Lubrication, Wheels, Blade control handle – Sears 247.37033 User Manual

Page 12

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Rinse the foam filter thoroughly in clear water.

Wrap in a clean cloth and squeeze (do not twist)

until completely dry, or allow to air dry.

Saturate with engine oil and squeeze (don’t

twist) to distribute oil and remove excess oil.

If necessary, replace paper filter (do not attempt

to clean). Install new filter on base.

Swing cover upward and align hinge on the

cover with that on the engine.

Tighten cover screw securely.

Clean Engine

Clean engine periodically. Remove dirt and

debris with a cloth or brush.

Frequently remove grass clippings, dirt and

debris from cooling fins, air intake screen and

levers and linkage. This will help ensure

adequate cooling and correct engine speed.

NOTE: Do not clean with a forceful spray of water as

water could contaminate the fuel system.

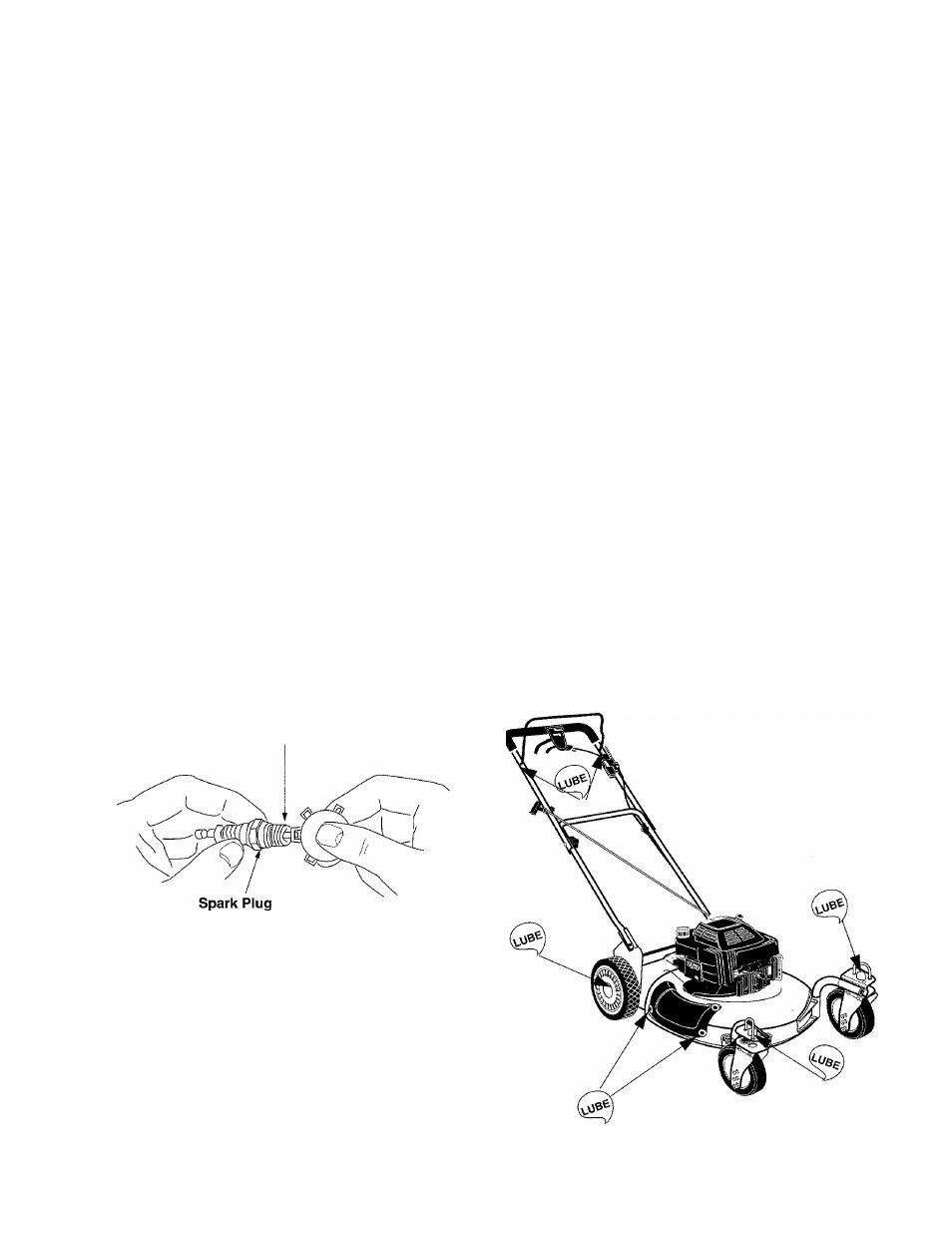

Spark Plug

• Clean spark plug and reset gap to .030" at least

once a season or every 50 hours of operation.

See Figure 10. Spark plug replacement is

recommended at the start of each season. Refer

to engine parts list for correct spark plug type.

NOTE: Do not sandblast spark plug. Sparkplug

should be cleaned by scraping or wire brushing and

washing with a commercial solvent.

Feeler gap .030”

Figure 10

Muffler

A

WARNING: Do not operate the lawn

mower without a muffler, or tamper with

the exhaust system. Damaged mufflers or

spark arresters could create a fire hazard.

Temperature of muffler and nearby areas

may exceed 150° F(65°C).

Inspect periodically, and replace if necessary. If

your engine is equipped with a spark arrester

screen assembly, remove every 50 hours for

cleaning and inspection. Replace if damaged.

LUBRICATION

(Refer to Figure 11.)

Wheels

•

Lubricate the wheels at least once a season with

light oil or engine oil. Also, if the wheels are

removed for any reason, lubricate the surface of

the axle bolt and the inner surface of the wheel

with light oil.

Caster Assembly

•

Grease fittings are provided for easy lubrication

of the swivel pins located on the front caster

assembly. Use a grease gun to lubricate the

casters every 25 operating hours or so.

Blade Control Handle

•

Lubricate the pivot points on the blade control

handle and the brake cable at least once a

season with light oil. The blade control must

operate freely In both directions.

Figure 11

14