A caution – Carrier 48N User Manual

Page 5

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Table 1—Maximum Gas Flow Capacity of Pipe in Cubic Feet of Gas Per Hour for Gas

Pressures of 0.5 PSIG or Less and a Pressure Drop of 0.5 inch Water Coiumn

(Based on a 0.60 Specific Gravity Gas)

Nominal

Iron Pipe,

Size,

Inches

Internal

Diameter,

Inches

Length of Pipe, Feet*

10

20

30

40

50

60

70

80

90

100

125

150

175

200

1/2

.622

175

120

97

82

73

66

61

57

53

50

44

40

—

—

3/4

.824

360

250

200

170

151

138

125

118

110

103

93

84

77

72

1

1.049

680

455

375

320

285

260

240

220

205

195

175

160

145

135

1-1/4

1.380

1,400

950

770

600

580

530

490

460

430

400

360

325

300

280

1-1/2

1.610

2,100

1,460

1,180

990

900

810

750

690

650

620

550

500

460

430

Ref: Table 0^4, NFPA 54—1984

*This length includes an ordinary number of fittings.

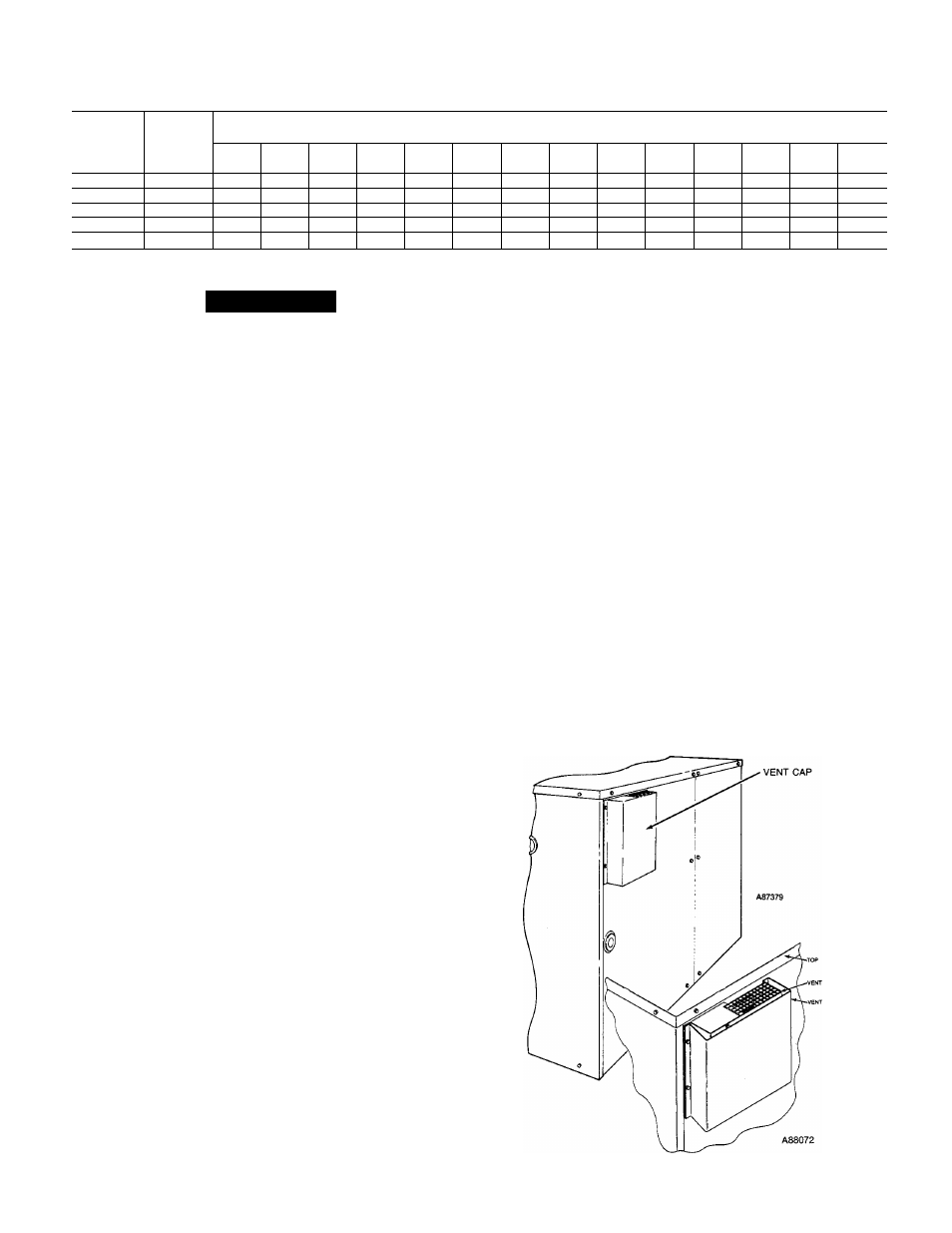

A CAUTION

The venting system is designed to ensure proper vent

ing. The vent cap assembly must be installed as indi

cated

in

this

section

of

the

unit

Installation

Instructions.

NOTE:

Screw holes in the flue assembly and the unit flue

panel are

not

symmetrically located; thereby, ensuring

proper orientation when installing these components.

Refer to Fig. 6 and install the vent cap as follows:

1. Place vent cap assembly over flue panel, orient screw

holes in vent cap with holes in flue panel, and secure

vent cap in place by inserting the single screw on the

right side of vent cap.

2. Place the vent cap guard over the vent cap, orient holes

in vent cap guard with holes in vent cap and flue panel.

Secure the entire assembly with the remaining two

screws on the left side of vent cap and vent cap guard

assembly.

Step 4—Gas Piping

The gas supply pipe enters the unit through the access hole

provided. The gas connection to the unit is made to the

1/2-in. FPT gas inlet on the manual shutoff or gas valve.

Install a separate gas supply line that runs directly from

the meter to the heating section. Refer to Table 1 and the

National Fuel Gas Code for gas pipe sizing.

Do not use cast-

iron pipe.

Check the local utihty for recommendations con

cerning existing lines. Choose a supply pipe that is large

enough to keep the pressure loss as low as practical.

Never

use pipe smaller than the 1/2-in. FPT gas inlet on the unit

gas valve.

When instaUing the gas supply hne, observe local codes per

taining to gas pipe installations. Refer to the National Fuel

Gas Code ANSI Z223.1-1984 (In Canada, CAN/CGA

B 149.1, (2)-M86) or NFPA 54-1984 in the absence of local

buUding codes. Adhere to the following pertinent recom

mendations:

1. Avoid low spots in long runs of pipe. Grade aU pipe

1/4-in. in every 15-ft to prevent traps. Grade all hori

zontal runs downward to risers. Use risers to connect

to heating section and to meter.

2. Protect all segments of piping system against physical

and thermal damage. Support all piping with appropri

ate straps, hangers, etc. Use a minimum of one hanger

every 6-ft. For pipe sizes larger than 1/2-in., follow rec

ommendations of national codes.

3. Apply joint compound (pipe dope) sparingly and only

to male threads of joint when making pipe connections.

Use only pipe dope that is resistant to action of lique

fied petroleum gases as specified by local and/or

national codes.

Never use teflon tape.

5.

6

.

4. Install sediment trap in riser leading to heating sec

tion. This drip leg functions as a trap for dirt and con

densate. Install trap where condensate can not freeze.

Install this sediment trap by connecting a piping tee to

riser leading to heating section, so that straight-

through section of tee is vertical. See Fig. 7. Then, con

nect capped nipple into lower end of tee. Extend

capped nipple below level of gas controls.

Install an accessible, external, manual main shut-off

valve in gas supply pipe within 6-ft of heating section.

Install ground-joint union close to heating section

between unit manual shutoff and external manual main

shut-off valve.

7. Pressure-test all gas piping in accordance with local

and national plumbing and gas codes before connecting

piping to unit.

NOTE:

When pressure testing the gas supply system

after

the gas supply piping has been coimected to the unit gas

valve, the supply piping must be disconnected from the gas

vedve during any pressure testing of the piping systems at

test pressure in excess of 0.5 psig. When pressure testing

the gas supply piping system at test pressures equal to or

less than 0.5 psig, the unit heating section must be isolated

from the gas piping system by closing the external main

manual shut-off valve and slightly opening the ground-joint

union.

Fig. 6—Vent Cap Assembly