Installing sliding guard, Iristaliing sliding guard, 1/2 in. hex nut – Sears 113.206930 User Manual

Page 9

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

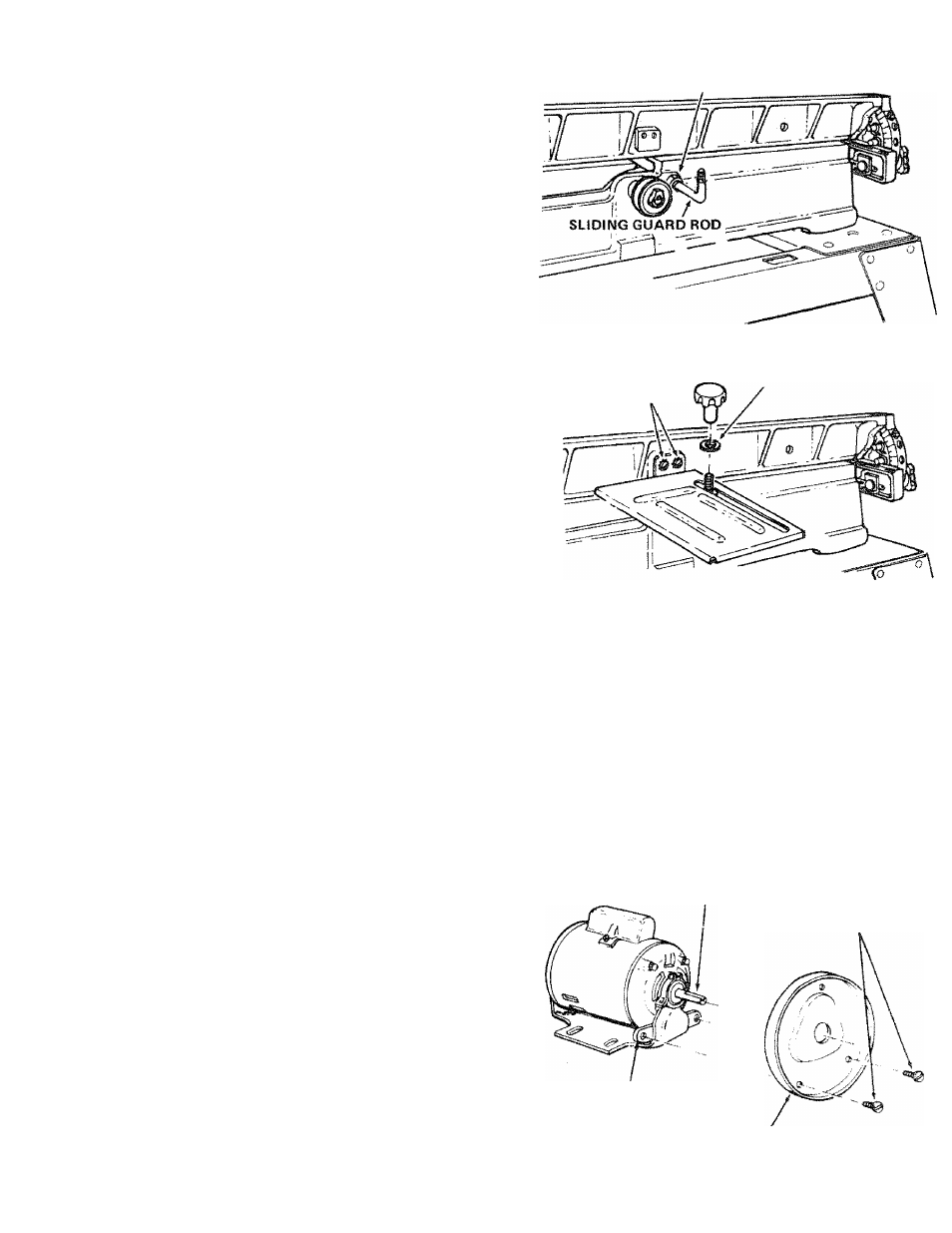

INSTALLING SLIDING GUARD

PARTS NEEDED

1 Sliding Guard

1 Sliding Guard Knob

1 Sliding Guard Rod

2 Sliding Guard Washers (one side of washer is concave)

1 Hex. Nut

M 2

in, -13

1 Spiit tockwasher 1/2 in.

2 Ext. tooth lockwashers

2 10-32x1/4 Pan Hd. Screws

1. Screw nut all the way onto long end of rod . . . place

1/2 in. lockwasher next to nut.

2. Screw rod all the way into Jointer with short end up . ..

tighten nut.

1/2 IN. HEX NUT

SLIDING GUARD KNOB

10-32x1/4 SCREWS

WASHER

{CONCAVE SIDE UP)

3. Attach sliding guard to fence with two machine screws EXT. TOOTH

and lockwashers.

LOCKWASHER^

4. Place one Sliding Guard Washer, concave side DOWN on

support rod.

5. Drop sliding guard onto rod ... place other washer, con

cave side UP on rod . . . screw on Sliding Guard Knob.

MOUNTING RECOMMENDED CRAFTSMAN

MOTOR AND BELT GUARDS

See page 5 for recommended motors.

PARTS NEEDED

4 carriage bolts, 5/16-18 x 3/4 in., flat washers, lock

washers and nuts.

1 Jointer Planer Belt Guard

1 Motor Pulley Belt Guard

1 Belt Guard Support

1 Belt Guard Support Bracket

3 Belt Guard Clips

1 Motor Pulley, 2-1/2 in. dia,

1 V-Belt

_

2 Pan Head Screws 10 - 32 x 1/2 in.

2 Hex. Hd. Screws 1/4 - 20 x 1/2 in.

2 Hex. Nuts 1/4-20

TOOLS NEEDED

Medium Screwdriver

5/32 in. Setscrew Wrench (furnished with Jointer)

1/2 and 7/16 in. Wrenches

1. Place motor on your workbench with 5/8 in. dia. shaft

(with key way) facing you.

2. Attach guard support to bracket with two screws.

NOTE: The holes in the bracket are not threaded, but

the screws are "thread cutting screws" and will cut a

thread as they are tightened.

S/8 IN. DIA. SHAFT

BELT GUARD

SUPPORT

BRACKET

PAN HD. SCREWS

BELT

GUARD

SUPPORT