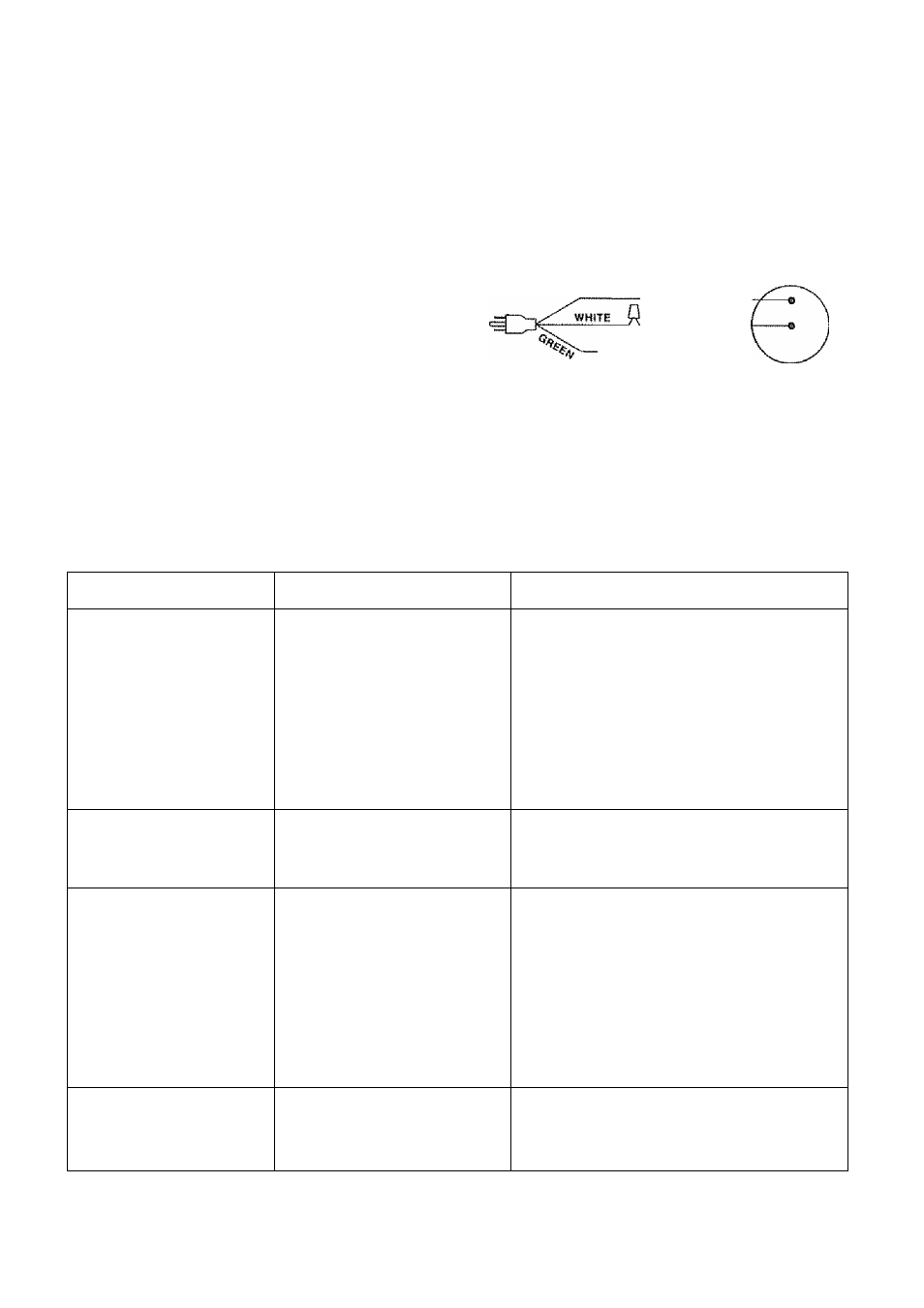

WIRING DIAGRAM

SWITCH

BLACK

WHITE

WHITE

CONNECTOH

Gf^OUND SCRSW

MOTOR

trouble shooting

WARNING: FOR YOUR OWN SAFETY, TURN SWITCH “OFF”, REMOVE KEY

AND

REMOVE

PLUG

FROM

POWER

SOURCE

OUTLET

BEFORE

TROUBLESHOOTING YOUR SCROLL SAW

TROUBLE

PROBABLE CAUSE

REMEDY

Motor will not run.

1, Defective On-Off switch.

Defective switch cord

Defective switch box receptacle

2, Motor Defective,

3 Cutting too fast,

defective blade;

mechanism jammed

1

Replace defective parts before using Scroll

Saw again

2 Consult Sears Service Any attempt to repair

this motor may create a HAZARD unless

repair Is done by a qualified service

technician. Repair service is available at your

nearest Sears Store

3- A slot has been provided in the end of the

motor shaft to insert screwdriver to

martually cycle motor Unit must be

unplugged from power source

Scroll Saw slows down

when cutting.

1 Cutting too small a radius

2 Dull blade

1 Stop feeding, and back up to the material

slightly, until the scroll saw speeds up; use

smaller blade

2 Replace blade

Blades breaking or

bending.

1 Too little tension.

2 Kink in blade caused by

cutting too small a raduis or

turning the materia! too fast

when cutting

3 Blade not set far enough in

blade holders

4 Forcing workpiece into

blade or sideloading

blade excessively

1 Adjust tension. See “Getting To Know Your

Scroll Saw Tension Setting",

2 Use correct cutting technique. See "Basic

Scroll Saw Operation" Section,

3 Remove blade holder assembly and reinstall

blade correctly in holders See “ Assembly

Blade Jnstaliatlon"

4- Do not force workpiece Allow

blade to cut- Avoid applying

excessive sidetoad.

Blade twisted or out ot line.

1 Blade Holders incorrectly set

in arm end caps

2, Slade not square to table

1 Adjust blade holders — See "Assembly -

Slade installation"

2r

Adjust blade to table - See ‘ Assembly -

Adjusting the Blade Square to Table"

19